EBSD sample preparation method for surface layer of metal material

A metal material, surface layer technology, applied in the direction of analyzing materials, using wave/particle radiation for material analysis, instruments, etc., can solve the problems of scratches or wear marks in the surface area that are difficult to eliminate, disadvantageous, surface stress, and deformation are difficult to remove, etc. Achieve smooth surface polishing effect and uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] This embodiment provides an EBSD sample preparation method for the surface layer of a metal material, comprising the following steps:

[0023] 1) Sample preparation: use a wire cutting machine to intercept the surface area of the sample to be analyzed, prepare the sample and clean it;

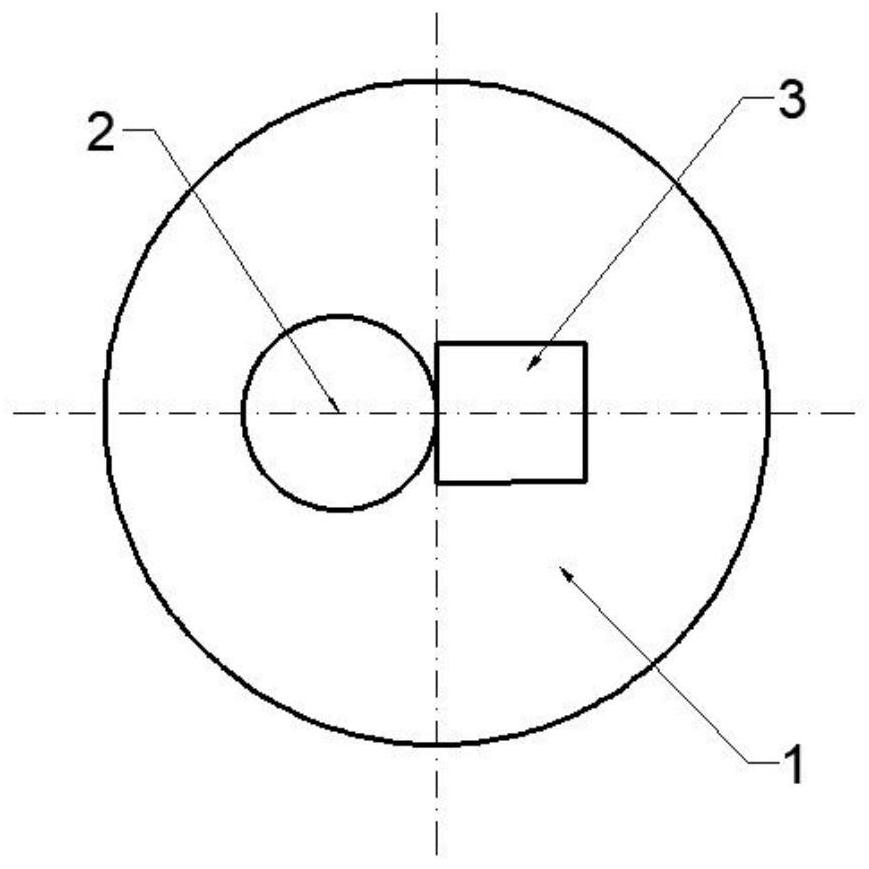

[0024] 2) Mounting: This step is very important, and the sample prepared in step (1) is mounted in the center of the resin;

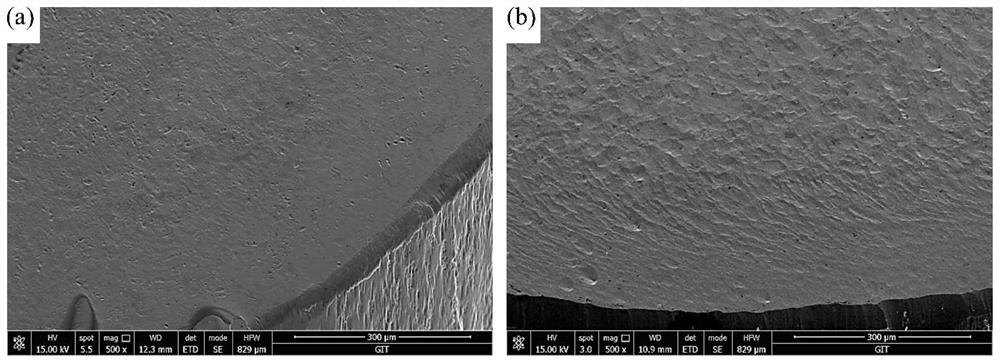

[0025] 3) Polishing: rough polishing the sample in step (2) with silicon carbide water sandpaper, and then fine polishing with nano-polishing liquid;

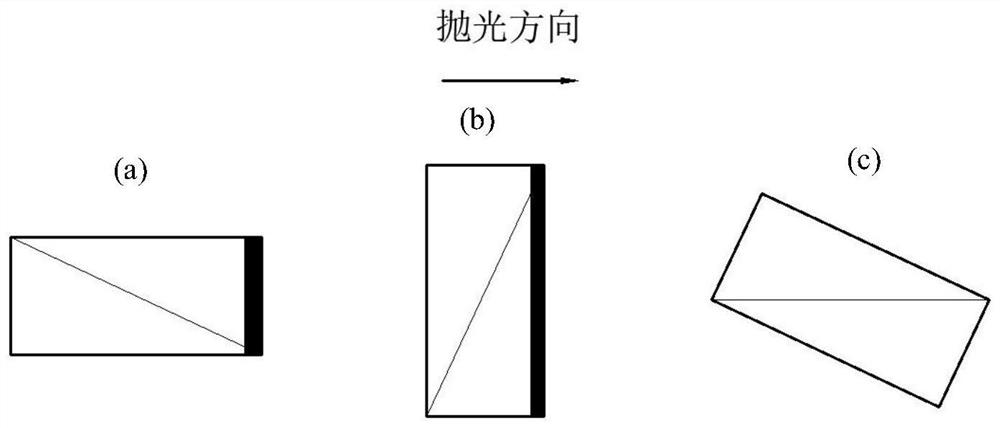

[0026] 4) Argon ion beam polishing: polishing the surface of the sample to be measured with a high-energy argon ion beam to obtain a sample for EBSD analysis.

[0027] In step 1) described in this example, the surface sample to be tested is processed into a sample of suitable size, especially the width of the surface area to be analyzed is controlled within 5 mm, which is convenient for sample preparation and ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com