Semiconductor device and making method thereof

A manufacturing method and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the situation that the tungsten film is left behind after polishing, insufficiently polished, and cannot be accurately detected as an adherent layer and other problems to achieve the effect of preventing excessive polishing and insufficient polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

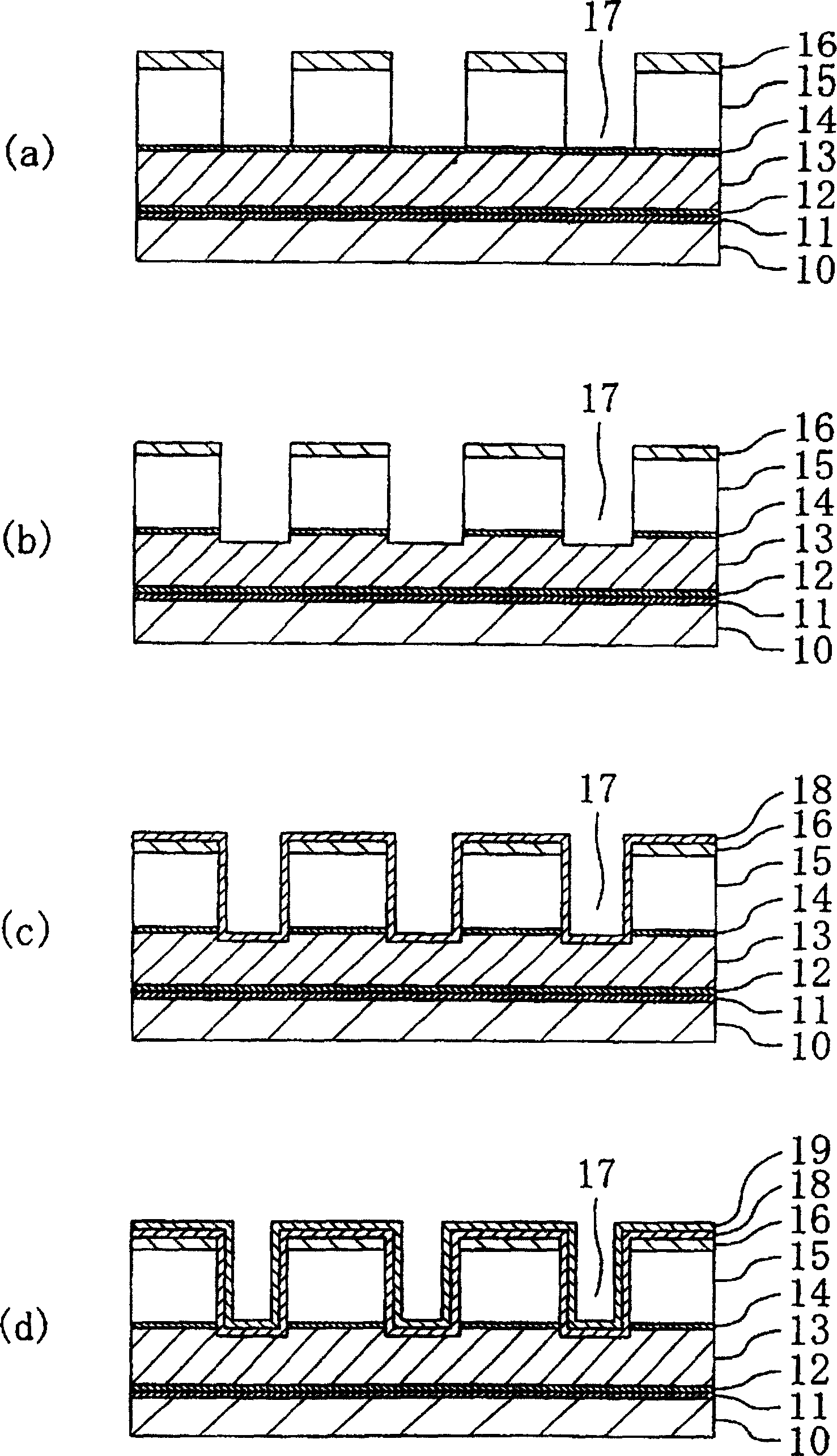

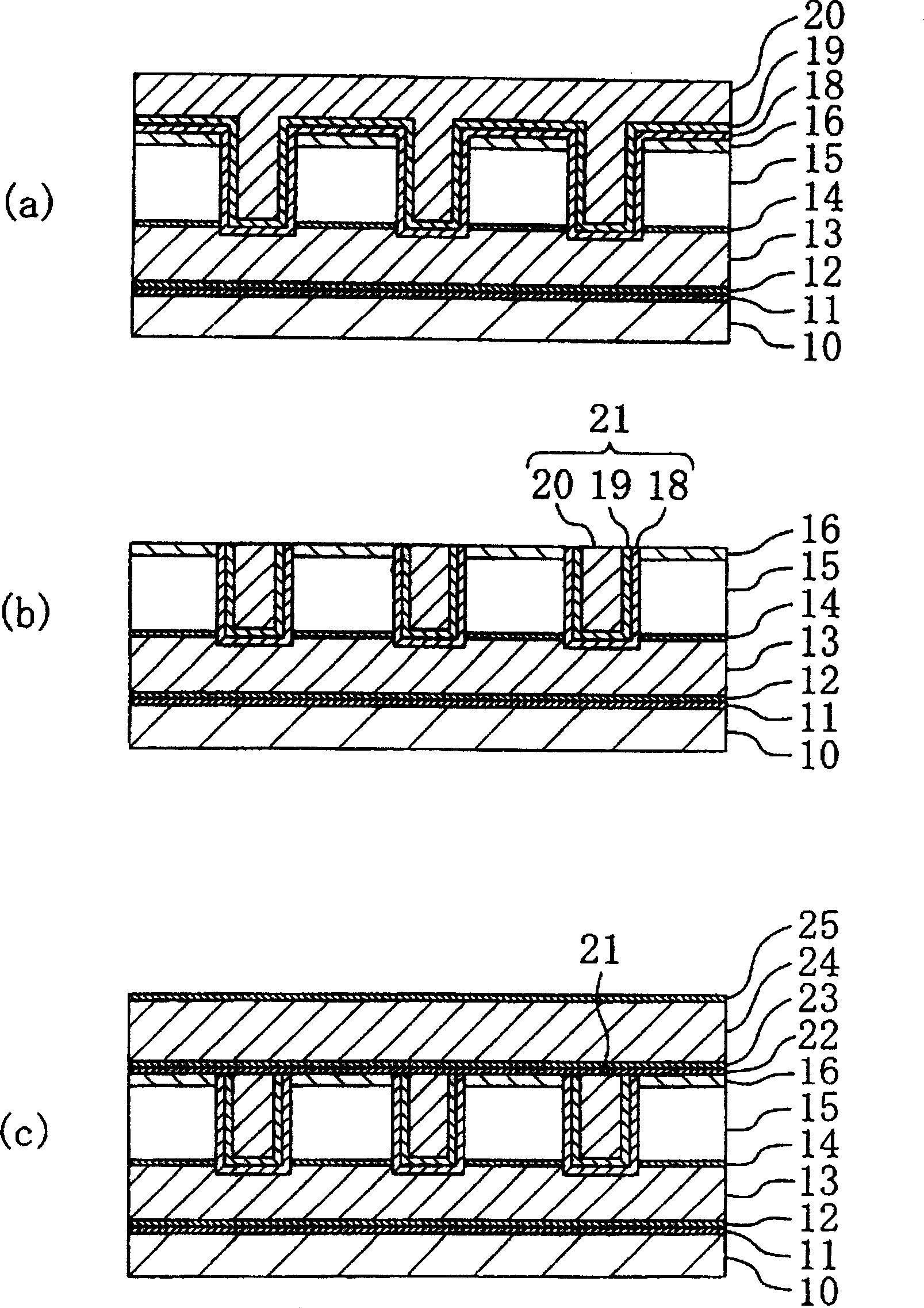

[0056] Below, refer to figure 1 (a)~(d) and figure 2 (a) to (c) The semiconductor device and its manufacturing method in Embodiment 1 of the present invention will be described.

[0057] First, if figure 1 As shown in (a), the lower layer metal wiring composed of the first titanium film 11, the first titanium nitride film 12, the first aluminum film 13 and the second titanium nitride film 14 is formed on the semiconductor substrate 10, and then A non-doped silicon oxide film (SiO 2 ) or an interlayer insulating film 15 made of a fluorine-doped silicon oxide film (SiOF).

[0058] Next, a silicon oxynitride film 16 as a hard film is formed on the interlayer insulating film 15 by plasma CVD, and then, the interlayer insulating film 15 is selectively etched using the silicon oxynitride film 16 as a mask. Etching is performed to form via holes 17 on the interlayer insulating film 15 . In addition, the first titanium film 11 and the first titanium nitride film 12 serve as an...

Embodiment 2

[0077] Below, refer to figure 1 (a)~(d) and figure 2 (a) to (c), the semiconductor device and the manufacturing method in Embodiment 2 of the present invention will be described.

