Exhaust turbocharger with bypass valve

An exhaust gas turbine and supercharger technology, which is applied in gas turbine devices, machines/engines, jet propulsion devices, etc., can solve the problems of small mass and small structure space, and achieve the effect of small power consumption requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

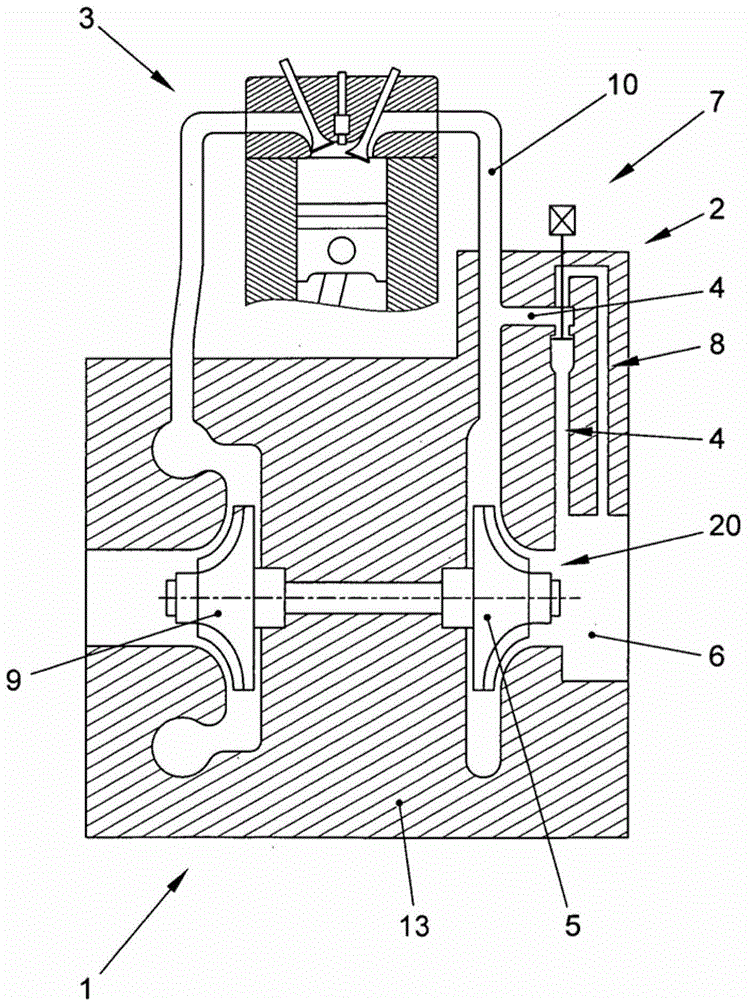

[0025] figure 1 An exhaust gas turbocharger 1 of an internal combustion engine 3 is shown. The exhaust gas turbocharger 1 has a compressor 9 on the intake side of the internal combustion engine and a turbine 5 on the exhaust side of the internal combustion engine. A bypass channel 4 is provided in the housing 13 of the exhaust gas turbocharger 1 for bypassing the turbine 5 . The bypass channel 4 connects the exhaust gas pressure line 10 to the outlet section 6 of the turbine. A bypass valve 2 for closing the bypass channel 4 is arranged in the bypass channel 4 . The embodiment shown has a section of bypass channel 4 , which can also be referred to as a branch of exhaust gas pressure line 10 , which is delimited by bypass valve 2 and exhaust gas pressure line 10 . A compensating line 8 connects the recess in the region of the bypass valve 2 to the outlet section 6 , so that the same pressure always prevails in the recess as in the outlet section 6 .

