Weatherproof glass fiber reinforced PA66 high-speed rail sleeve material and preparation method thereof

A track sleeve and high-speed rail technology, which is applied in the field of weather-resistant glass fiber reinforced PA66 high-speed rail sleeve material and its preparation, can solve the problems of high-standard requirements and unsatisfactory strength of high-speed rail sleeve, and achieve excellent rheological processing and impact resistance. Good performance, good mechanical strength, long-term high temperature resistance and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

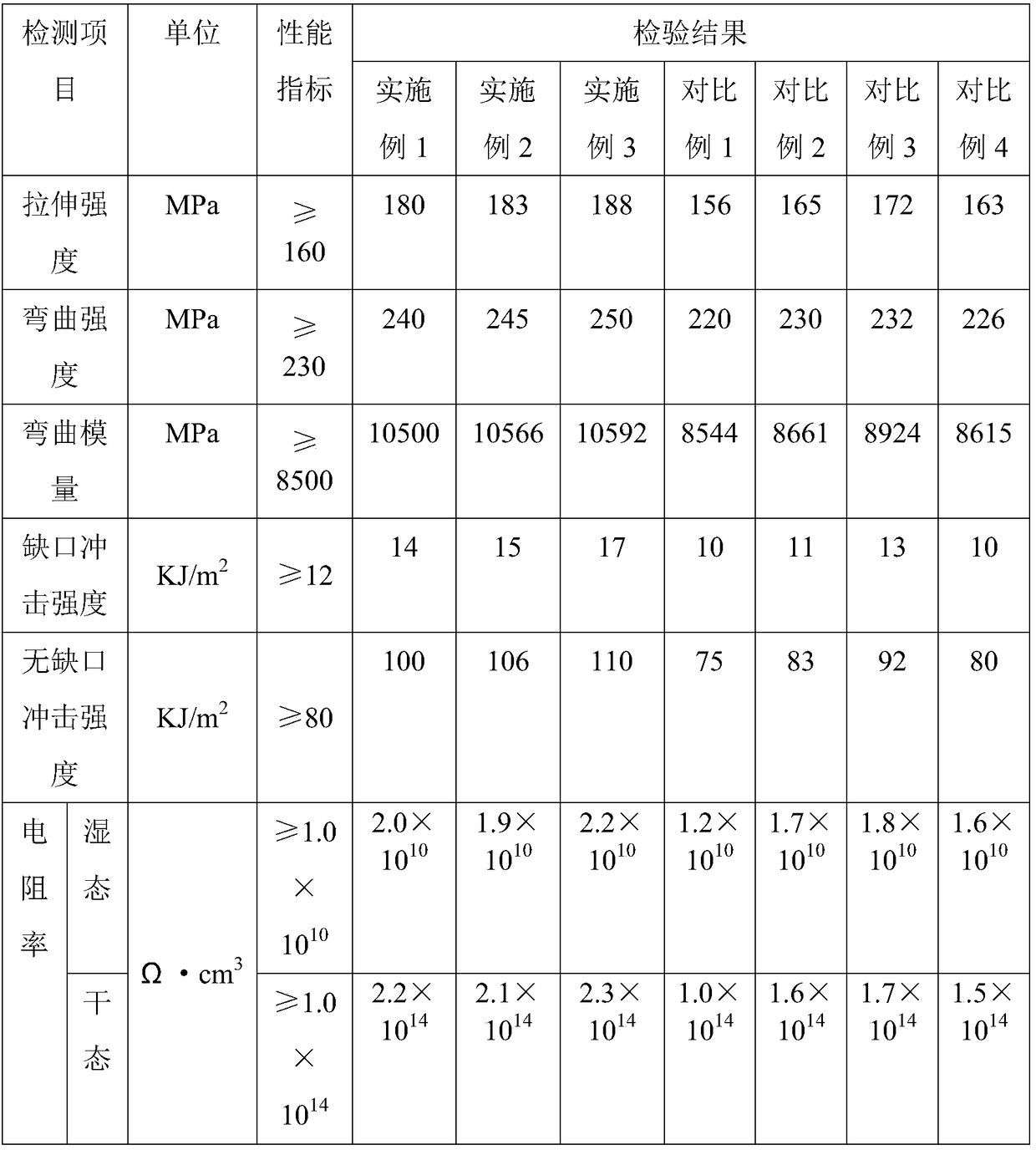

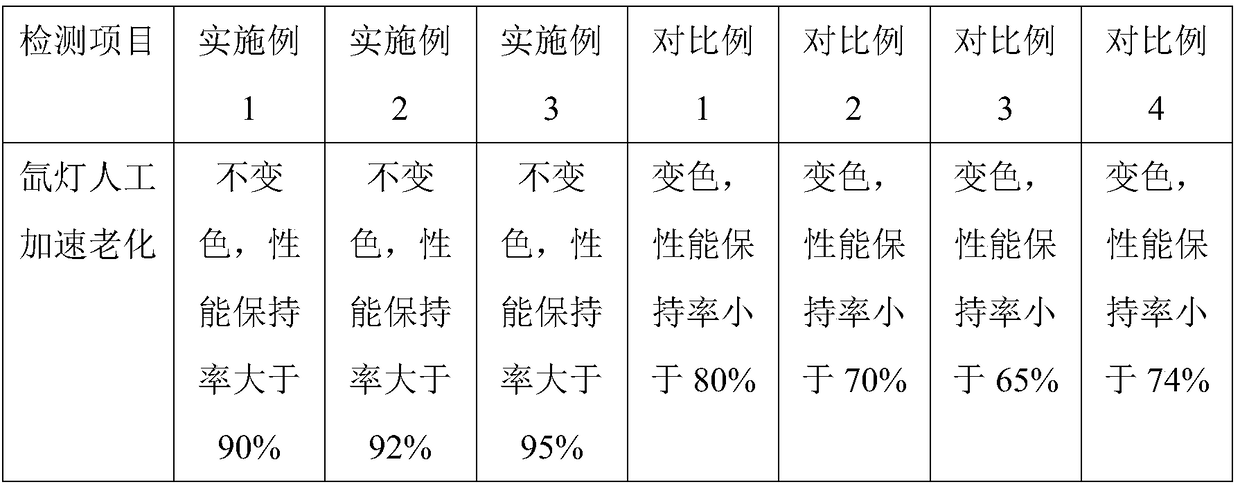

Examples

Embodiment 1

[0036] Embodiment 1, a weather-resistant glass fiber reinforced PA66 high-speed rail track sleeve material

[0037] The weather-resistant glass fiber reinforced PA66 high-speed rail track sleeve material consists of the following components and their weight percentages:

[0038] PA66 resin 44.0%, PA6T resin 10.0%, antioxidant 1010 0.5%, antioxidant 1098 0.5%, lubricant 0.5%, inorganic filler 10.0%, toughening agent 1%, weather resistance agent 0.5%, glass fiber 33% The lubricant is silicone; the inorganic filler is a particle size of 600 mesh glass beads; the toughening agent is a toughening agent POE; the weathering agent is 2'-(2'-hydroxyl-3' -tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole. Preparation:

[0039] S1 Mix antioxidant 1010, antioxidant 1098, lubricant, inorganic filler, toughening agent and weathering agent at a rotational speed of 500r / min for 3 minutes to obtain mixed material A;

[0040] S2 Add PA66 resin and PA6T resin to the mixed material A obtained ...

Embodiment 2

[0042] Embodiment 2, a weather-resistant glass fiber reinforced PA66 high-speed rail track sleeve material

