Low rolling resistance tyre for vehicles

A low rolling resistance, tire technology, applied in the direction of rolling resistance optimization, special tires, tire parts, etc., can solve the problems of high rolling resistance and high hysteresis value, and achieve the effect of low rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] (invention)

[0119] A. Preparation of tire tread radial outer layer

[0120] A rubber composition having the composition in Table I (parts in phr) was prepared by two-stage mixing at a fill factor of 70% using a known rotary mixer (such as a Banbury mixer) at In the first step, all ingredients except the vulcanization system were charged into a rotary mixer and mixed for 4 minutes at approximately 40 rpm.

[0121] When mixing, the mechanical work transferred to the mixture is controlled to keep the temperature inside the mixture at 150-155°C.

[0122] In the second step, when the rubber composition is cooled to 23°C, the vulcanization system is mixed with other ingredients in a rotary mixer at a speed of 20rpm for 4 minutes, and the temperature of the mixture is carefully kept at about 100°C to prevent overvulcanization. start early.

[0123] The following ingredients are used:

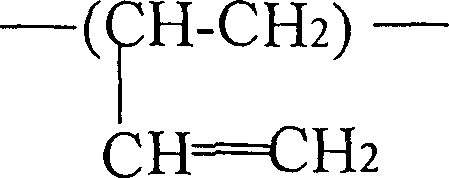

[0124] -S-SBR-A = end-capped and coupled butadiene-styrene copolymer, prepared in a so...

Embodiment 2

[0145] (invention)

[0146] According to the method described in Example 1, the rubber composition with the composition in Table I was prepared.

[0147] In addition to the ingredients used in the rubber composition of the radial inner layer described in Example 1, the following ingredients were used:

[0148] - Kevlar(R) size = short fibrillated aramid fibers dispersed in a natural rubber polymeric matrix (weight percent of fibers = 23%).

Embodiment 7-8

[0156] (comparative example)

[0157]According to the method described in US Pat. No. 4,319,619, two kinds of rubber compositions were prepared for the radial inner layer of the tire tread in comparison with Example 1 and Example 3 in the patent.

[0158] In addition to the components used in the rubber composition of the radial inner layer described in Example 1, the following ingredients were used:

[0159] -E-SBR1500=The commercial name on the market is EUROPRENE TM 1500 (Enichem Corporation) emulsion-based butadiene styrene copolymer.

[0160] The composition of this rubber composition is reported in Table II.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com