Polyurethane material for curtain wall, building curtain wall profile and preparation method of building curtain wall profile

A polyurethane material and polyurethane technology, which is applied in buildings, building components, building structures, etc., can solve problems such as poor flame retardant performance, poor mechanical strength, and inability to meet, achieve excellent mechanical properties, improve aesthetics and applicability performance, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

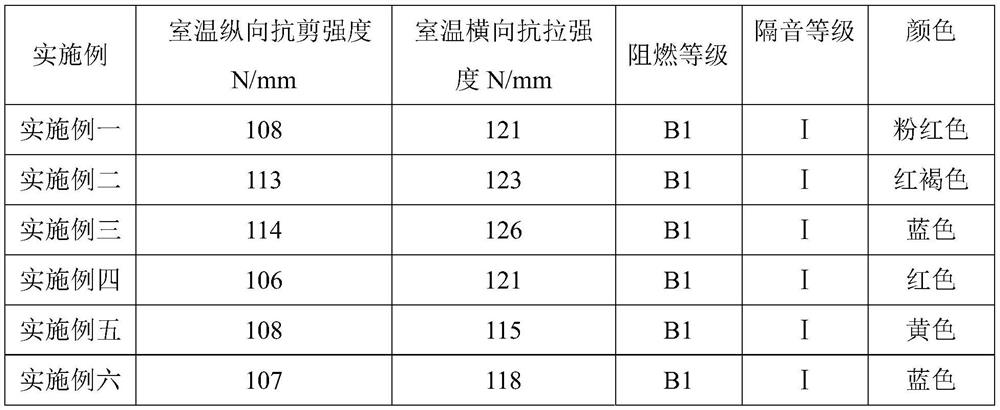

Examples

Embodiment 1

[0059] The polyurethane material for curtain wall described in this embodiment includes 50 parts of bicomponent fibers, 50 parts of polyol, 70 parts of polyisocyanate, 0.1 part of catalyst, 0.1 part of foaming agent, and 0.1 part of foam stabilizer in terms of mass fraction. parts, 5 parts of flame retardants, 15 parts of colorants, 10 parts of antistatic additives, 40 parts of sound-absorbing materials, 5 parts of preservatives, and 50 parts of water.

[0060] When the bicomponent fibers are side-by-side bicomponent fibers, the side-by-side bicomponent fibers are carbon fiber-polyurethane fibers;

[0061] The polyol is a polyether polyol; the catalyst is an amine catalyst; the foaming agent is monofluorodichloroethane; the foam stabilizer is a polyether modified organosilicon surfactant; the coloring The agent is manganese salt; the flame retardant is nitrogen-based flame retardant; the antistatic auxiliary agent is cetyltrimethylammonium chloride; the sound-absorbing materia...

Embodiment 2

[0072] The polyurethane material for curtain wall described in this embodiment includes 80 parts of fibers, 70 parts of polyols, 90 parts of polyisocyanates, 2.5 parts of catalysts, 2.5 parts of foaming agents, 2.5 parts of foam stabilizers, and 2.5 parts of foam stabilizers. 30 parts of burning agent, 50 parts of coloring agent, 30 parts of antistatic additives, 60 parts of sound-absorbing materials, 25 parts of preservatives, and 90 parts of water.

[0073] When the bicomponent fiber is a side-by-side bicomponent fiber, the bicomponent is glass fiber / polyurethane fiber.

[0074] The polyol is a polyester polyol; the catalyst includes an organic metal catalyst; the foaming agent is cyclopentane; the foam stabilizer is a polyether modified organosilicon surfactant; Valence iron salt; the flame retardant is phosphorus flame retardant; the antistatic auxiliary is octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate; the sound-absorbing material is foam metal; the preserva...

Embodiment 3

[0080] The polyurethane material for curtain wall described in this embodiment, in terms of mass fraction, includes 60 parts of bicomponent fibers, 60 parts of polyol, 90 parts of polyisocyanate, 2 parts of catalyst, 2 parts of foaming agent, and 2 parts of foam stabilizer. parts, 10 parts of flame retardants, 30 parts of colorants, 25 parts of antistatic additives, 50 parts of sound-absorbing materials, 10 parts of preservatives, and 80 parts of water. That is, when the flame retardant is 10 parts, the mass ratio of antistatic additives and preservatives is 5:2; when the added colorant is 30 parts, the mass ratio of bicomponent fiber: polyol: polyisocyanate: colorant is 1:1:1.5:0.5.

[0081] When the bicomponent fibers are sheath-core fibers, the sheath / core structure is polyurethane fibers / carbon fibers.

[0082] Polyol is polyether polyol; catalyst organometallic catalyst; foaming agent isopentane; foam stabilizer is polyether modified silicone surfactant; colorant is copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com