Zinc-containing Anderson type heteropolyacid flame-retardant smoke suppressant and preparation method thereof

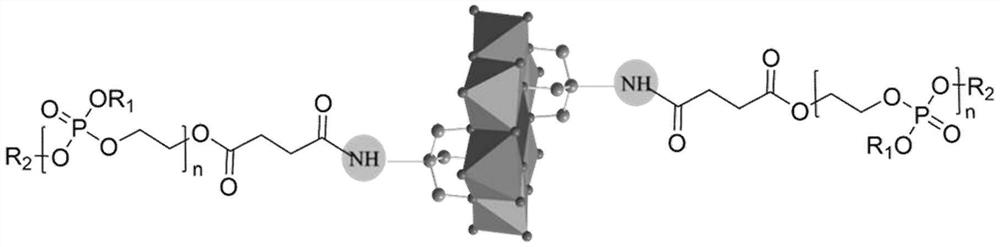

The technology of a heteropoly acid and a smoke suppressant is applied in the field of zinc-containing Anderson type heteropoly acid flame retardant and smoke suppressant and its preparation, which can solve the problem that the polyoxometalate has poor compatibility with a substrate and a single organic modification method. , low flame retardant efficiency and other problems, to achieve the effect of comprehensive performance improvement, high catalytic activity, high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

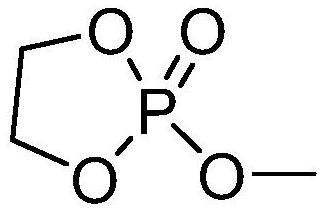

[0028] (1) Preparation of 2-methoxy-1,3,2λ5-dioxaphosphalane 2-oxide polymerized monomer: under a nitrogen atmosphere, add a 1000 mL condensing reflux tube and a magnetic stirring bar to a In the three-necked flask, add reactants methanol (0.302mol), triethylamine (0.302mol) and 600mL tetrahydrofuran solution, 2-chloro-2-oxygen-1,2,3-dioxaphosphalane (0.302mol) It was diluted with 85 mL of tetrahydrofuran solution and added dropwise to the mixed solution at 0°C. The reaction mixture was stored at -20°C without stirring for 6h. After the reaction was completed, the reaction mixture was filtered with tetrahydrofuran and triethylamine to remove salts. The yellow solution obtained by filtration was subjected to rotary evaporation to form a concentrated solution, which was then washed with CaH 2 The extraction solution is subjected to vacuum distillation to finally form 2-methoxy-1,3,2λ5-dioxaphosphalane 2-oxide, and the specific structural formula is:

[0029]

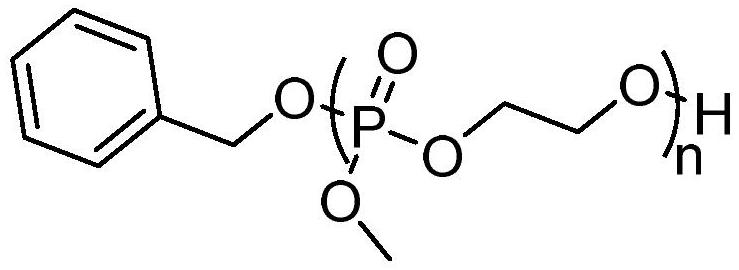

[0030](2) Pr...

Embodiment 2

[0036] (1) Preparation of 2-isopropoxy-2-oxo-1,3,2-dioxaphosphalane 2-oxide polymerized monomer: under nitrogen atmosphere, to a room equipped with a condenser reflux tube and Add reactant triethylamine (71.9mmol), isopropanol (131mmol) and 100mL of tetrahydrofuran solution, 2-chloro-2-oxygen-1,2,3-dioxaphos-pentane to the three-necked flask of magnetic stirring bar (66.8 mmol) was diluted with 40 mL of tetrahydrofuran, and slowly added dropwise to the mixed solution at -78°C for 1 h. The reaction mixture was stirred at -78°C for 11 h and at 25°C for 9 h. After the reaction was completed, the reaction mixture was filtered with tetrahydrofuran and triethylamine to remove salts. After the yellow solution obtained by filtration was turned into a concentrated solution by rotary evaporation, it was washed with CaH 2 The extraction solution is subjected to vacuum distillation to finally form a colorless oily product 2-isopropoxy-2-oxo-1,3,2-dioxaphosphalane 2-oxide, the specific s...

Embodiment 3

[0044] (1) Preparation of 2-ethoxy-2-oxo-1,3,2-dioxaphosphalane 2-oxide polymerized monomer: under a nitrogen atmosphere, a condensing reflux tube and a magnetic In the 500mL three-necked flask of the stirring bar, the reactants triethylamine (52.4mmol), ethanol (65.2mmol) and 200mL of tetrahydrofuran solution, 2-chloro-2-oxygen-1,2,3-dioxaphosphalane ( 43.5 mmol) was diluted with 70 mL of tetrahydrofuran, and slowly added dropwise to the mixed solution at -78 °C for 5 h. The reaction mixture was stirred at -68°C for 2h and at 25°C for 13h. After the reaction was completed, the reaction mixture was filtered with tetrahydrofuran to remove salts. After the yellow solution obtained by filtration is rotated to form a concentrated solution, the solution is extracted with CaH2 and subjected to vacuum distillation to finally form a colorless oily product 2-ethoxy-2-oxo-1,3,2-dioxo Phosphalane 2-oxide, the specific structural formula is:

[0045]

[0046] (2) Preparation of PPEs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com