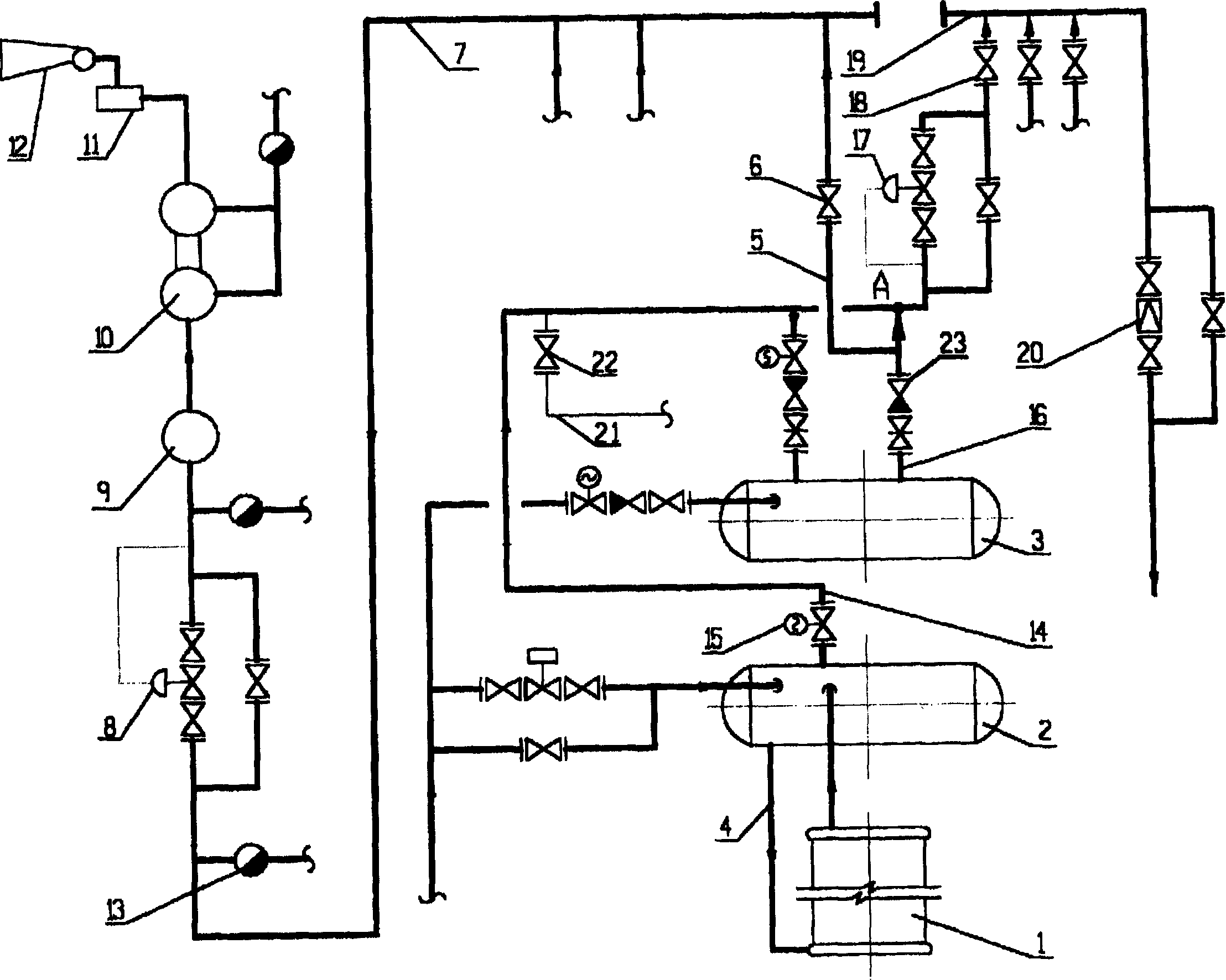

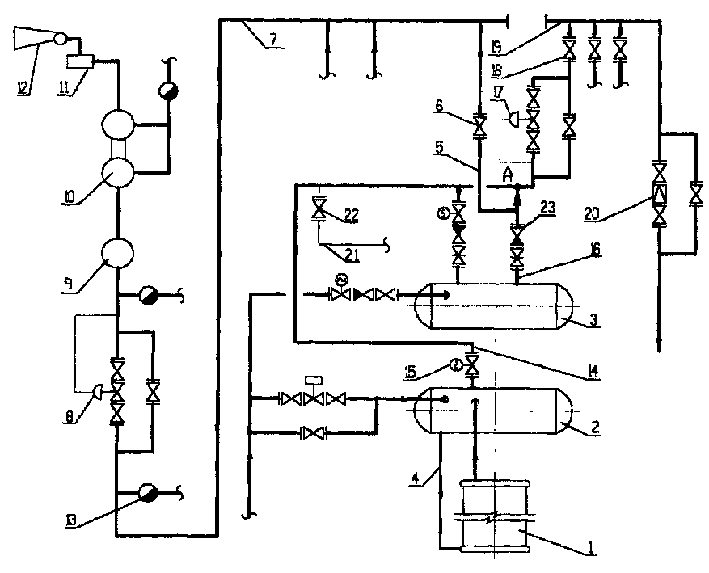

Plant for using converter produced vapor in vacuum refining furnace

A vacuum refining furnace and converter technology, applied in furnaces, furnace components, steam generation, etc., can solve the problems of poor quality and difficulty of self-produced steam for converter vaporization cooling, lack of converter vaporization cooling system, etc., and improve unit heat storage The effect of capacity, fast return on investment, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0036] Example: Process Parameters of Converter Evaporative Cooling System for Vacuum Pump Supply

[0037] name

[0038] Vacuum pump steam system and requirements:

[0039] 1) The smelting cycle of the vacuum refining furnace is 40 minutes, and the steam consumption time is 20-25 minutes.

[0040] 2) The maximum variation of the steam consumption is 10.5t / h. During the steam supply period, the steam supply pressure must be stable, and the steam pressure fluctuation must be stabilized within 5 seconds.

[0041] device name

[0042] device name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com