Method, device, medium and equipment for improving trimming quality of high-strength steel

A high-strength steel and trimming technology, which is applied in the field of steel rolling, can solve the problems of inability to ensure the trimming quality of high-strength series continuous annealing products and galvanized products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to better understand the above technical solutions, the technical solutions of the embodiments of the present specification will be described in detail below through the accompanying drawings and specific embodiments. The detailed description is not intended to limit the technical solutions of the present specification, and the embodiments of the present specification and the technical features in the embodiments may be combined with each other under the condition of no conflict.

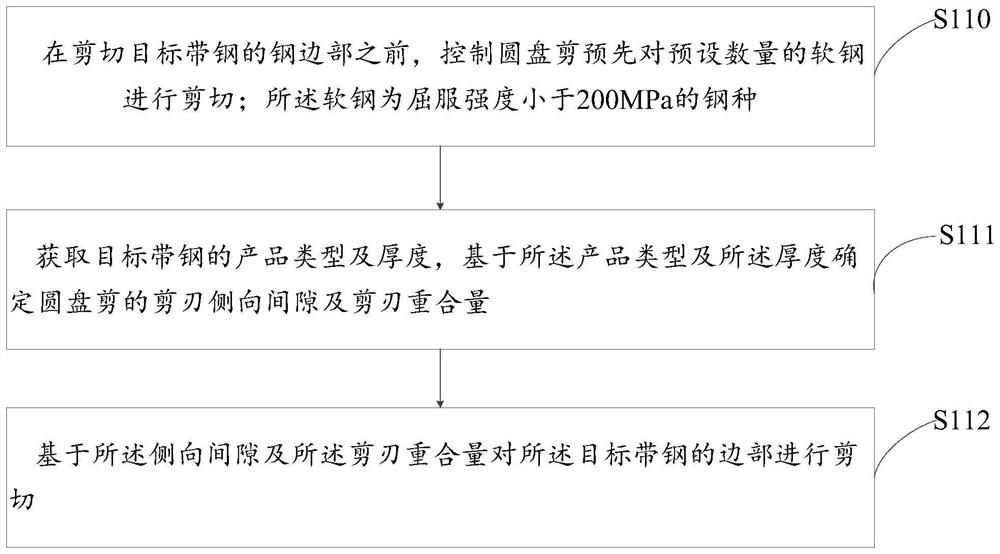

[0054] This embodiment provides a method for improving the quality of high-strength steel trimming, such as figure 1 As shown, the method mainly includes the following steps:

[0055] S110, before cutting the steel edge of the target strip, control the disc shear to cut a preset amount of mild steel in advance; the mild steel is a steel with a yield strength less than 200 MPa;

[0056] Because the target strip steel is high-strength steel, the high-strength steel itself has high str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com