Environment-friendly fireproof silicone rubber and preparation method thereof

A technology of silicone rubber and thermally vulcanized silicone rubber is applied in the field of environment-friendly fire-resistant silicone rubber and its preparation, which can solve the problems of unsatisfactory fire-resistance, insufficient environmental protection, and decreased environmental protection, so as to improve environmental protection, fire-resistance, and insulation. , Improve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

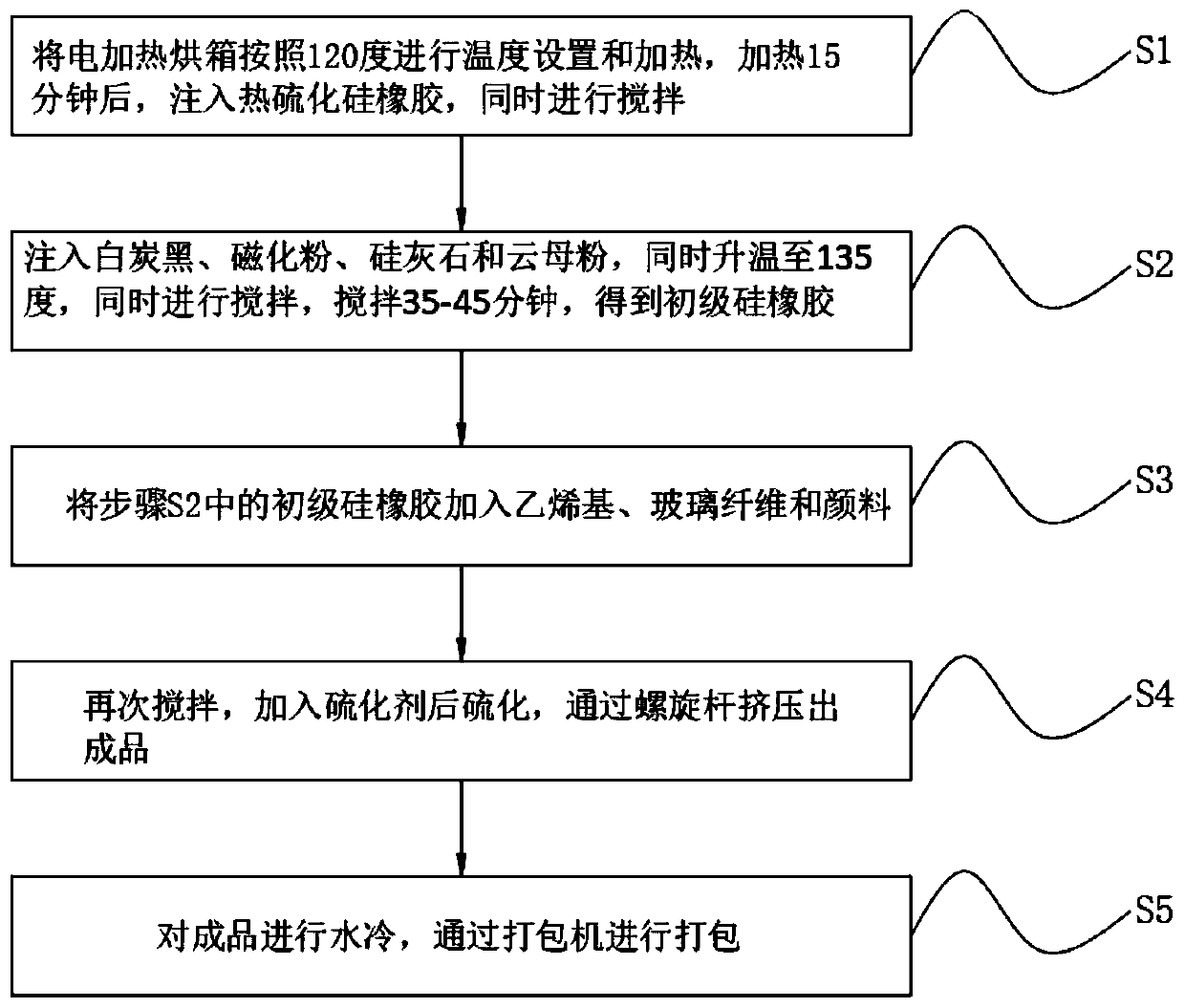

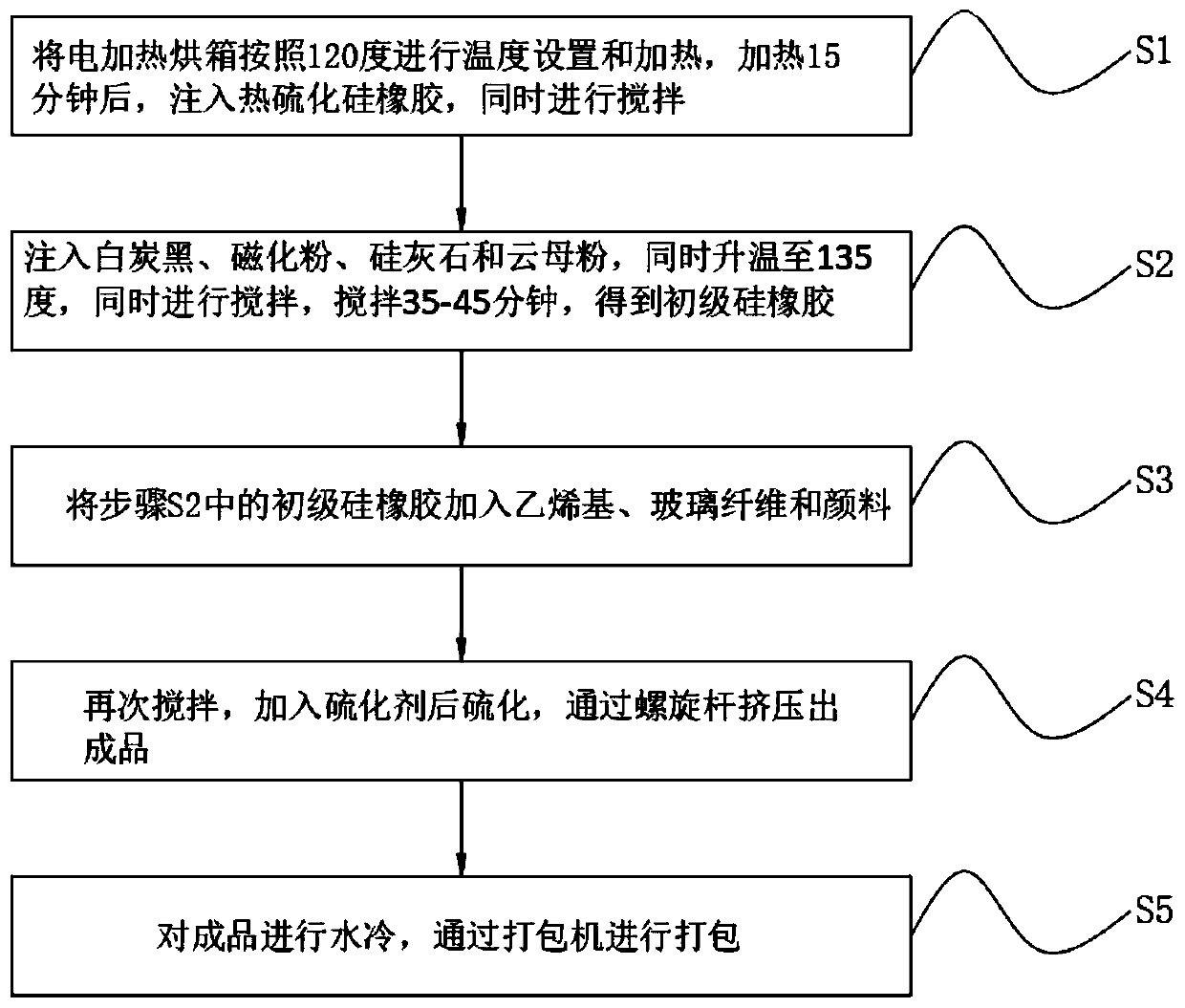

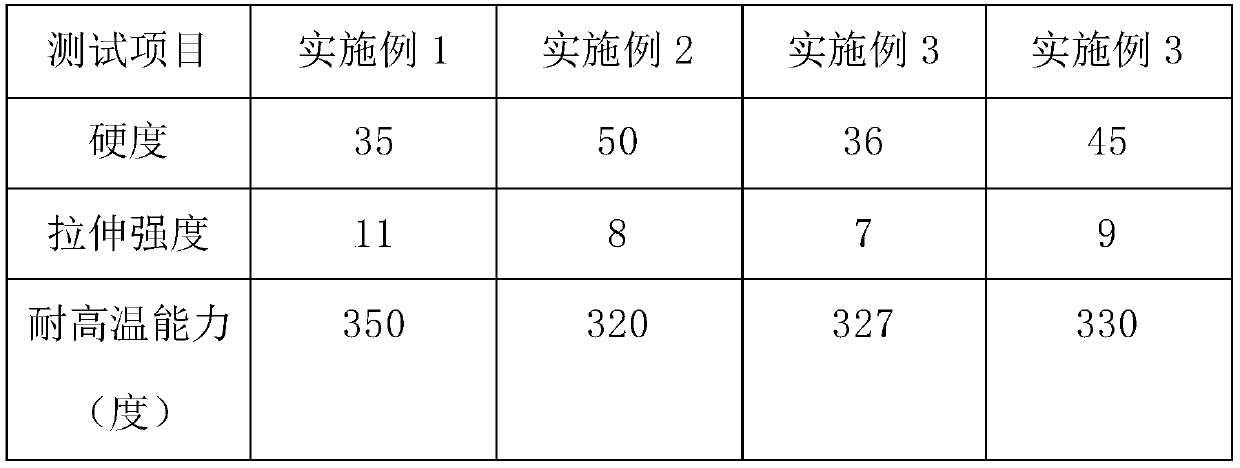

[0025] Embodiment 1: as figure 1 As shown, the present invention provides a technical solution, an environmentally friendly and fireproof silicone rubber, comprising the following raw materials in parts by weight: 100-150 parts of heat vulcanized silicone rubber, 1-5 parts of vulcanizing agent, 7-13 parts of vinyl, white 9-15 parts of carbon black, 2-6 parts of magnetized powder, 7-15 parts of glass fiber, 0-10 parts of pigment, 7-13 parts of wollastonite and 8-10 parts of mica powder.

