Catalyst for ethylene process of preparing vinyl acetate

A catalyst, acetic acid technology, applied in the direction of physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of long residence time, aggravation, Catalyst selectivity decline and other problems, to achieve the effects of low bed pressure drop loss, high space-time yield, and excellent selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0033] First in SiO 2 Add binder magnesium stearate to make microspheres, then add organic filler and lubricant, and shape by extrusion. The carrier particle blank is then calcined at a temperature of 750°C and in an oxygen-containing atmosphere for 3 hours, and the specific surface area of the prepared carrier is 160-200m 2 / g, the pore volume is 0.7-0.9ml / g.

[0034] With Na containing the equivalent of 3.69 grams of palladium 2 PdCl 4 and HAuCl equivalent to 1.71 g of gold 4 Prepare 450ml of aqueous solution, then take 1.1 liters of the above-mentioned carrier and soak it for a while, take out the carrier and dry it to a moisture content of 98%, then place the carrier in 540ml containing 275 grams of Na 2 SiO 3 .9H 2 O solution, let it stand at room temperature for 12 hours, and then measure the pH value of the solution to be 7.9. After adding 25ml of 85% (w.t.) hydrazine hydrate and standing for 4 hours, the palladium and gold compounds loaded on the carrier were ...

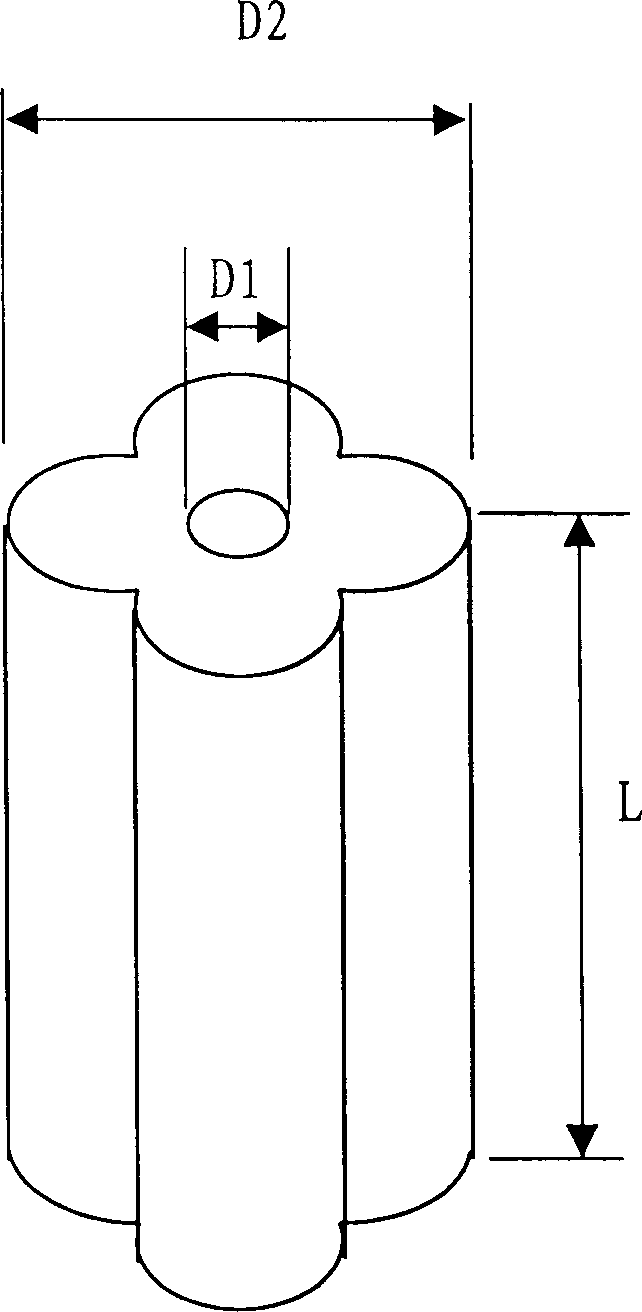

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com