Catalyst for producing vinyl acetate

A catalyst, acetic acid technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as reduction and achieve large Bulk porosity, high space-time yield, and effects of pressure drop loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

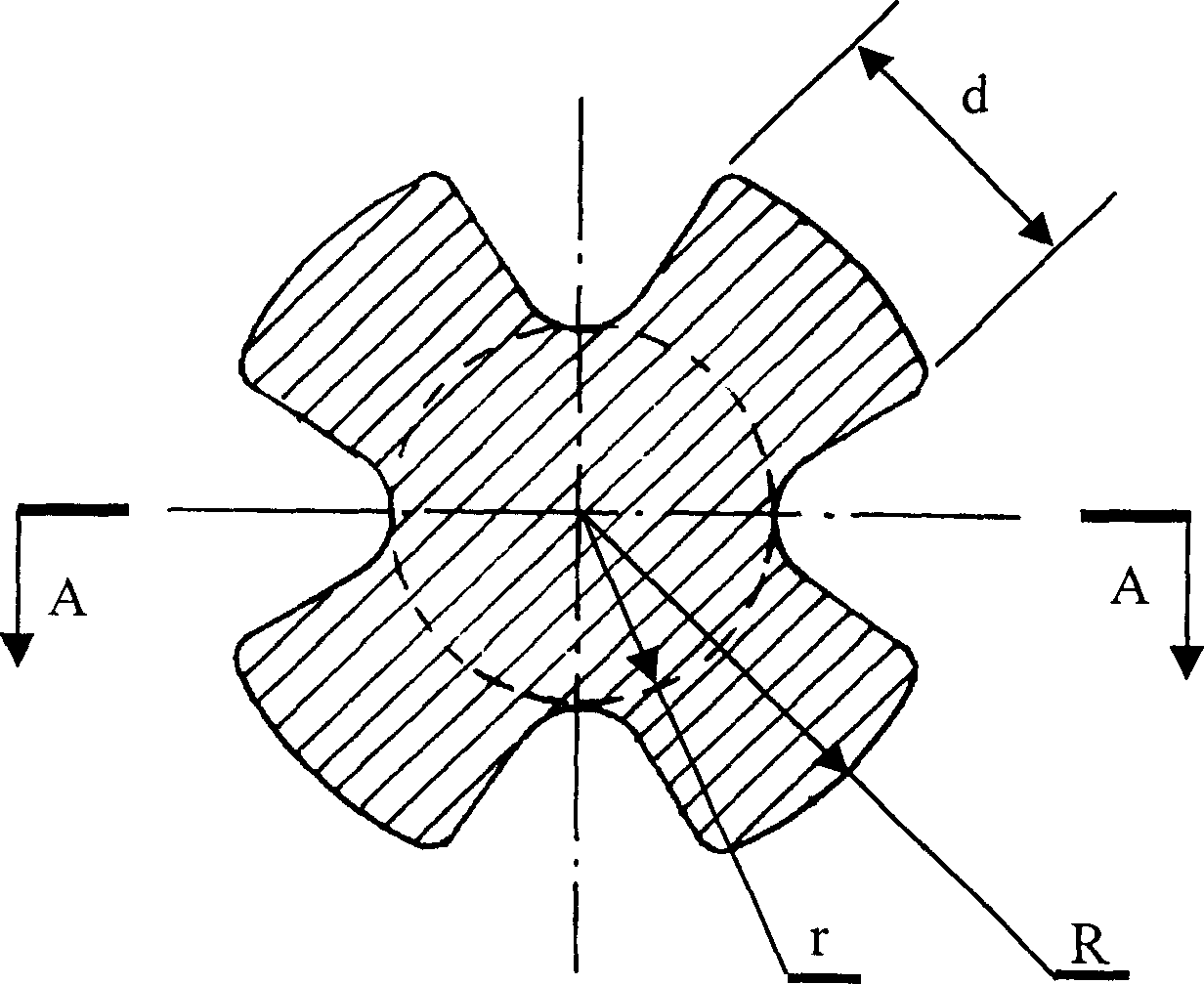

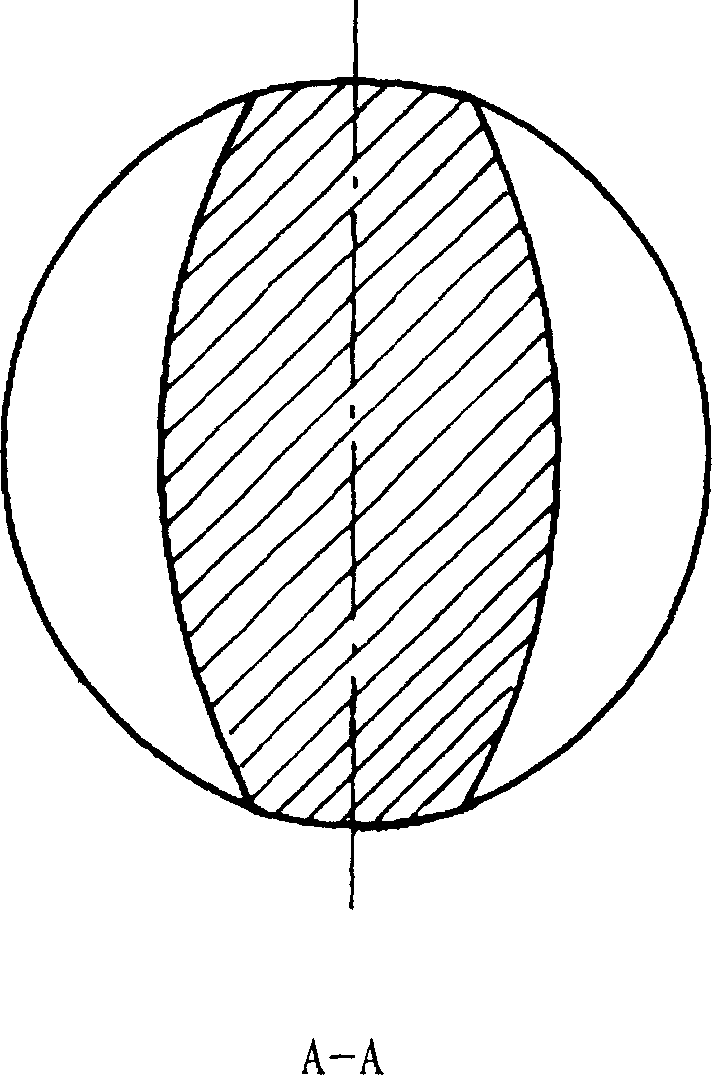

Method used

Image

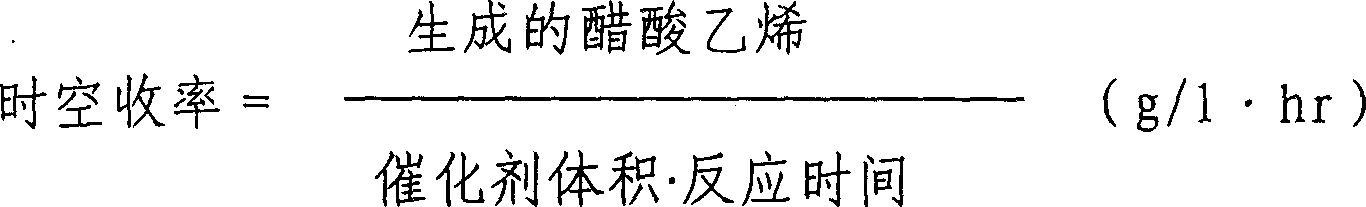

Examples

Embodiment 1~6

[0026] Vector preparation:

[0027] Add extrusion aids and binders to the silica gel powder, mix well, and form the carrier precursor by extrusion. Dry the carrier at room temperature for 48 hours, then dry it at 100°C for 24 hours, and place it in a muffle furnace for 730 °C for 2 hours. After cooling, put it into an autoclave, add a solution made of acetic acid and ammonium acetate, take out the carrier at 165°C and 0.6MPa for 14 hours at constant temperature and pressure, wash it with distilled water until it is neutral, and then roast it at 300°C for 3 hours. After cooling, the desired carrier is obtained. The physical characteristics of the carriers prepared in each embodiment are shown in Table 1.

[0028] Catalyst preparation:

[0029] With Na containing the equivalent of 6.35 g palladium 2 PdCl 4 and HAuCl equivalent to 2.96 g of gold 4 Prepare 450ml of aqueous solution, take 1.1 liters of the carrier obtained above and soak it for a while, dry it slightly, put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com