Organic-inorganic composite microsphere, battery diaphragm, preparation method of organic-inorganic composite microsphere, preparation method of battery diaphragm and battery

A technology of inorganic composite microspheres and battery separators, which is used in secondary batteries, battery pack parts, and secondary battery repair/maintenance, etc. Problems such as poor thickness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

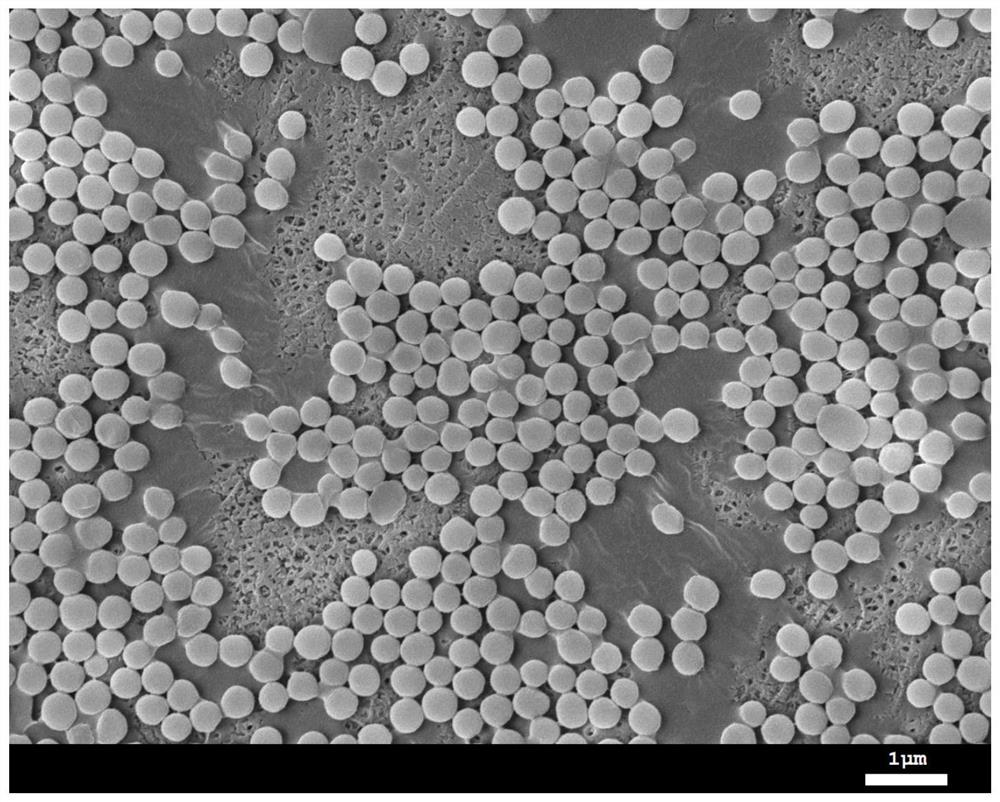

[0034] This embodiment prepares a kind of organic-inorganic composite microspheres, and its preparation method is as follows:

[0035] S1, adopt dianhydride monomer pyromellitic dianhydride and diamine monomer bis(4-aminophenyl) ether, and use aprotic polar N,N-dimethylformamide (DMF as solvent, according to single The mass ratio of the body and the solvent is 1:1, and it is placed in an ice-water bath to synthesize a polyamic acid (PAA) solution with a solid content of 12 wt% through a polymerization reaction, and then placed at a constant temperature of 50 °C for aging treatment to obtain molecular weight. Polyamic acid (PAA) solution with uniform distribution and intrinsic viscosity of 0.3dl / g;

[0036] S2, adding tetraethyl orthosilicate (TEOS) with a mass ratio of 10% to the polyamic acid (PAA) solution finally obtained in step S1, and sealing and stirring at room temperature for 6 hours to prepare a clear, transparent mixed uniform PAA / TEOS Mixed solution; then use PAA / ...