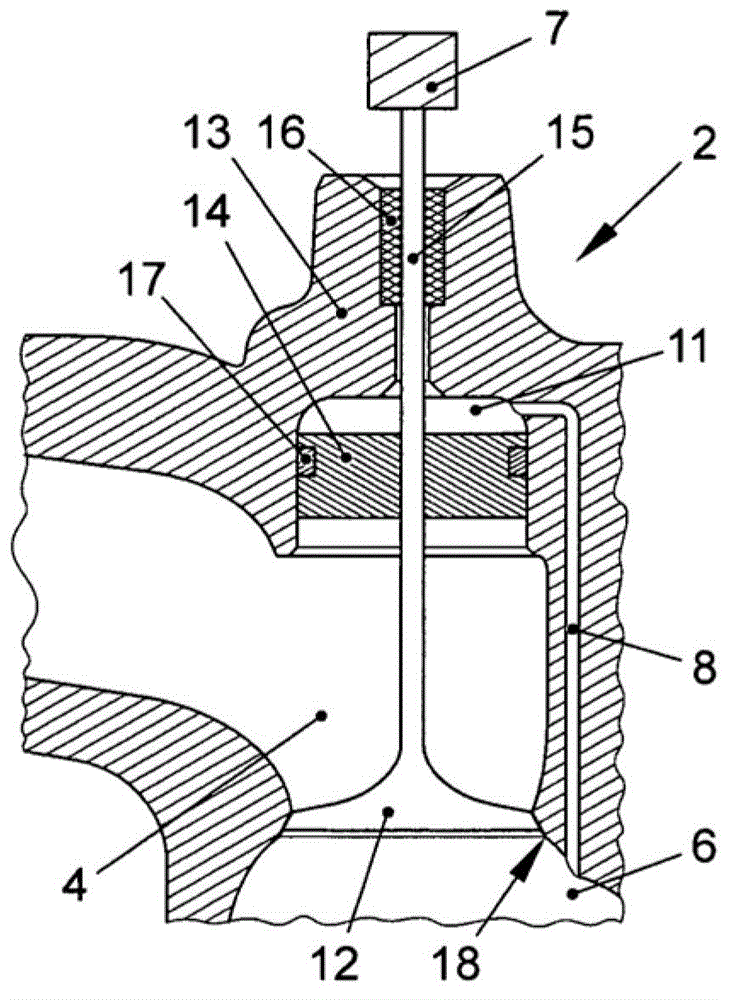

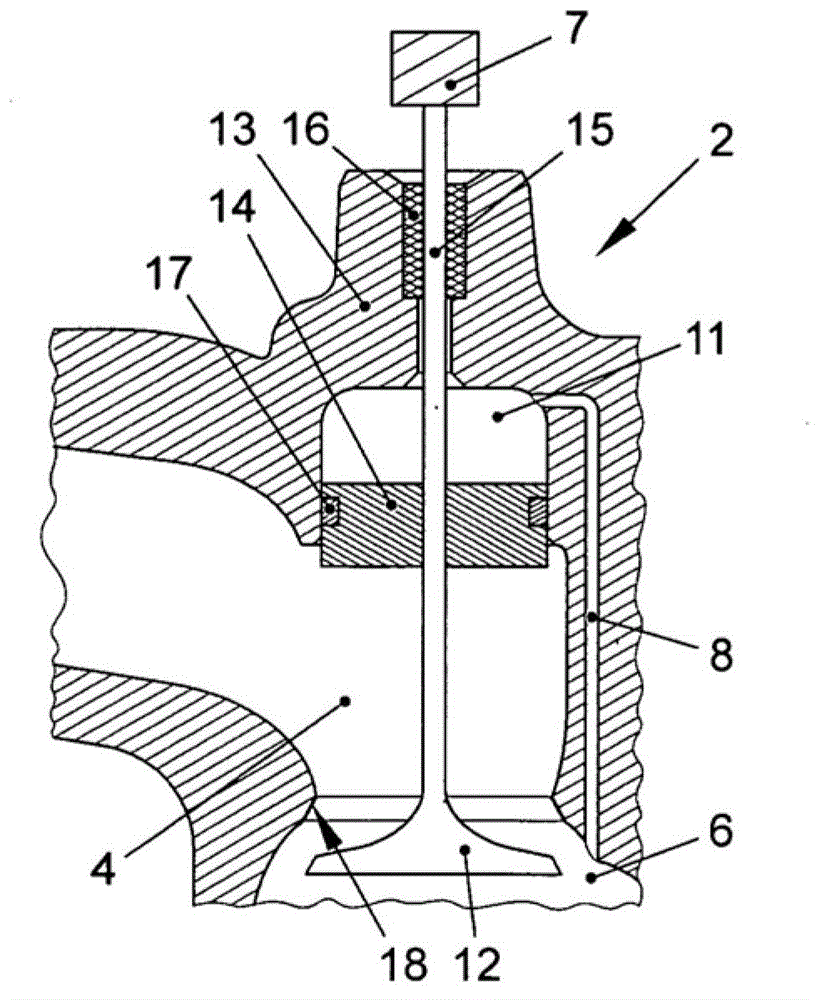

[0026] figure 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com