[0043] The weather-resistant glass fiber reinforced PA66 high-speed rail track sleeve material consists of the following components and their weight percentages:

[0044] PA66 resin 58.3%, PA6T resin 5.0%, antioxidant 1010 0.3%, antioxidant 1098 0.3%, lubricant 0.3%, inorganic filler 5.0%, toughening agent 0.5%, weather resistance agent 0.3%, glass fiber 30% The lubricant is OP wax; the inorganic filler is a particle size of 3000 mesh glass beads; the toughening agent is a toughening agent POE; the weathering agent is 2-(2'-hydroxyl-3', 5'-di-tert-butylphenyl)-5-chlorobenzotriazole. Preparation:

[0045] S1 Mix antioxidant 1010, antioxidant 1098, lubricant, inorganic filler, toughening agent and weathering agent at a rotational speed of 700r / min for 7 minutes to obtain mixed material A;

[0046] S2 Add PA66 resin and PA6T resin to the mixed material A obtained in ste...

Embodiment 3

[0048] Embodiment 3, a weather-resistant glass fiber reinforced PA66 high-speed rail track sleeve material

[0049] The weather-resistant glass fiber reinforced PA66 high-speed rail track sleeve material consists of the following components and their weight percentages:

[0050] PA66 resin 50%, PA6T resin 8.2%, antioxidant 1010 0.4%, antioxidant 1098 0.5%, lubricant 0.4%, inorganic filler 7.5%, toughening agent 0.6%, weather resistance agent 0.4%, glass fiber 32% ; The lubricant is silicone; The inorganic filler is a particle size of 1200 mesh glass beads; The toughening agent is a toughening agent POE; Benzophenone.

[0051] Preparation:

[0052] S1 Mix antioxidant 1010, antioxidant 1098, lubricant, inorganic filler, toughening agent and weathering agent at a rotational speed of 600r / min for 5 minutes to obtain mixed material A;

[0053] S2 Add PA66 resin and PA6T resin to the mixed material A obtained in step S1, and mix for 5 minutes at a rotating speed of 900r / min to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com