[0026] According to the above technical scheme, it is made of the following components by weight: 120 parts of heat vulcanized silicone rubber, 3 parts of vulcanizing agent, 8 parts of vinyl, 12 parts of white carbon black, 2 parts of magnetized powder, 12 parts of glass fiber, 3 parts of pigment 8 parts, 8 parts of wollastonite and 8 parts of mica powder.

[0027] A method for preparing an environment-friendly and fire-resistant silicone rubber, comprising the steps of:

[0028] S1. Set the...

Embodiment 2

[0040] Embodiment 2: as figure 1 As shown, the present invention provides a technical solution, an environmentally friendly and fireproof silicone rubber, comprising the following raw materials in parts by weight: 100-150 parts of heat vulcanized silicone rubber, 1-5 parts of vulcanizing agent, 7-13 parts of vinyl, white 9-15 parts of carbon black, 2-6 parts of magnetized powder, 7-15 parts of glass fiber, 0-10 parts of pigment, 7-13 parts of wollastonite and 8-10 parts of mica powder.

[0041] According to the above technical scheme, it is made of the following components by weight: 123 parts of heat vulcanized silicone rubber, 1 part of vulcanizing agent, 7 parts of vinyl, 9 parts of white carbon black, 2 parts of magnetized powder, 7 parts of glass fiber, 5 parts of pigment 7 parts, 7 parts of wollastonite and 9 parts of mica powder.

[0042] A method for preparing an environment-friendly and fire-resistant silicone rubber, comprising the steps of:

[0043] S1. Set the te...

Embodiment 3

[0055] Embodiment 3: asfigure 1 As shown, the present invention provides a technical solution, an environmentally friendly and fireproof silicone rubber, comprising the following raw materials in parts by weight: 100-150 parts of heat vulcanized silicone rubber, 1-5 parts of vulcanizing agent, 7-13 parts of vinyl, white 9-15 parts of carbon black, 2-6 parts of magnetized powder, 7-15 parts of glass fiber, 0-10 parts of pigment, 7-13 parts of wollastonite and 8-10 parts of mica powder.

[0056] According to the above technical scheme, it is made of the following components by weight: 145 parts of heat vulcanized silicone rubber, 4 parts of vulcanizing agent, 8 parts of vinyl, 15 parts of white carbon black, 6 parts of magnetized powder, 15 parts of glass fiber, 7 parts of pigment 7 parts, 7 parts of wollastonite and 8 parts of mica powder.

[0057] A method for preparing an environment-friendly and fire-resistant silicone rubber, comprising the steps of:

[0058] S1. Set the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com