Wastegate devices for internal combustion engines

A valve device, internal combustion engine technology, applied in the direction of valve device, exhaust gas recirculation, charging system, etc., can solve the problems of increased wear, increased friction, increased adjustment force, etc., and achieve high chemical resistance and good slip performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

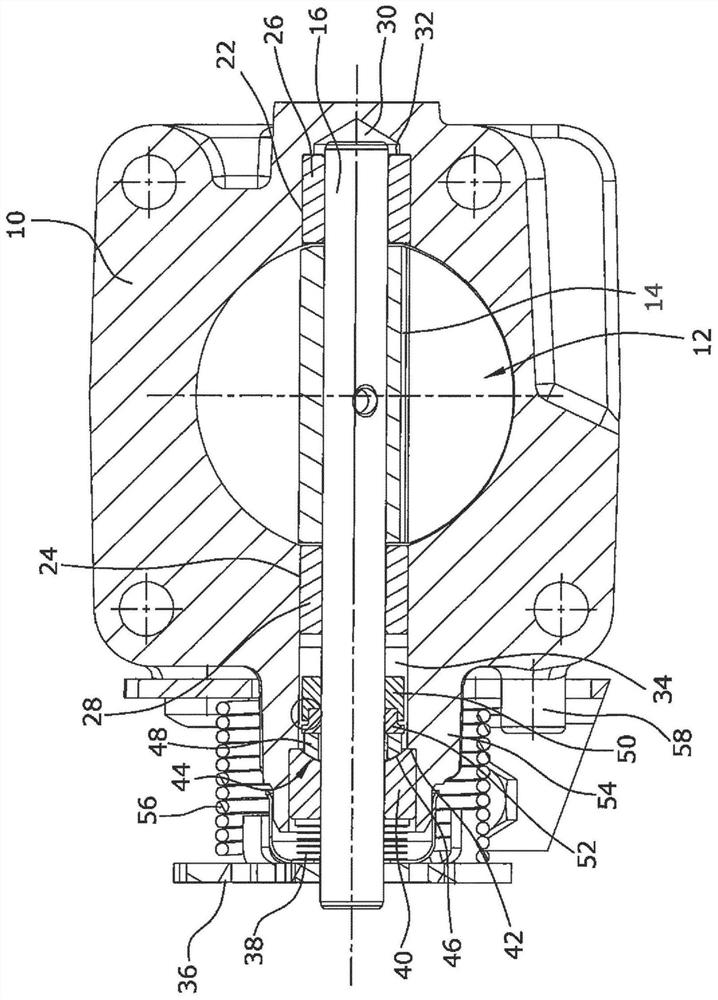

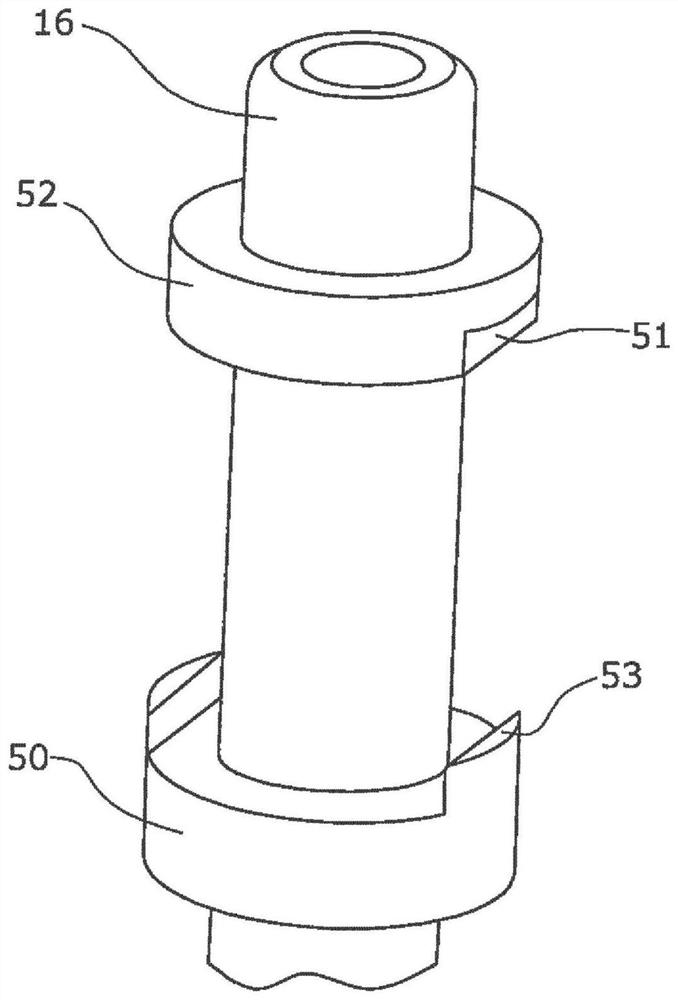

[0025] The wastegate arrangement according to the invention consists of a flow-through housing 10 in which a flow channel 12 is formed. The flow-free cross section of the flow channel 12 is adjusted by turning the valve body 14 in the flow channel 12 . For this purpose, the valve body 14 is fastened to a shaft part 16 , which is mounted centrally on both sides in the flow-through housing 10 , so that the valve body 14 is divided by the shaft part 16 into two valve halves. Opposed bearing receptacles 22 , 24 are formed on the flow-through housing 10 for support, in which bearing receptacles 26 , 28 are respectively arranged, the bearings being designed as radial bearings.

[0026] One end of the shaft part 16 protrudes into a blind hole 30 which serves as the bearing receptacle 22 and in which the bearing 26 is arranged. The bearing 26 rests axially with its one end on a step 32 formed in the blind hole 30 , while the other end of the bearing 26 points toward the flow channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com