Insert valve for sectional radiator

A radiator and segmented technology, applied in the field of insertion valve, can solve the problems of high production cost and complex structure of the casing, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

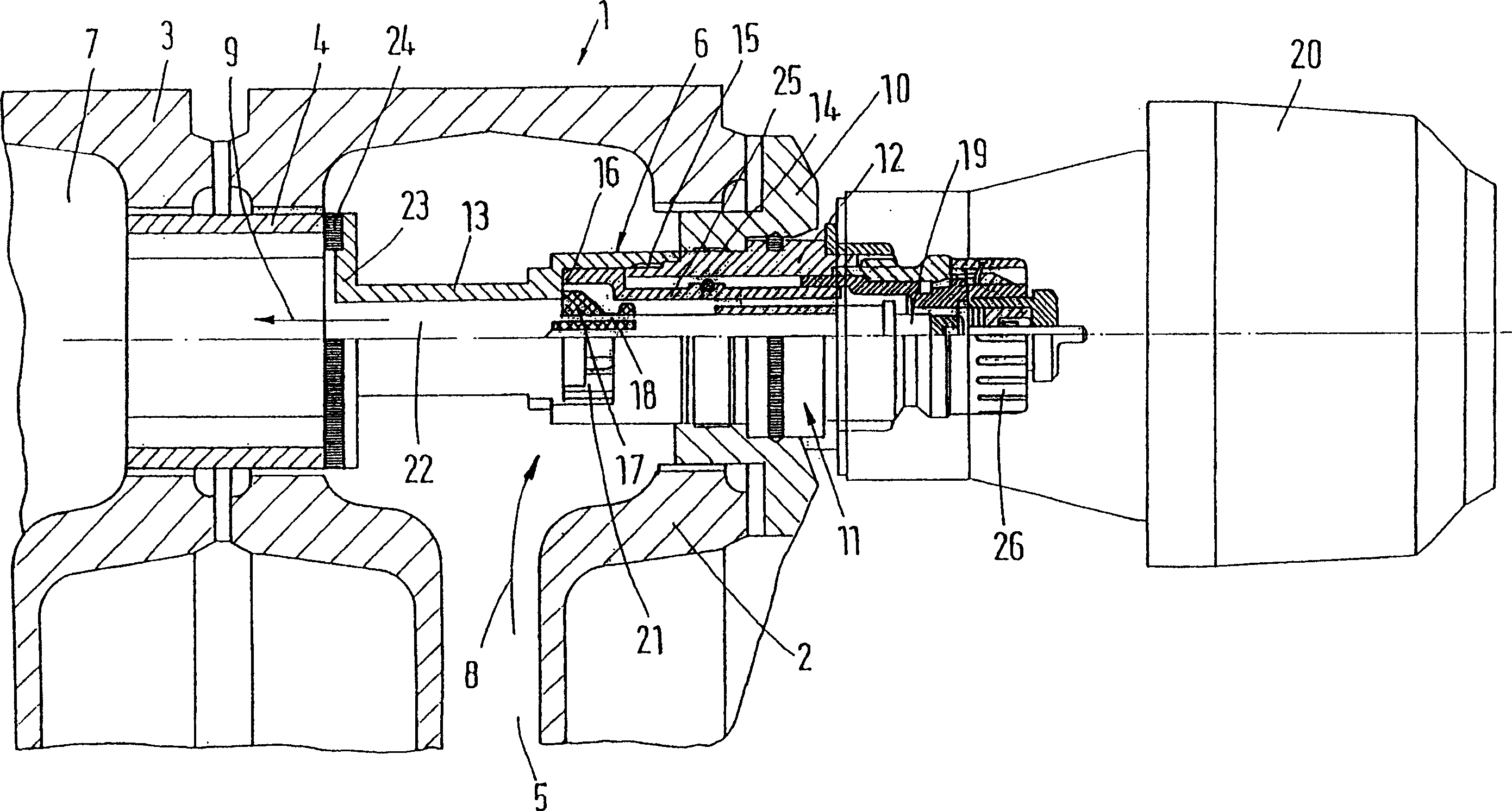

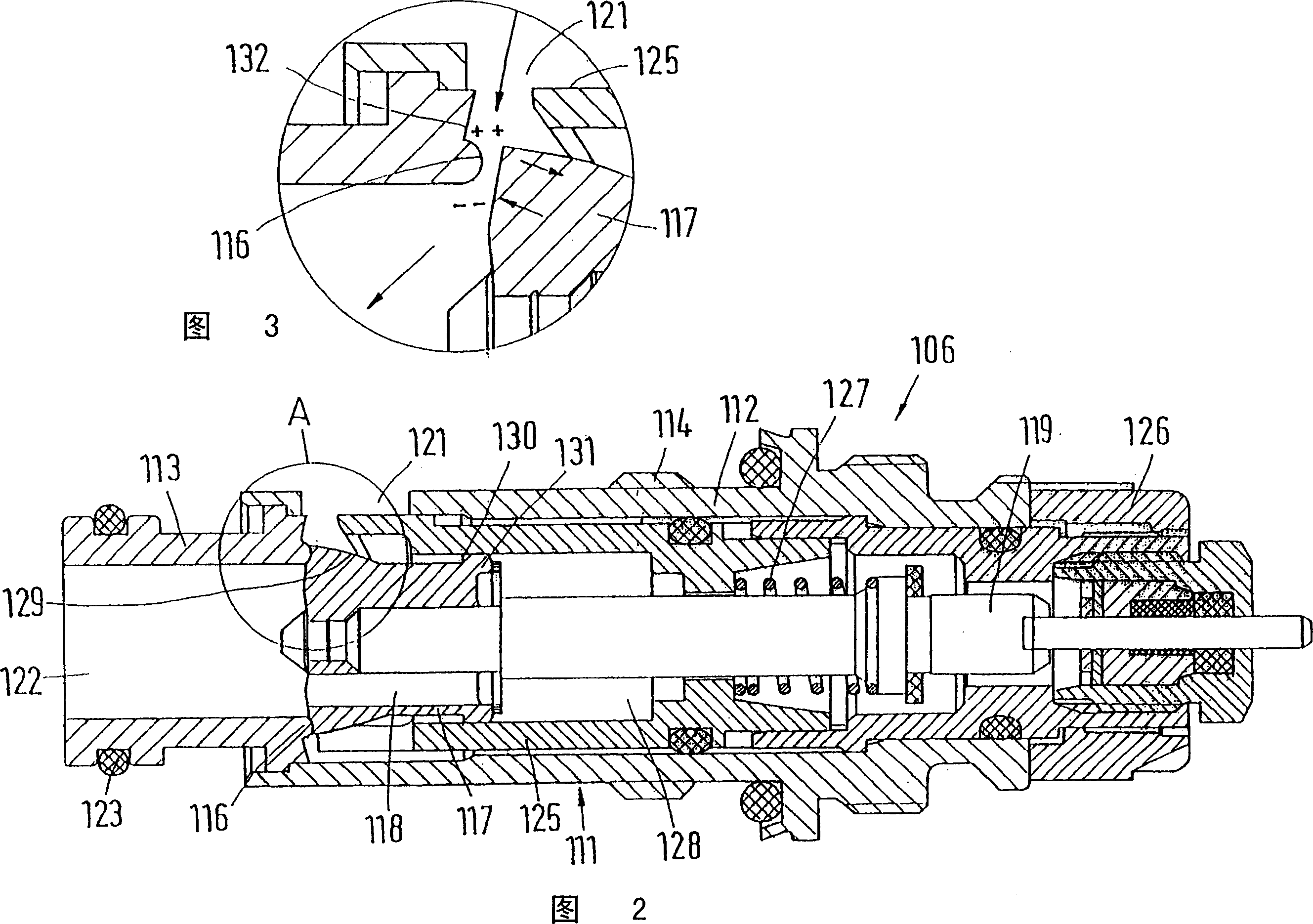

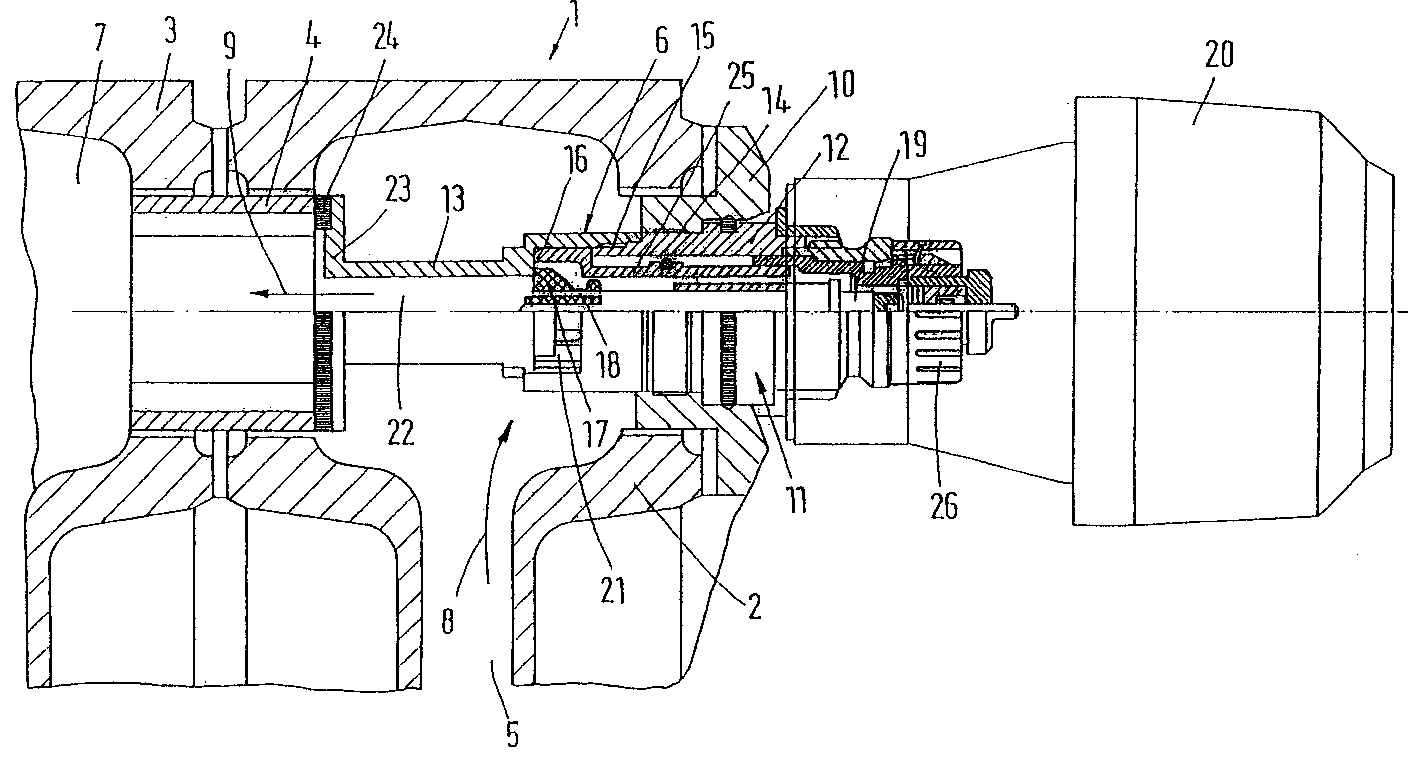

[0021] The segmented radiator 1 has a number of segments 2 , 3 which are connected by means of a partly right-hand threaded and partly left-hand threaded bushing 4 . The cavity 5 of the first section 2 is equipped with a positive flow connection at the bottom end. An insertion valve 6 controls the flow of the heating medium from the cavity 5 to the cavity 7 of the second section 3, which is connected to the return connection via a plurality of other sections. Arrows 8, 9 indicate the flow process.

[0022] The plug-in valve 6 is fixed on the end face of the first section 2 by a threaded sleeve 10 . It has a housing 11 with a screw-in 12 and a shoulder 13 . The screw-in part 12 is connected to the threaded sleeve 10 via a thread 14 and to the shoulder 13 via a thread 15 . The shoulder has a valve seat 16 which cooperates with a closure 17 which has a pressure relief channel 18 and is actuated by a thermostat 20 via a valve rod 19 . Other features resulting in pressure relie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com