Stationary constant-velocity universal joint

A constant velocity universal joint, fixed technology, used in elastic couplings, mechanical equipment, couplings, etc., can solve the problem of high impact force, achieve durability, suppress heat, and increase load capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below, based on Figure 1 to Figure 22 , to describe the embodiment of the present invention.

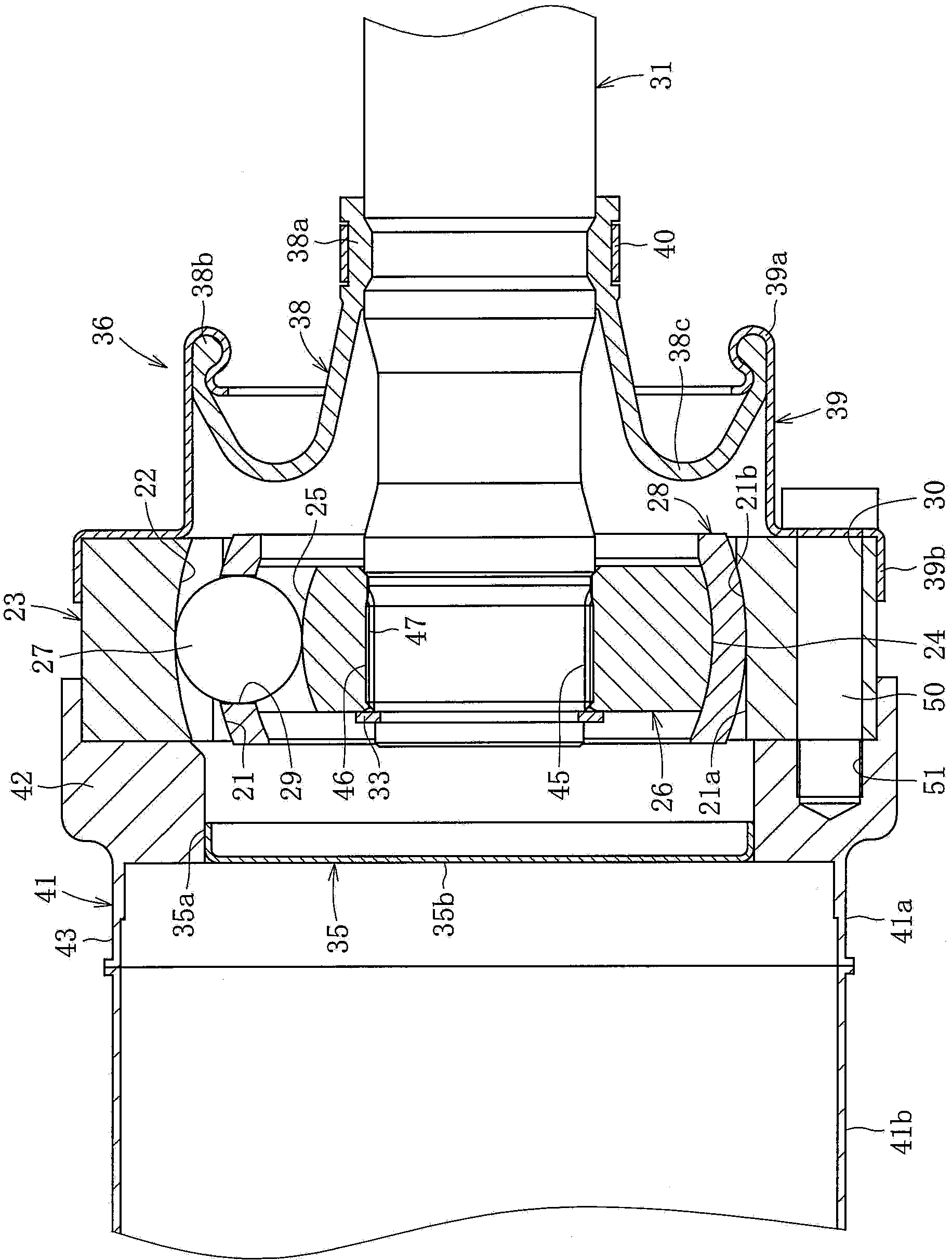

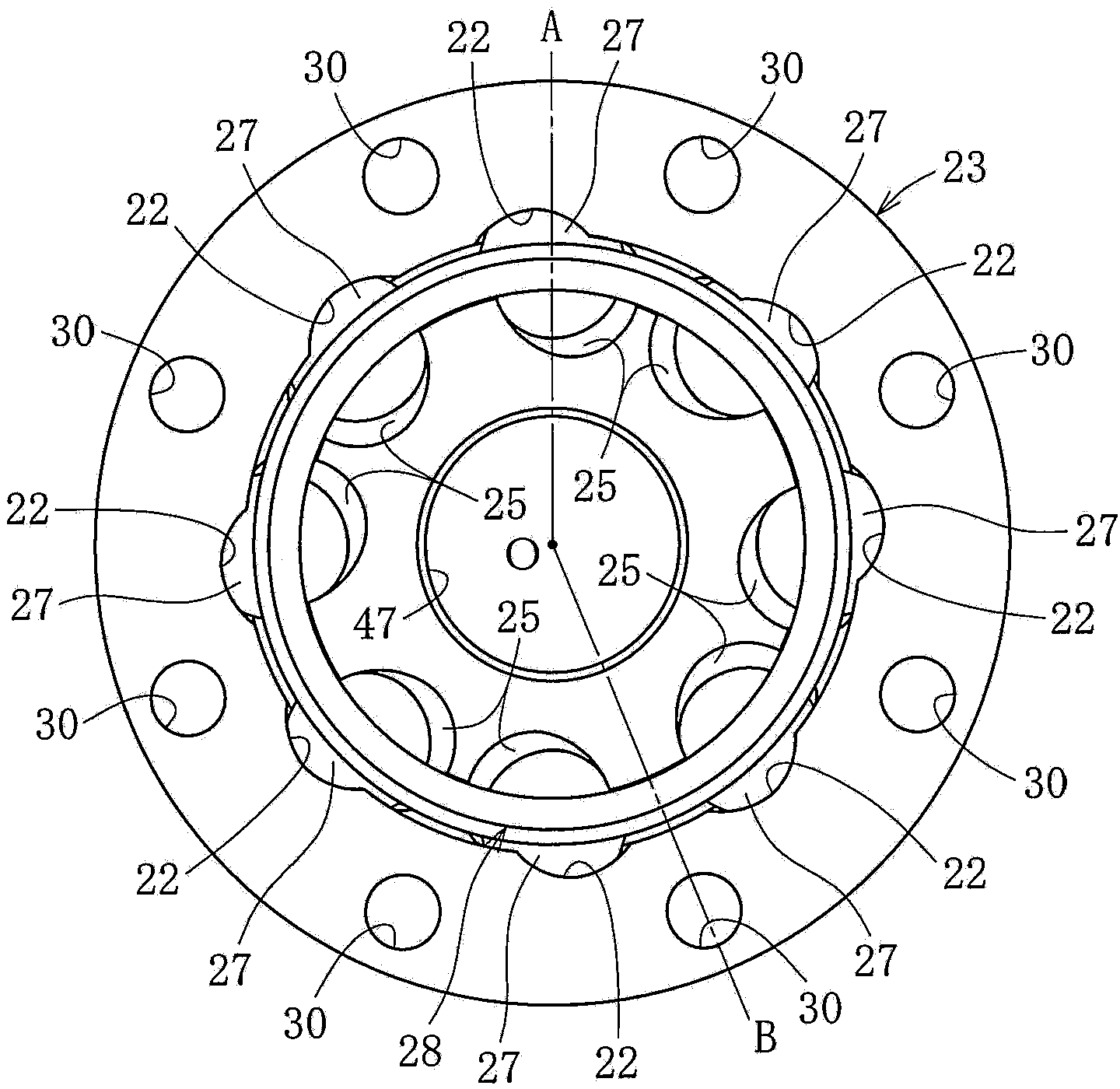

