Method of concurrently burning aluminate, bauxite and aluminium sulfide gel material for generating boiler

An iron aluminate and power generation boiler technology, applied in the field of building materials, can solve the problems of short firing time, unfavorable clinker mineral formation, insufficient clinker formation time, etc., to simplify the production process, improve the sulfur fixation effect, and improve the product. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

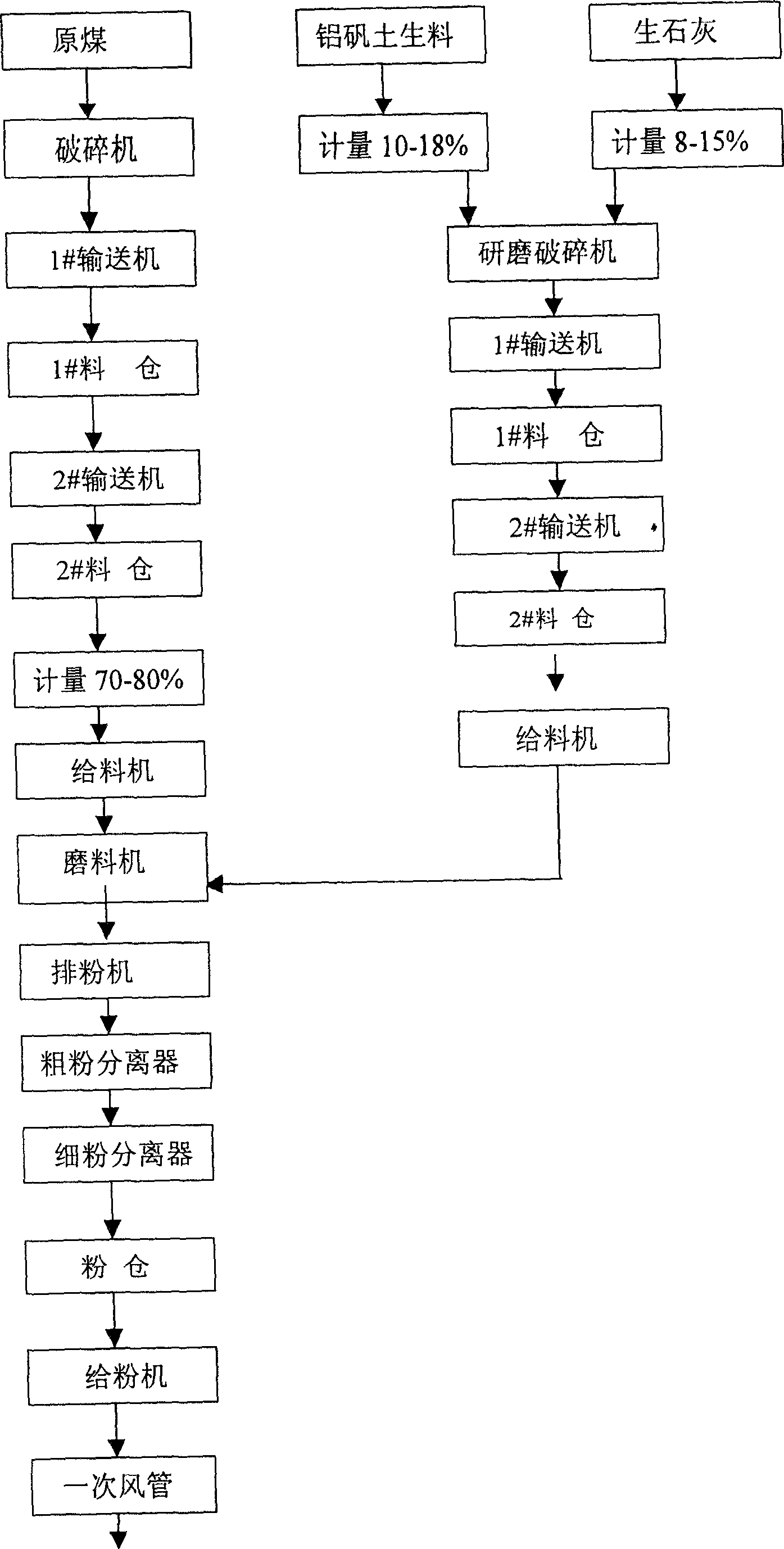

[0023] a. Raw coal (the ash content of coal is not higher than 35%) - sent to the crusher - via 1# conveyor - to 1# raw material warehouse - through 2# conveyor - to #2 raw material warehouse - Get raw coal (by weight) 70-80% into the feeder;

[0024] b. Take 10-18% of bauxite raw meal and 8-15% of quicklime through automatic metering device (by weight ratio)—send it to the grinding crusher—via 1# conveyor—to 1# raw material bin—pass 2# conveyor - to #2 raw material bin - enters the feeder;

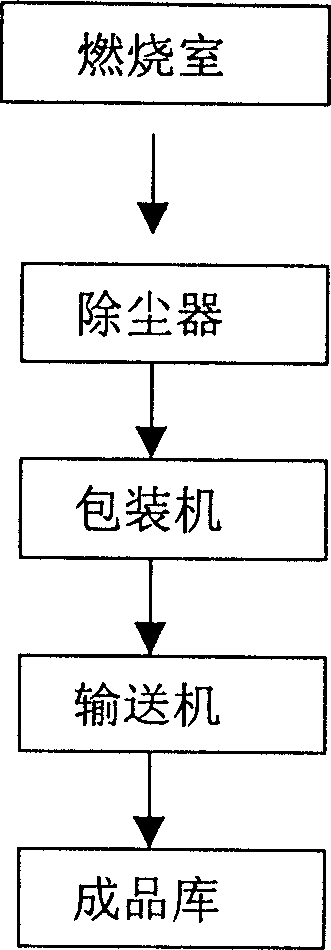

[0025] c. Send a and b to the grinding machine through the feeder—powder discharge fan—coarse powder separator—fine powder separator—to the coal powder bin—through the powder feeder—powder falling Pipe—Enter the primary air duct—carried into the furnace by the primary air—after burning, the ash particles pass through the electrostatic precipitator—packaging machine—conveyor—finally to the finished product warehouse.

[0026] The above process should be carried out under the condition th...

Embodiment 2

[0028] Take 70-80% of raw coal (the ash content of coal is not higher than 35%), 10-18% of bauxite raw meal, and 8-15% of quicklime through an automatic metering device (by weight)—feed into the crusher—through 1 #Conveyor - to 1# raw material bin - through 2# conveyor - to 2# raw material bin - into the feeder - into the existing coal mill - powder exhaust fan - coarse powder separator ——fine powder separator——to coal powder bin——through powder feeder——powder falling pipe——into the primary air duct——carried into the furnace by the primary air——after combustion, the ash particles pass through the electrostatic precipitator——package Machine - Conveyor - Finally to the finished product warehouse.

[0029] The above process should be carried out under the condition that the load is not lower than 70%. This embodiment makes full use of the existing technological process of the power plant, and saves a set of grinding and conveying system compared with Embodiment 1, saving one-tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com