Screw joint for oil pipe or casing

A technology of threaded joints and casings, which is applied in the field of threaded joints, casing threaded joints, and oil fields. It can solve the problems of low API thread connection strength, reduce thread peak stress, and poor stress corrosion resistance, so as to improve connection strength and anti-corrosion. Capability of stress corrosion, reduction of peak stress, effects of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

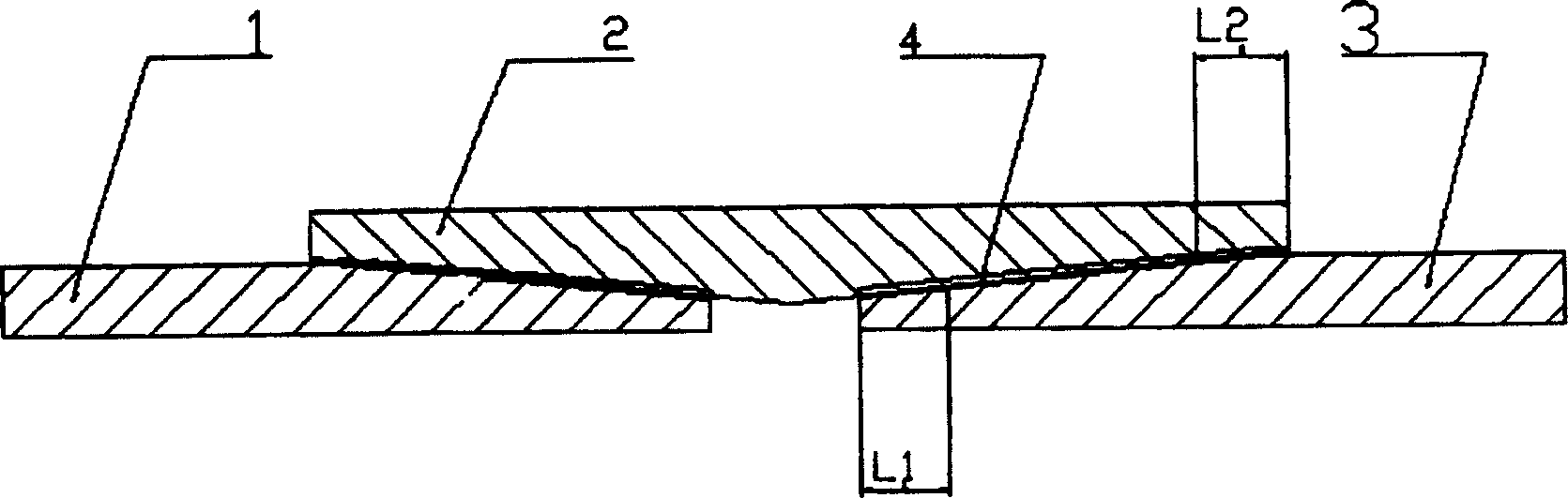

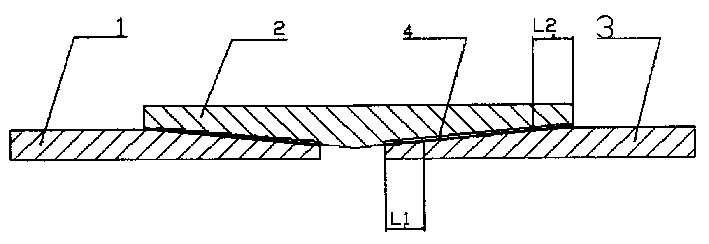

[0019] The present invention is used in the case of partial trapezoidal thread, which consists of pipe body 1, 3 and pipe coupling 2 screwed together by partial trapezoidal thread 4. The taper of the thread is 1:16, the thread height is 1.575mm, and the pitch is ( 25.4mm) 5 teeth, that is 5.08mm. The size of the pipe body is Φ139.7×7.72mm, the outer diameter of the coupling W=153.7mm, and the thickness of the big end face=5.21mm. The length of the engaging thread is 97.155mm, and there are 19 teeth in total. Material properties σs=552Mpa, E=2.1×10 5 MPa. After calculation, choose the variable pitch of 3 threads at both ends of the external thread, m x =0.014mm, m y=0.016mm, the pitch of the middle part of the external thread is 5.08mm, the pitch of the three teeth at the far right is 5.08-0.016=5.064mm, and the pitch of the three teeth at the leftmost end is 5.08+0.014=5.094mm, the axial clearance t3'= formed at this time 0.048mm, t3=0.042mm, t2'=0.032mm, t2=0.028mm, t1'=...

Embodiment 2

[0021] When the present invention is used for round threads, the thread taper is 1:16, the height is 1.810mm, and the thread pitch is 8 teeth per inch (25.4mm), that is, 3.175mm. The size of the pipe body is Φ139.7×7.72mm, the outer diameter of the coupling W=153.7mm, and the thickness of the big end face=5.79mm. Engaging thread length is 81.661mm, 26 teeth in total. Material properties σs=552Mpa, E=2.1×10 5 MPa. After calculation choose P 前 =P 后 =3.175+0.015=3.190mm, 3 threads at both ends of the external thread and then turned. After this treatment, the peak stress at both ends of the thread dropped by more than 1 / 3.

Embodiment 3

[0023] The present invention is used in the case of a cylindrical thread, the thread is a cylindrical thread, the tooth height is 1.575mm, and the pitch is 5.08mm. The outer diameter of the pipe is 140mm, the wall thickness is 10mm, the outer diameter of the coupling is 160.3mm, the wall thickness is 8.565mm, the length of the engaging thread is 45.72mm, and there are 9 teeth in total. Material properties σs=552Mpa, E=2.1×10 5 MPa. After calculation, choose 2 thread variable pitches at both ends of the external thread, m x = m y = 0.009mm, the pitch of the middle part of the external thread is 5.08mm, the pitch of the 2 threads at the far right is 5.08-0.009 = 5.071mm, the pitch of the 2 threads at the far left is 5.08+0.009=5.089mm, the axial gap formed at this time is at the extreme ends The second tooth is t1=0.018mm and the second inner tooth t2=0.009mm. After this treatment, the peak stress at both ends of the thread dropped by nearly 1 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com