Negative ion paint additive

A technology of negative ion coatings and additives, applied in the coating and other directions, can solve the problems of high cost of photocatalytic materials and inappropriate use in large quantities, and achieve the effect of excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

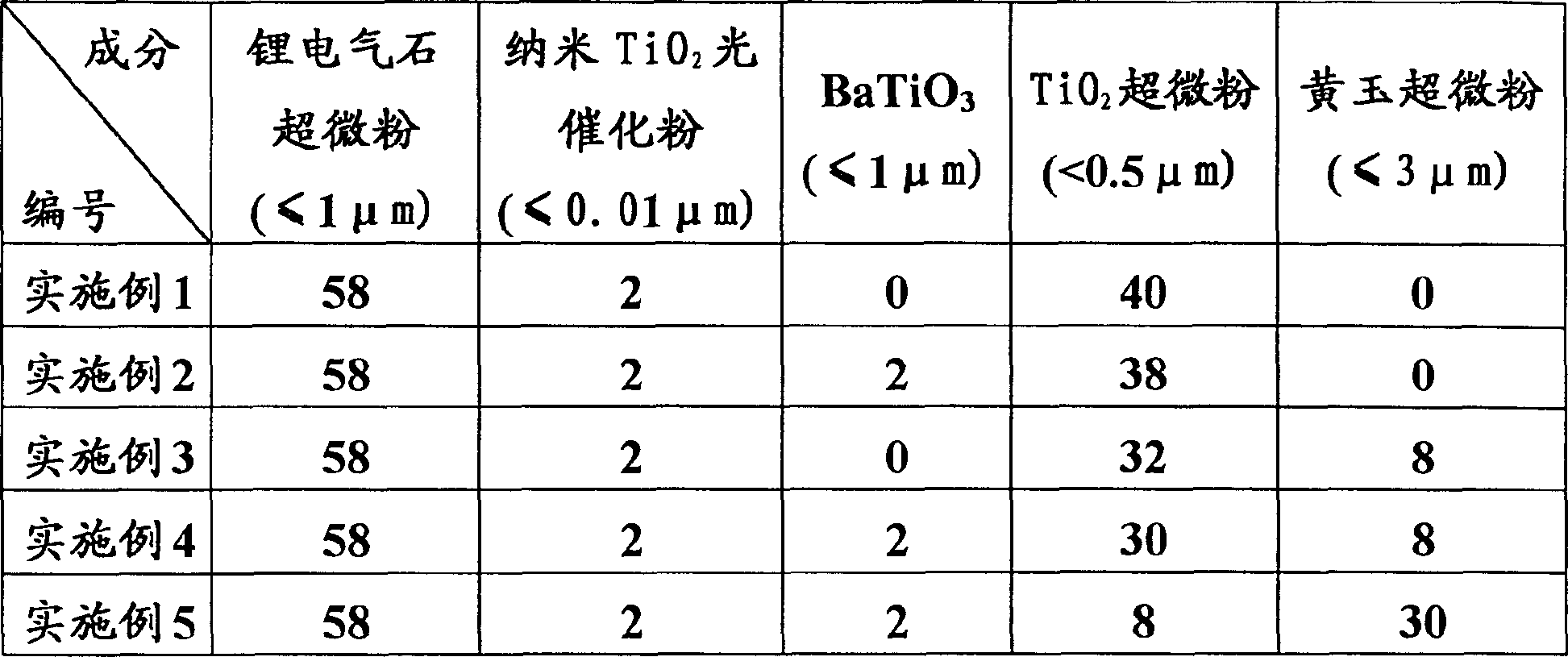

[0062] Lithium tourmaline was used in Examples 1-5, and ingredients were prepared according to the weight percentages of the ingredients listed in Table 1, and mixed well and evenly.

[0063] The composition ratio of table 1 embodiment 1-5

[0064]

[0065] Note: the data in the table is weight %

[0066] Then each 200g of the negative ion paint additive powder obtained in embodiment 1-5 is evenly spread out and placed in volume and is 0.5m 3 After 24 hours, use the 1C-1000 type air ion tester to measure the negative ion concentration in the tank under the conditions of room temperature 25° C. and relative humidity 55%, and the obtained results are listed in Table 2. It should be noted that in order to compare, the tourmaline in Examples 1-5 in Table 1 is divided into two types of electron beam treatment and no electron beam treatment. In the case of electron beam treatment, the used is the defocused electron beam, and the parameters during processing a...

Embodiment 6

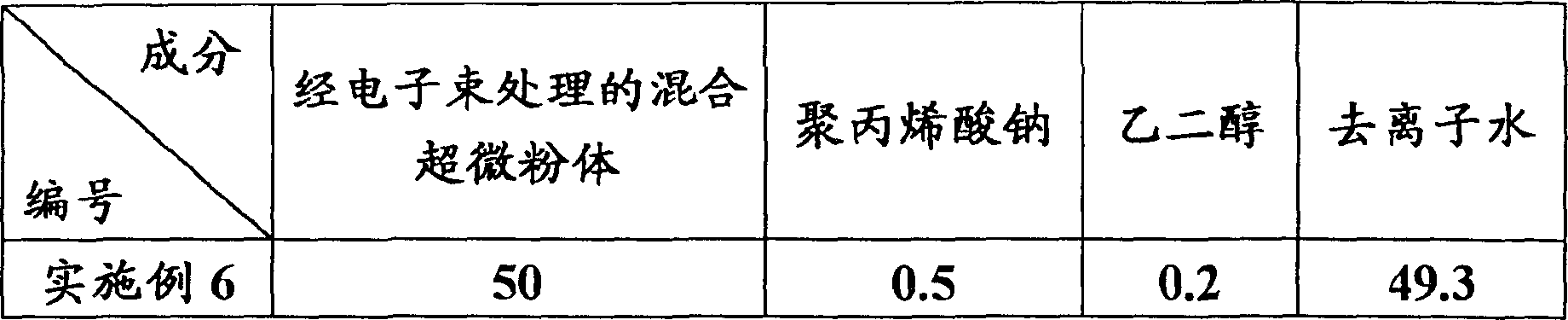

[0076] Using the mixed ultrafine powder of the above-mentioned embodiment 4, it is subjected to an electron beam activation strengthening treatment by using a defocused electron beam, and the treatment conditions are the same as those used in the above-mentioned embodiments 1-5. Then use the mixed ultrafine powder processed by the electron beam, cooperate with sodium polyacrylate (as anionic dispersant), ethylene glycol and deionized water in the ratio shown in Table 3, and obtain the negative ion coating additive slurry.

[0077] Table 3 Composition of negative ion coating additive slurry

[0078]

[0079] Note: the data in the table is weight %

[0080] Then, add 2% by weight of negative ion paint additive slurry of the present embodiment in a kind of Libang brand interior wall latex paint that buys on the market, make the paint film that size is 300 * 300mm (paint consumption is 150-160g paint / m 2 ) 6 pieces. In a simulation cabin with a volume of ...

Embodiment 7

[0083] Carry out the artificial poisoning of formaldehyde, ammonia and benzene vapor in advance in a simulation cabin of 200 liters, measure the content of these three kinds of gases contained therein, then add 6 pieces of coating membranes that contain negative ion additive identical with embodiment 6 , placed airtight for 48 hours and then measured the content of these three gases, based on which the removal rate of these three gases was obtained. The results obtained are shown in Table 4.

[0084] formaldehyde

[0085] As can be seen from the results of Table 4, the coating containing the negative ion coating additive of the present invention has a very high removal capacity to several common toxic gases (formaldehyde, ammonia, benzene) when usually carrying out indoor decoration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com