High-performance HIPS (High Impact Polystyrene) resin composition and preparation method thereof

A resin composition and high-performance technology, which is applied in the field of high-performance HIPS resin composition and its preparation, can solve the problems of ultra-high molecular weight polyethylene molding difficulty and high price, and achieve the effects of excellent performance, low cost and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

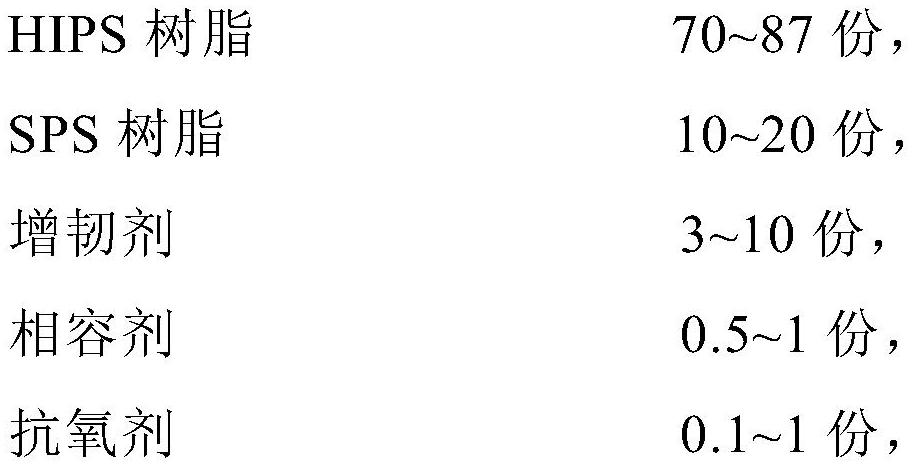

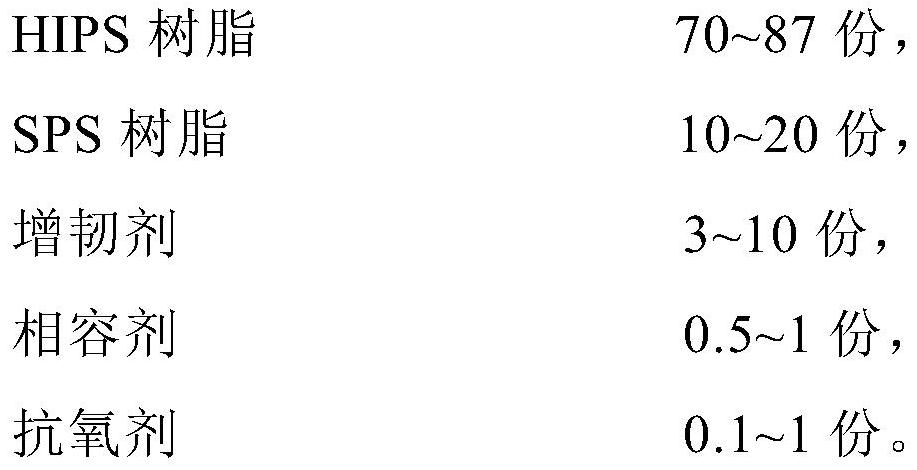

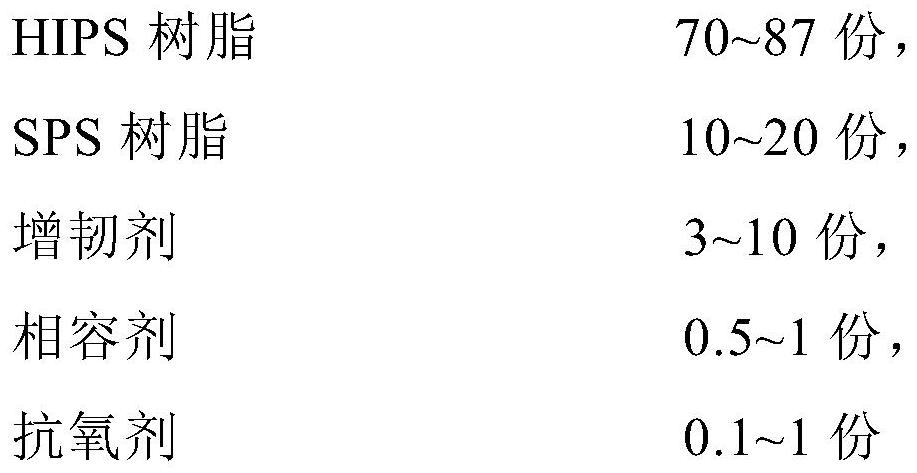

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~7

[0027] The preparation method of high-performance HIPS resin includes the following steps: according to the weight parts of the formula components in Table 1 and Table 2, the raw materials are added to a high-speed mixer and fully mixed, and then placed in a screw machine, and extruded at a temperature of 220 ° C. And 500 rev / min screw speed for melt extrusion, cooling and granulation to obtain the product.

[0028] Wherein, the raw materials of Table 1 and Table 2 are as follows:

[0029] HIPS1: Taihua HP8250, melt index 5.5g / 10min, notched impact strength 11kJ / m 2 ;

[0030] HIPS2: Taihua HP825T, melt index 11g / 10min, notched impact strength 9kJ / m 2 ;

[0031] SPS: purchased from Idemitsu, Japan, with a weight average molecular weight of 150,000;

[0032] Toughening agent 1: Rizhisheng MAH-g-POE, MAH content 0.6-0.8%;

[0033] Toughening agent 2: Rizhisheng MAH-g-SBS, MAH content 1.5%;

[0034] Toughening agent 3: Rizhisheng MAH-g-SEBS, MAH content 0.5-0.8%;

[0035] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com