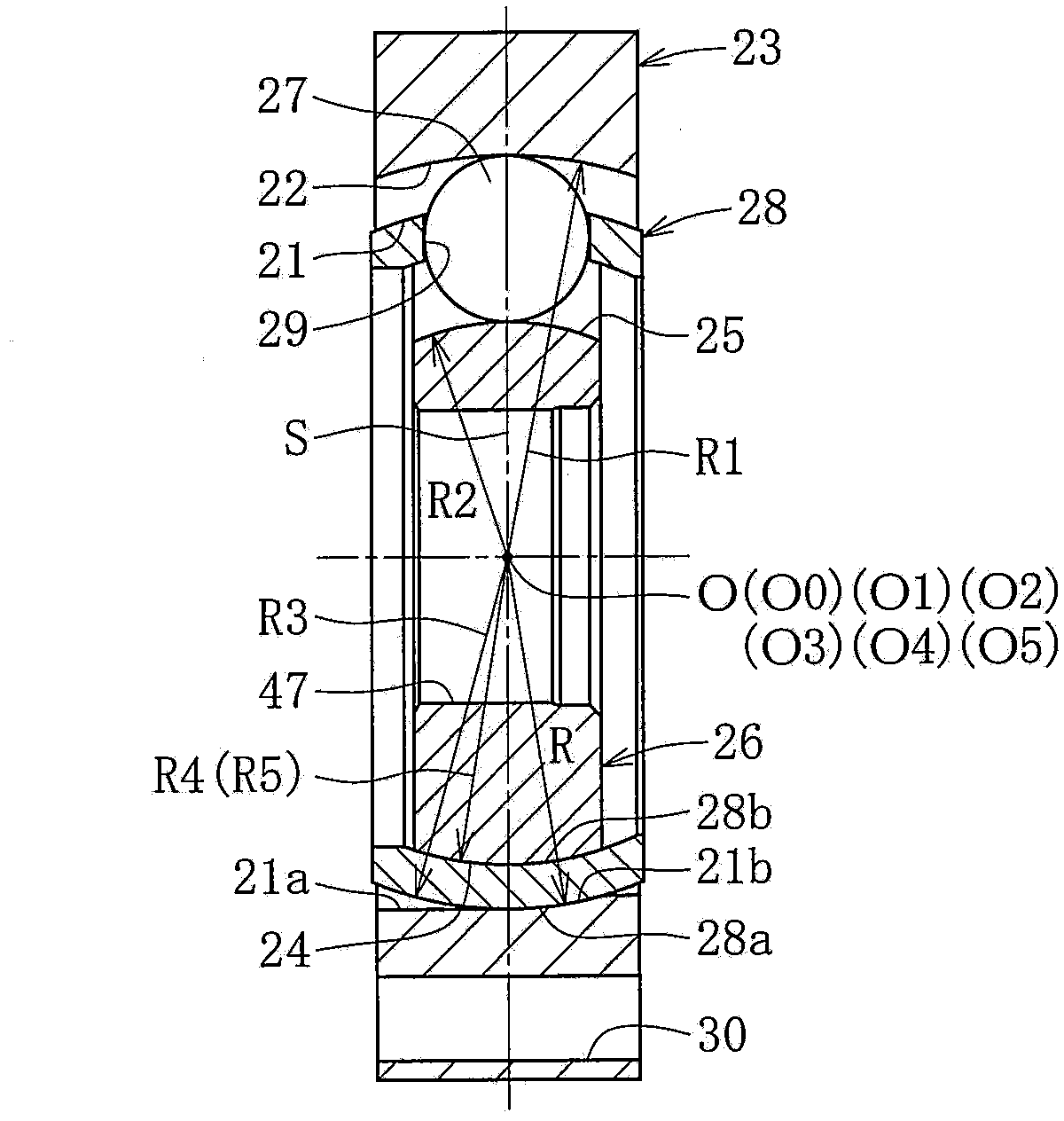

[0059] Such as Figure 1 ~ Figure 3 As shown, the fixed constant velocity universal joint according to the first embodiment of the present invention includes: an outer joint member 23 having a plurality (eight) of raceway grooves 22 axially formed on an inner diameter surface 21; The inner joint member 26 with a plurality of (eight) raceway grooves 25 formed in the axial direction; A plurality (eight) of torque transmission balls 27 on the track; and a cage 28 that holds the torque transmission balls 27 and is interposed between the inner diameter surface 21 of the outer joint member 23 and the outer diameter surface 24 of the inner joint member 26 .

[0060] A female spline 45 is formed on the inner diameter surface of the hole 47 of the inner joint member 26, and a male spline 46 of the shaft 31 is fitted into the hole 47 of the inner joint member 26. The female spline 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com