Making process of antireflecting protection component for projecting screen

A technology for projection screens and manufacturing methods, which is applied to optics, instruments, projection devices, etc., can solve the problems of affecting image quality, low production efficiency, and no reduction in reflectivity, and achieve simple production process, high production efficiency, and thickness. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

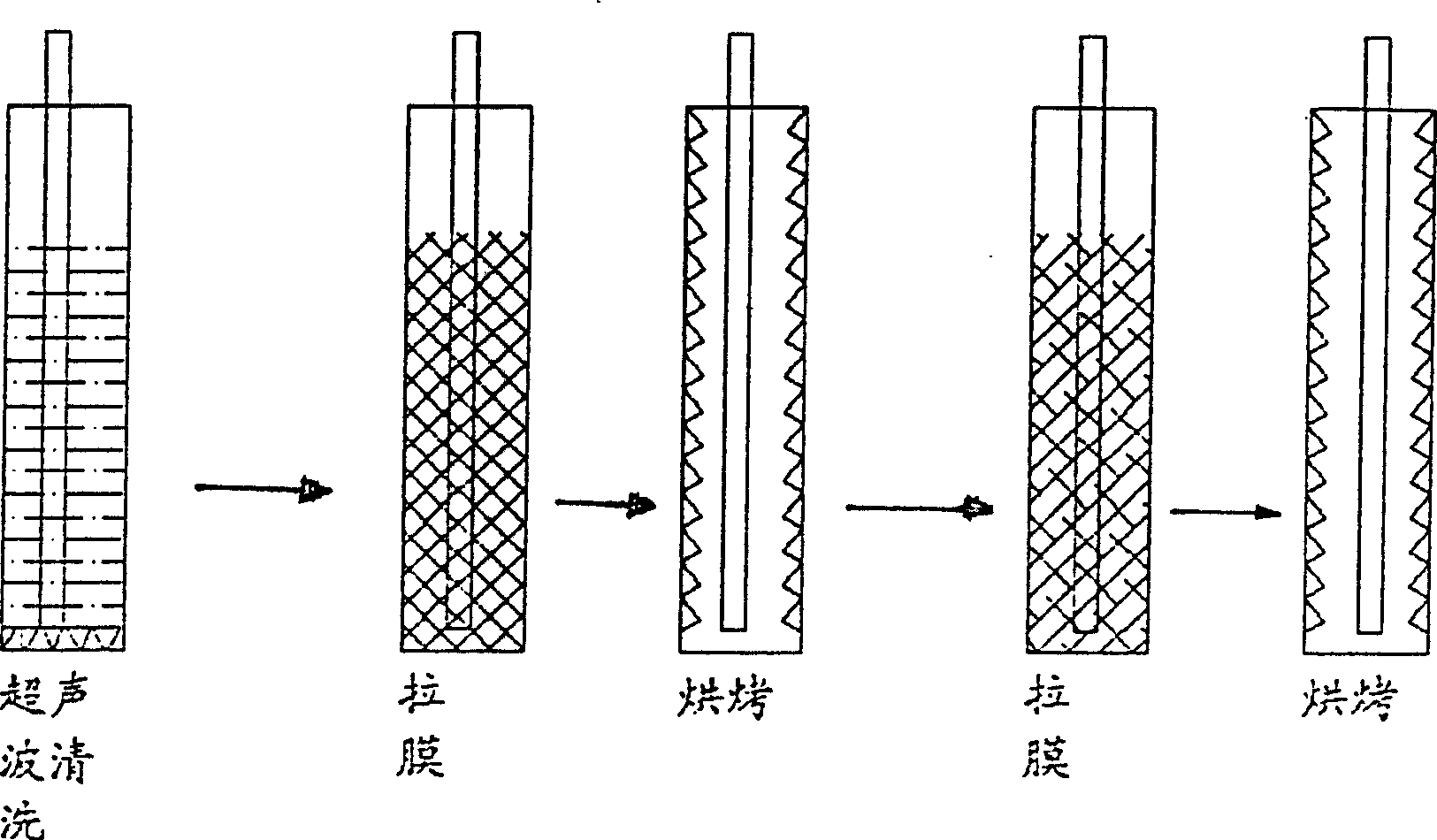

[0032] The present invention is shown in a diagram, which describes the equipment and process for continuously producing anti-reflection and anti-reflection protection components, that is, anti-reflection and anti-reflection glass. Its production process is as follows:

[0033] The first step: glass cleaning, considering the large area of the glass, it is generally cleaned by ultrasonic cleaning process. Glass uses K 9 tempered glass.

[0034] The second step: place the above-mentioned cleaned glass on Ti(OC 2 h 5 ) 4 +4H 2 O solution pulls the film, forming H on the double surface of the glass 4 TiO 4 +C 2 h 5 OH sol films. Control the stable environmental conditions. The liquid temperature is 25° C. to 36° C., and the drawing speed is controlled at 0.1 to 0.5 m / s, so that the corresponding film thickness can be obtained.

[0035] Step 3: Bake in a constant temperature room at 110 to 150°C for 5 to 10 minutes to volatilize the dehydrated ethanol of titanate to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com