Embodiment 2

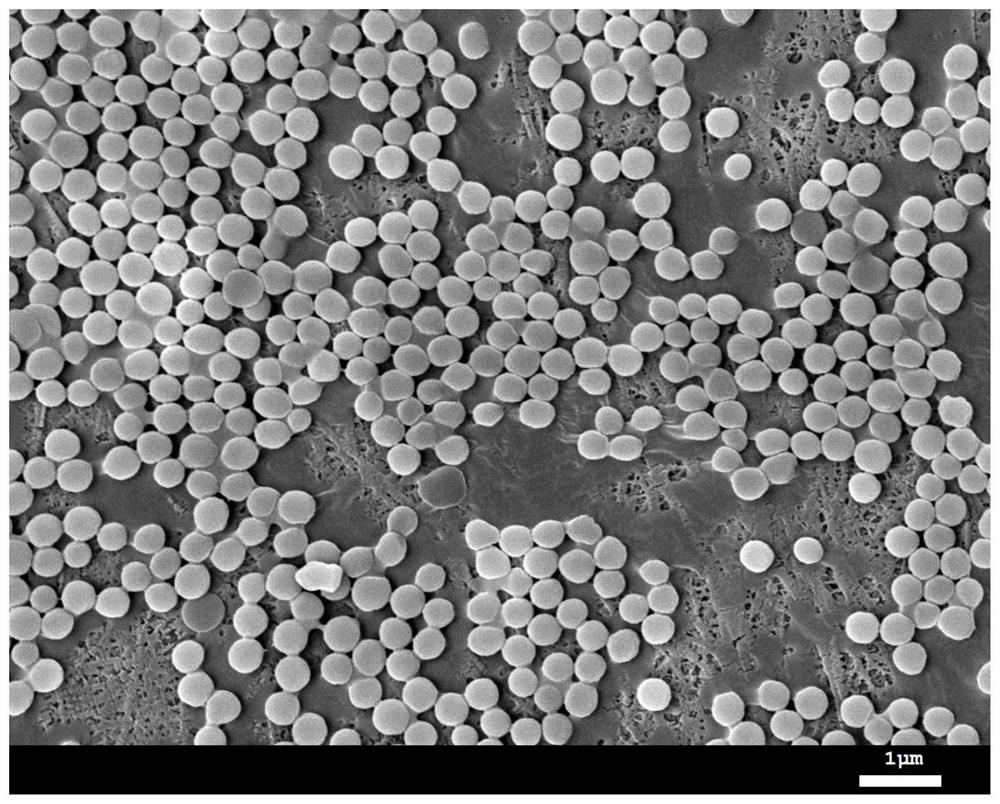

[0039] This embodiment prepares a kind of organic-inorganic composite microspheres, and its preparation method is as follows:

[0040] S1, according to the same operation as step S1 in Example 1, prepare a polyamic acid (PAA) solution;

[0041] S2, the polyamic acid (PAA) solution finally obtained in step S1 is used as spinning solution for electrospinning, and the spinning parameters are controlled to be positive pressure+50KV, negative pressure-10KV, spray distance 20cm, brushing speed 10cm / s, to prepare the second precursor microspheres;

[0042] S3. Place the second precursor microspheres prepared in step S2 in TiOSO with a concentration of 0.2 mol / L 4 In the solution, the complexation reaction is carried out at room temperature. Specifically, the -COOH on the surface of the second precursor microspheres will interact with TiO. 2+ Adsorption complexation reaction occurs; then it is placed in deionized water of the hydrolyzate, and the TiO 2+ Hydrolysis occurs to genera...

Embodiment 3

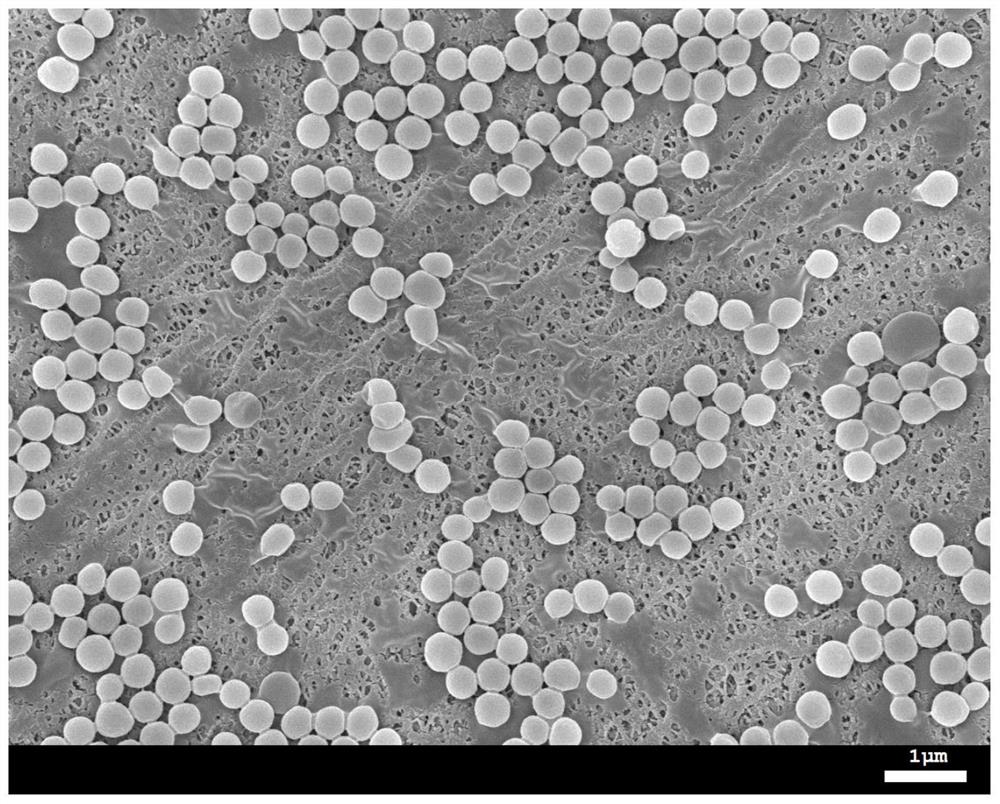

[0046] This embodiment prepares a battery separator, and the preparation method includes:

[0047] S1, take 9 parts of organic-inorganic composite microspheres prepared in Example 1, 1 part of sodium carboxymethyl cellulose (CMC), and 1 part of polyvinylpyrrolidone (PVP), and mix with water and ethanol in a volume ratio of 1:1 98 parts of the solvent were placed in a homogenizer and homogenized at a speed of 8000 rpm for 1 hour, and after mixing evenly, filtered through a 300-mesh screen to obtain a modified slurry;

[0048] S2. Using a flat blade coater, scrape the modified slurry prepared in step S1 on a polyethylene microporous base film with a coating gap of 100 μm. The polyethylene microporous base film is commercially available and has a thickness of 3 to 200 nm. , the porosity is 20%-80%, and the air permeability is 50-200s / 100cc; after the coating is completed, it is placed on an ultra-clean table to dry naturally, and then vacuum-dried at 60 °C for 12 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com