Prothioconazole and chlorothalonil compound water dispersible granule and preparation method thereof

A technology of prothioconazole and chlorothalonil, which is applied in the field of prothioconazole and chlorothalonil compounded water-dispersible granules and its preparation, can solve the problems of high decomposition rate of prothioconazole original drug, achieve good dispersion, The core-shell structure is uniform and the effect of avoiding decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

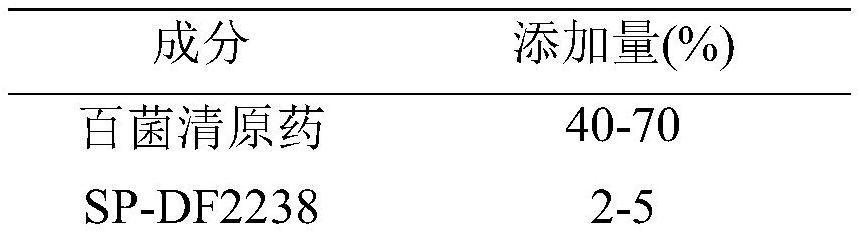

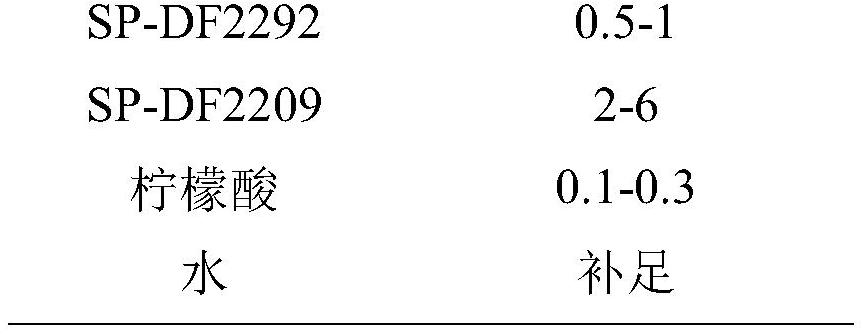

[0078] Step 1: 42.5% Bacillus clear suspension preparation

[0079]

[0080] The above components are put into the mixing kettle in turn, stirred evenly, through the sand mill wet sand grinding, sand grinding medium using 1.6-2.8 mm zirconia material, grinding temperature control below 50 °C, the material liquid grinding to 90% particle size (D90) less than 5 μm, to obtain a bacterium clear suspension B1.

[0081] Step 2: Prophiamazole suspension precursor preparation

[0082]

[0083] The above components are put into the mixing kettle in turn, stirred evenly, by the sand mill wet sand grinding, sand grinding medium using 1.6-2.8 mm zirconia material, grinding temperature control below 50 °C, the material liquid grinding to D90 (90% particle size) less than 5 μm, to obtain propylthiazole suspension precursor.

[0084] Step 3: Preparation of 21.25% nuclear-shell structure propioniazole suspension

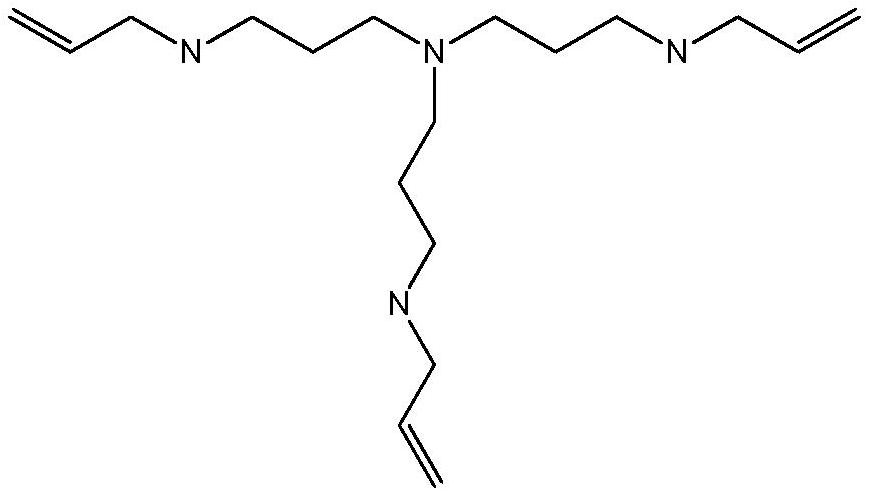

[0085]Step 3-1: Preparation of the core-shell structure prophiapazole: the acti...

Embodiment 2- Embodiment 7 and comparative example 2-7

[0096] Step 1: 42.5% Bacillus clear suspension preparation, with Example 1.

[0097] Step 2: Propethiazole suspension precursor preparation, basically the same as Example 1, the difference is that the amount of water added to ensure the core shell structure propylthiazole nuclear shell suspension total raw materials (including propionhiazole original drug, SP-DF2238, SP-DF2292, SP-DF2209, water, active chain transfer agent for the formation of the core shell structure of the large monomer, crosslinking agent, initiator and filler) added to the amount of 100 parts. Among them, the polyacrylic acid- polystyrene - RAFT reagent (PAA) used in a logarithmic ratio 27 -PSt 5 -RAFT), prepared by the preparation method in the master's thesis of Zhejiang University "Raft Emulsion Polymerization Mechanism and Preparation of Poly (Styrene-Butyl Acrylate-Styrene)".

[0098] Step 3: Preparation of 21.25% core-shell structure propioniziazole suspension:

[0099] Step 3-1: Step 1, with Example 1, ...

Embodiment 8

[0112] Preparation stability studies

[0113] The stability test of the preparation was carried out by liquid chromatography to detect the effective content of the original chinese medicine of the preparation, and the conditions for determination by high performance liquid chromatography were: mobile phase: acetonitrile: aqueous solution of ammonium carbonate (0.01mol / L) = 45:55; wavelength: 220 nm; Flow rate: 1.0ml / min.

[0114] Prophiamazole (non-core shell structure) prepared in proportion 1 + bacterium clear water dispersible granules and Example 1-7 and prophimethiazole (nuclear shell structure) prepared in proportion 2-7 + bacterium clear water dispersible granules under the above conditions the decomposition rate is shown in Table 5.

[0115] Table 5 contrasts the proportion of 1-7 and Example 1-7 water dispersible granules in prophiazole active content decomposition rate

[0116] sample Decomposition rate Contrast ratio 1 (non-core shell structure) 65% E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com