Variable compression ratio and variable air distributing phase

A technology of gas distribution phase and compression ratio, applied in electrical control, fuel injection control, engine control and other directions, can solve the problems of unstable automatic speed control of automobiles, increase equipment, manual operation, etc., to achieve no mechanical wear and reduce starting resistance. , the effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

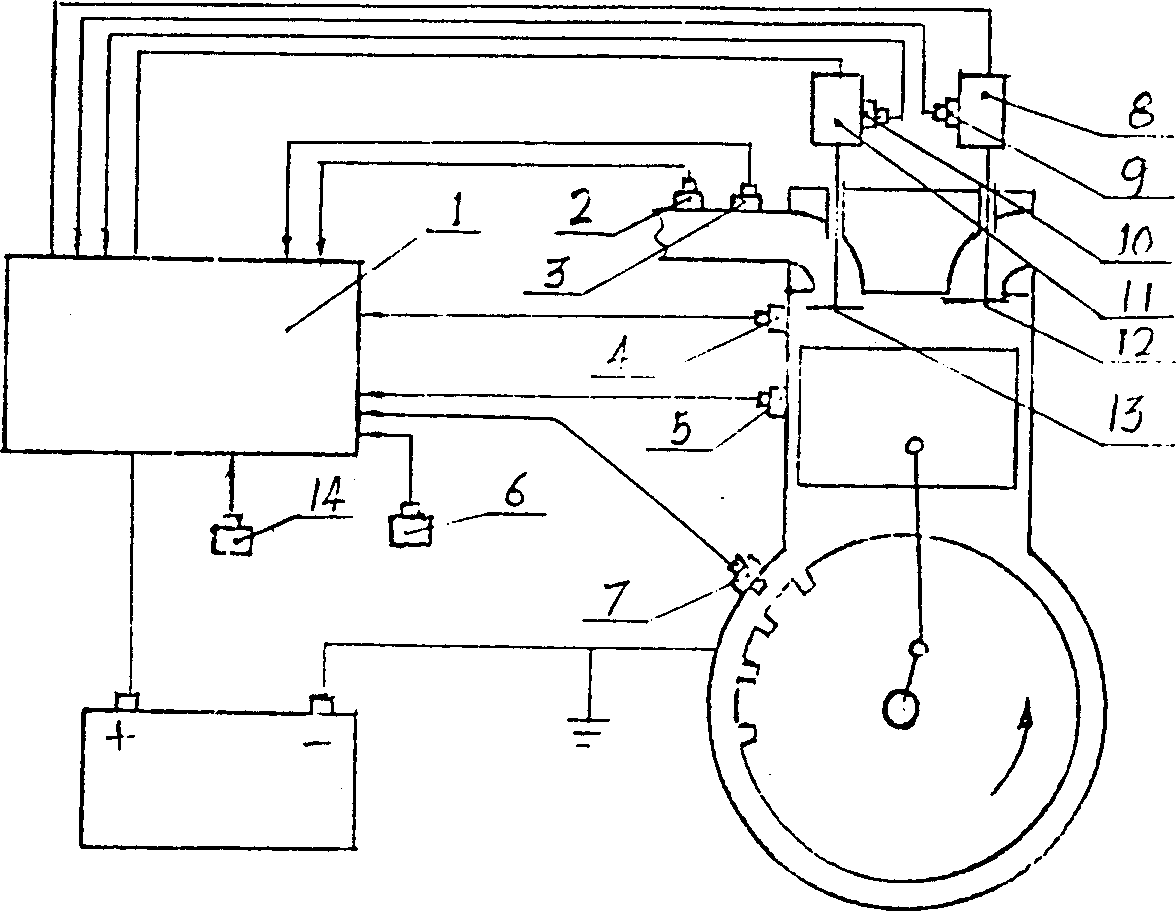

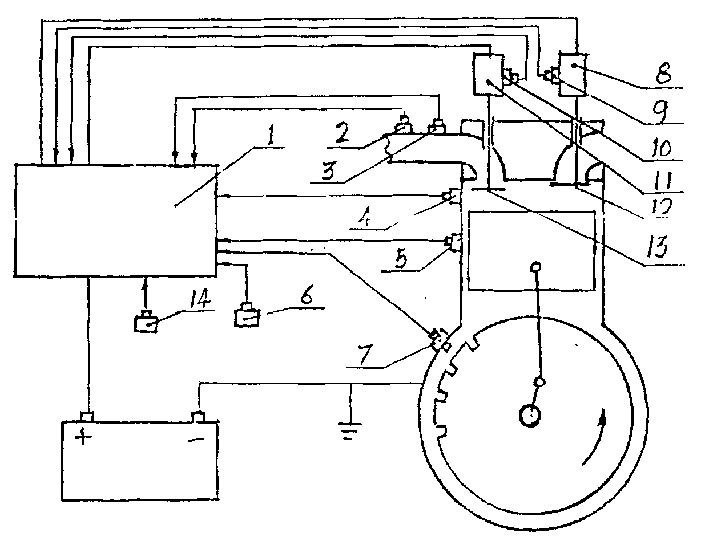

[0022] figure 1 It is a schematic diagram of variable variable compression ratio and variable valve timing of the present invention: while the engine is working, the microcomputer 1 controls various control data of the stable speed or load of the engine according to the acceleration position sensor 14; various command control data; engine Speed and crankshaft position sensor 7 measures data of engine speed, top dead center position and crankshaft angle; intake pipe pressure sensor 3 measures data of air pressure, and air flow sensor can also be used; air temperature sensor 2 measures data of intake air temperature; cooling water The temperature sensor 5 measures the data of the cooling temperature of the engine; the knock sensor 4 measures the data of whether knocking occurs; the altitude sensor 6 measures the data of the air density in the area; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com