Active control vibration reduction system and method based on electro-hydraulic composite cylinder

An electro-hydraulic composite, active control technology, applied in vibration suppression adjustment, spring/shock absorber, fluid pressure actuating device, etc., can solve problems such as limiting the application of electro-hydraulic cylinders, poor ability to carry shocks, etc., to improve reliability. durability and service life, the effect of mitigating shock loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

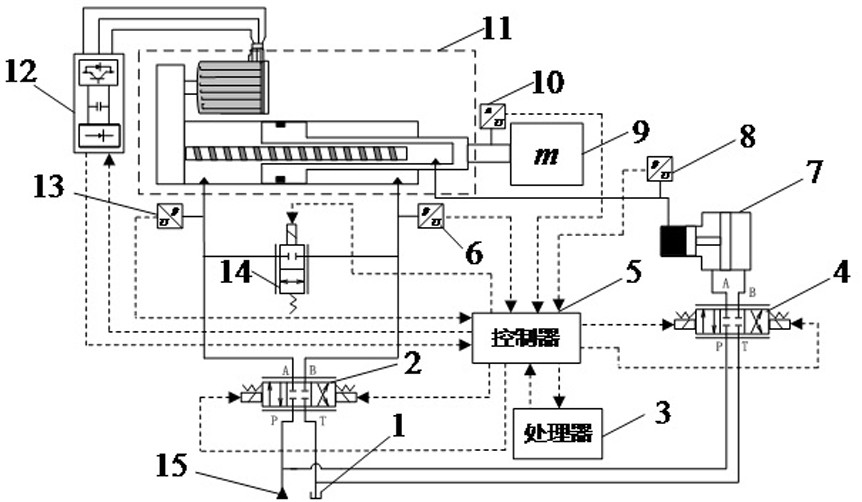

[0038] as attached figure 1 As shown, an active control vibration reduction system based on an electro-hydraulic compound cylinder includes a fuel tank 1, a first electromagnetic reversing valve 2, a processor 3, a second electromagnetic reversing valve 4, a controller 5, and a first pressure sensor 6 , booster cylinder 7 , second pressure sensor 8 , mass 9 , acceleration sensor 10 , electro-hydraulic compound cylinder 11 , driver 12 , third pressure sensor 13 , electromagnetic proportional switch valve 14 , power source 15 .

[0039] The power source 15 is communicated with the oil inlet of the first electromagnetic reversing valve 2 and the oil inlet of the second electromagnetic reversing valve 4, and the oil tank 1 is connected with the oil return port of the first electromagnetic reversing valve 2 and the second electromagnetic reversing valve. The oil return port of 4 is connected.

[0040] The electro-hydraulic compound cylinder 11 includes a rodless cavity, a rod cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com