Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of small grain size, hindering the photoelectric conversion rate of cells, and interface defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

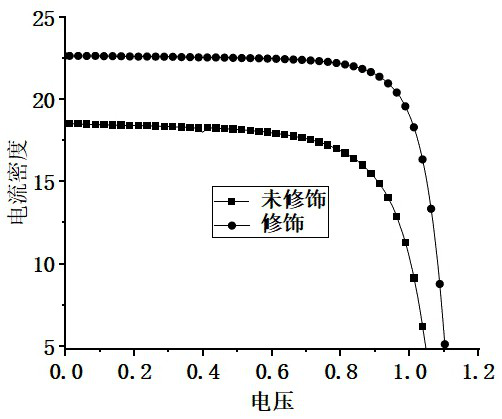

Embodiment 1

[0054] This embodiment provides a preparation method of a perovskite solar cell, comprising the following steps:

[0055] 1) The FTO conductive glass was ultrasonically cleaned with soapy water, deionized water, absolute ethanol, and acetone, and then cleaned with ultraviolet ozone.

[0056] 2) The 15 wt% SnO 2 The colloidal solution was diluted with deionized water to obtain 3.75 wt% SnO 2 colloidal solution. The prepared 3.75 wt% tin oxide colloidal solution was sucked up with a plastic tip dropper, covered with FTO conductive glass, spin-coated at 4000 rpm for 35 s, and then annealed at 140 °C for 35 min to obtain an electron transport layer. Dissolve 0.5 mg of the metal chelating color developer amino black 10B in 1 ml of absolute ethanol, use a glue tip dropper to draw the solution and cover it with the FTO conductive glass coated with the electron transport layer, spin at 3000 rpm for 30 s, Annealed at 100 °C for 10 min.

[0057] 3) The PbI 2 (7.50 g) and CsI (0.30 ...

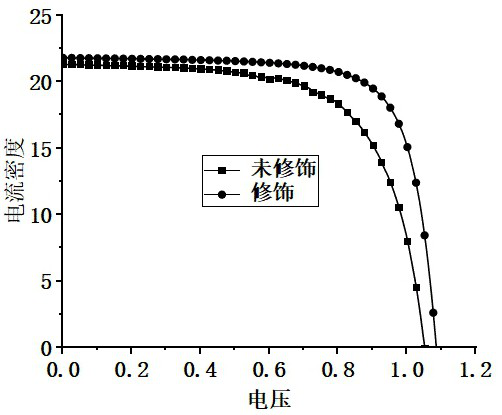

Embodiment 2

[0062] This embodiment provides a preparation method of a perovskite solar cell, comprising the following steps:

[0063] 1) The FTO conductive glass was ultrasonically cleaned with soapy water, deionized water, absolute ethanol, and acetone, and then cleaned with ultraviolet ozone.

[0064] 2) The 15 wt% SnO 2 The colloidal solution was diluted with deionized water to obtain 3.75 wt% SnO 2 colloidal solution. The prepared 3.75 wt% tin oxide colloidal solution was sucked with a plastic tip dropper, covered with FTO conductive glass, spin-coated at 4000 rpm for 35 s, and then annealed at 150 °C for 30 min to obtain an electron transport layer. Dissolve 0.5 mg of the metal chelating color developer red phenanthroline disulfonate in 1 ml of anhydrous ethanol, draw the solution with a plastic tip dropper and cover it with the FTO conductive glass coated with the electron transport layer, spin at 3000 rpm. After coating for 30 s, it was annealed at 100 °C for 10 min.

[0065] 3...

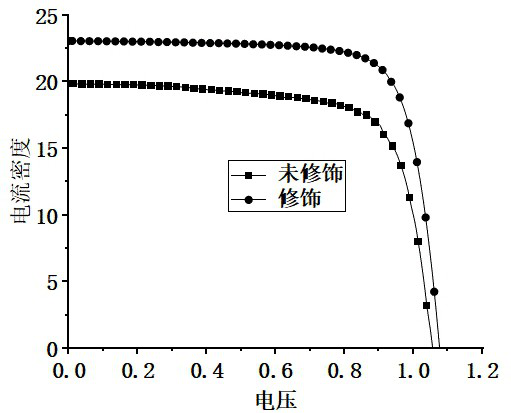

Embodiment 3

[0070] This embodiment provides a preparation method of a perovskite solar cell, comprising the following steps:

[0071] 1) The FTO conductive glass was ultrasonically cleaned with soapy water, deionized water, absolute ethanol, and acetone, and then cleaned with ultraviolet ozone.

[0072] 2) The 15 wt% SnO 2 The colloidal solution was diluted with deionized water to obtain 3.75 wt% SnO 2 colloidal solution. The prepared 3.75 wt% tin oxide colloidal solution was sucked with a plastic tip dropper, covered with FTO conductive glass, spin-coated at 4000 rpm for 35 s, and then annealed at 160 °C for 35 min to obtain an electron transport layer. Dissolve 0.5 mg of the metal chelating color developer amino black 10B in 1 ml of absolute ethanol, use a glue tip dropper to draw the solution and cover it with the FTO conductive glass coated with the electron transport layer, spin at 3000 rpm for 30 s, Annealed at 100 °C for 10 min.

[0073] 3) The PbI 2 (7.20 g), CsI (0.40 g) wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com