[0078] Same as Example 1, such as figure 1 As shown in (a), on the semiconductor substrate 10, the lower layer metal wiring composed of the first titanium film 11, the first titanium nitride film 12, the first aluminum film 13 and the second titanium nitride film 14 is formed, and then, An interlayer insulating film 15 is formed over the entire semiconductor substrate 10 . Next, a silicon oxynitride film 16 is formed on the interlayer insulating film 15, and the interlayer insulating film 15 is selectively etched using the silicon oxynitride film as a film to form a via hole 17 in the interlayer insulating film 15.

[0079]Next, if figure 1 Shown in (b), silicon oxynitride film 16 is sputter-etched with argon element, improves the situation of the surface roughness of silicon oxynitride film...

Embodiment 3

[0096] Below, refer to figure 1 (a)~(d) and figure 2 (a) to (c) The semiconductor device and its manufacturing method according to Embodiment 3 of the present invention will be described.

[0097] Same as Example 1, such as figure 1 As shown in (a), the lower layer metal wiring composed of the first titanium film 11, the first titanium nitride film 12, the first aluminum film 13 and the second titanium nitride film 14 is formed on the semiconductor substrate 10, and then An interlayer insulating film 15 is formed over the entire semiconductor substrate 10 . Next, a silicon oxynitride film 16 is formed on the interlayer insulating film 15, and then, the interlayer insulating film 15 is selectively etched using the silicon oxynitride film 16 as a mask to form a via on the interlayer insulating film 15. Hole 17.

[0098] Next, if figure 1 Shown in (b), silicon oxynitride film 16 is sputter-etched with argon element, improves the rough condition of silicon oxynitride film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com