Thermal-response switch

A thermal response and switching technology, which is applied to thermal switches, electrical switches, thermal switch components, etc., can solve the problem that the bimetal suction fixture 51 and the laser irradiation device 52 cannot be arranged in the same position, and the position of the bimetal strip is offset. It can solve the problems of shifting, can not be manufactured cheaply, etc., to achieve the effect of simple assembly process, stable welding depth, and stable joint strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below, the embodiment of the present invention is described with reference to accompanying drawing,

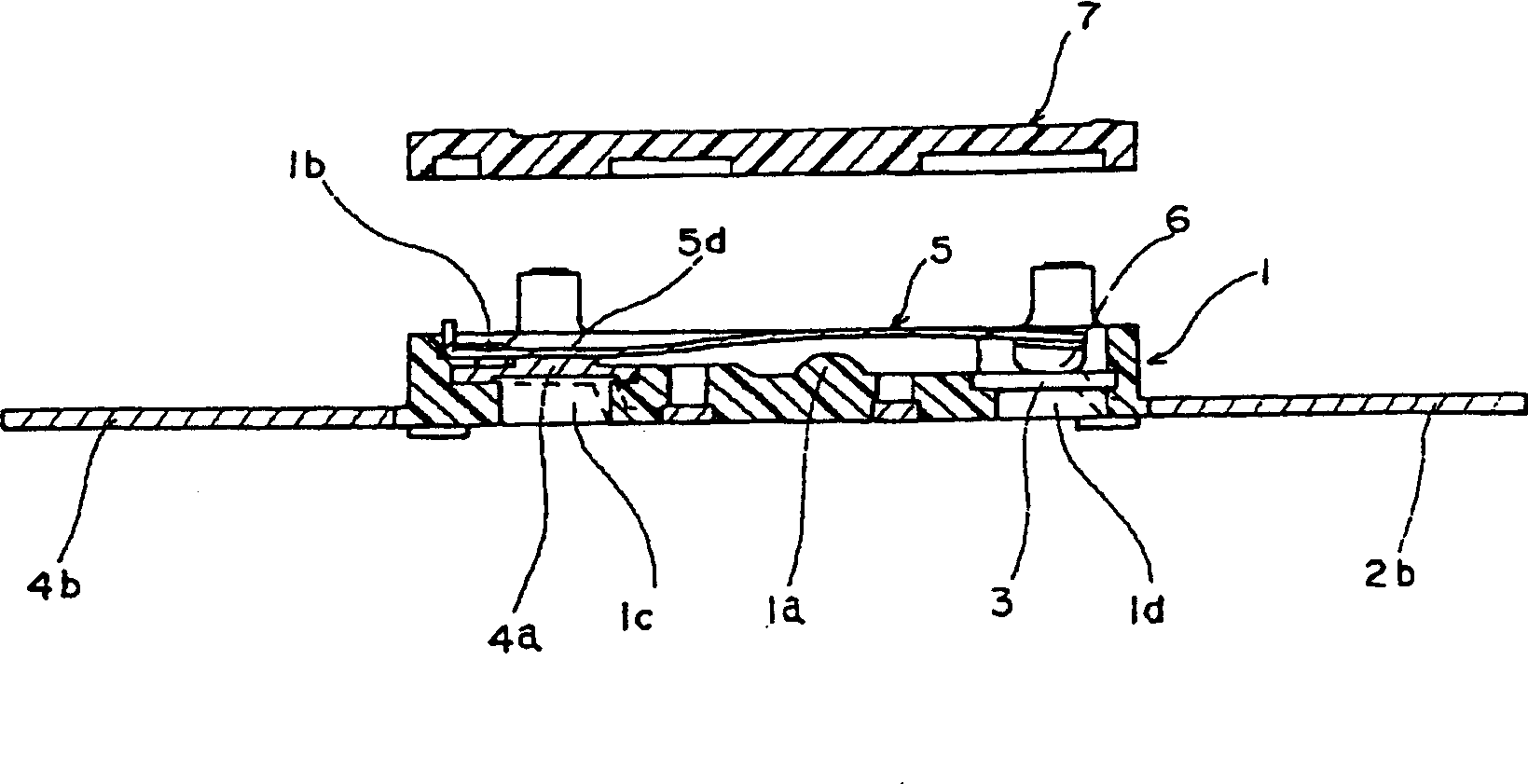

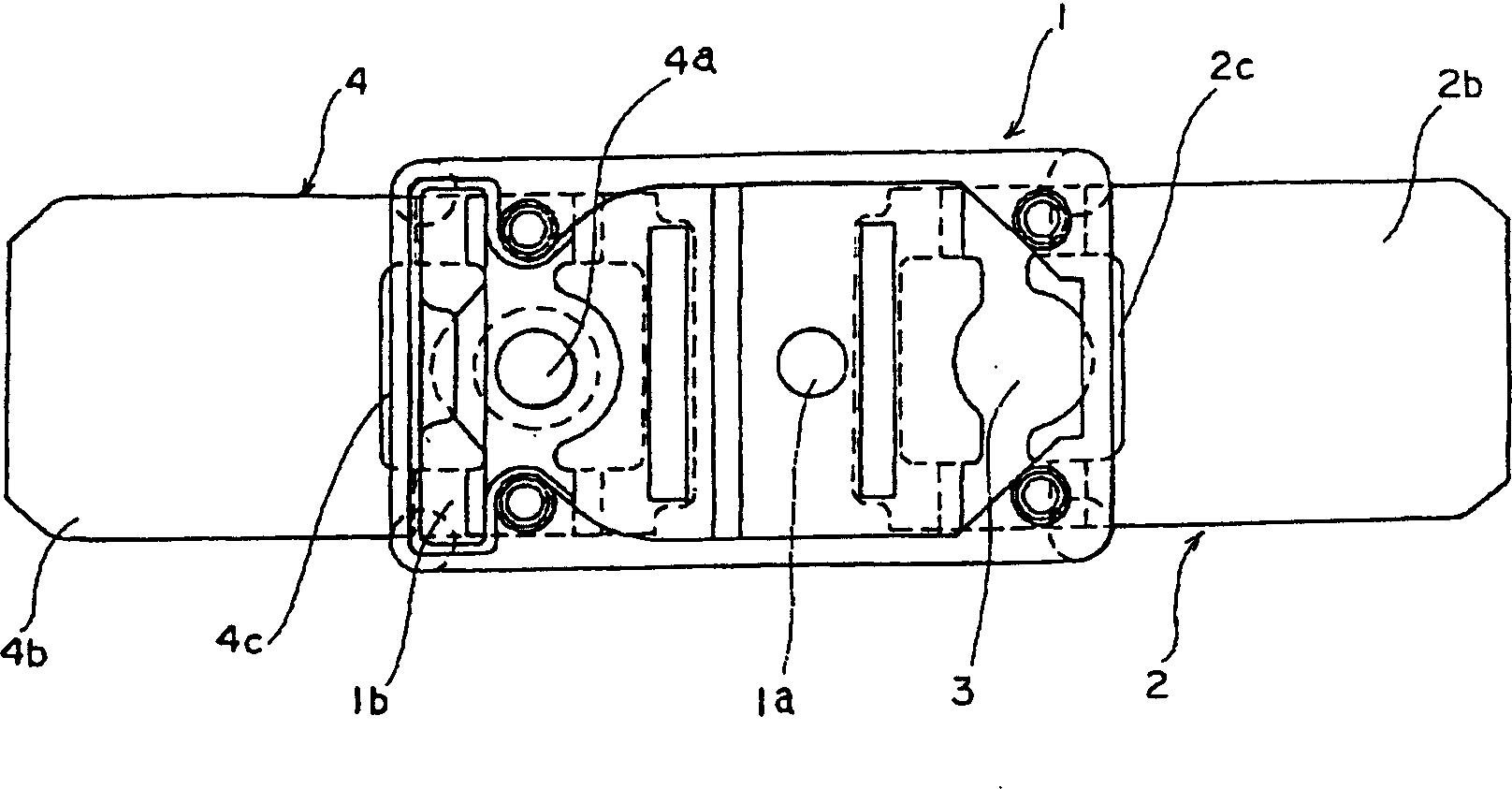

[0035] under, Figure 1 to Figure 9 Examples of the present invention are shown. figure 1 It is a top view with the thermal response switch cover removed. figure 2 yes means figure 1 A cross-sectional view of the thermally reactive switch shown with the cover removed. image 3 yes means figure 1 A top view of the housing with the fixed contacts and fixed terminals of the thermally reactive switch shown with the cover removed. Figure 4 yes means figure 1 It is a sectional view of the housing with the fixed contacts and the fixed terminals in the state where the cover is removed of the shown thermal response switch. Figure 5 yes means figure 1 The bottom view of the housing with the fixed contacts and fixed terminals of the shown thermal response switch with the cover removed. Image 6 yes means figure 1 Top view of the bimetal strip with the movable con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com