Constant pressure control valve of large-flow high-pressure plunger pump

A high-pressure plunger pump, constant pressure control technology, applied in the direction of fluid pressure actuating device, servo motor assembly, mechanical equipment, etc., can solve the problems of large external size of control valve, unsatisfactory control valve regulation ability, etc., to achieve compact shape , The spring adjustment force is small, the effect of reducing the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

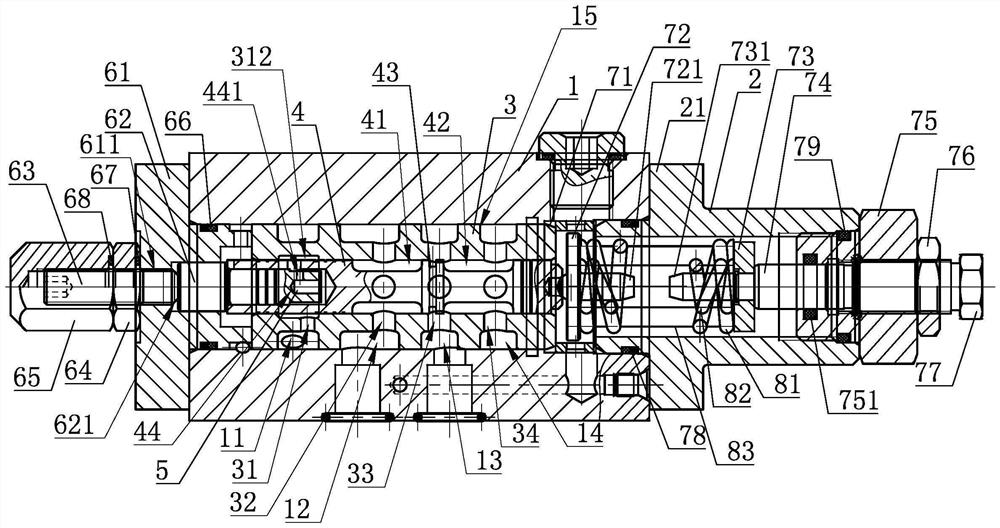

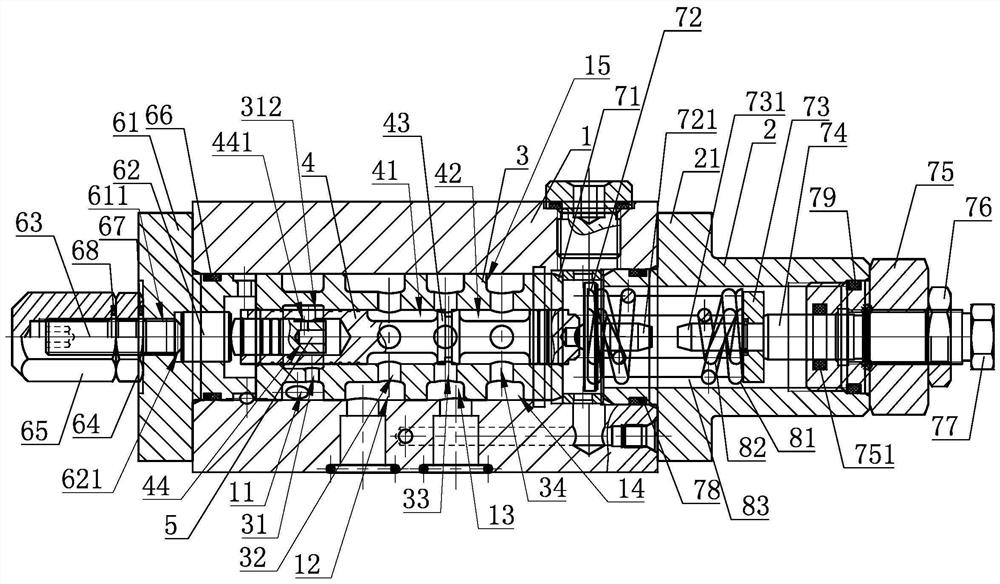

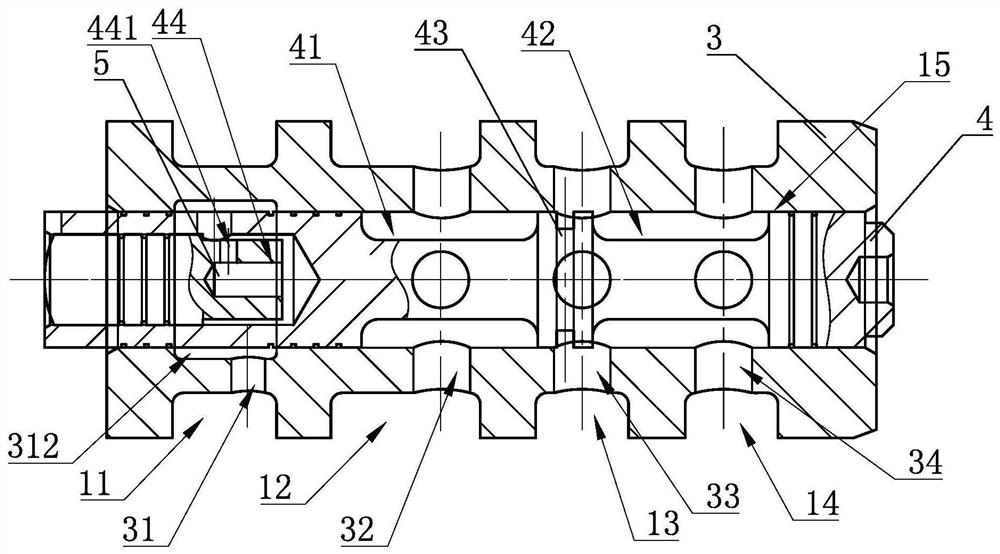

[0021]As shown in the figure, a constant pressure control valve of a high-flow high-pressure plunger pump includes a valve body 1, a mounting seat 2, a valve core assembly, a limit ejector rod assembly, and a pressure regulating spring assembly whose main body is located in the mounting seat 2. The mounting seat 2 is fixedly connected to the front end of the valve body 1, and the front end of the limit ejector rod assembly is fixedly connected to the rear end of the valve body 1. The valve body 1 is radially opened with a first channel 11 and a second channel 12 from back to front. , the third passage 13 and the leakage passage 14, the first passage 11 and the second passage 12 communicate with the outlet of the high-pressure plunger pump, the third passage 13 communicates with the large chamber of the variable cylinder, and the valve body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com