A structure of a load-carrying vehicle

The technology of a loading vehicle and frame, applied in the field of loading vehicle structure, can solve the problems of low delivery efficiency of express packages, inability to ensure delivery of express packages on time, and high labor intensity, so as to ensure delivery quality, simple structure, and reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

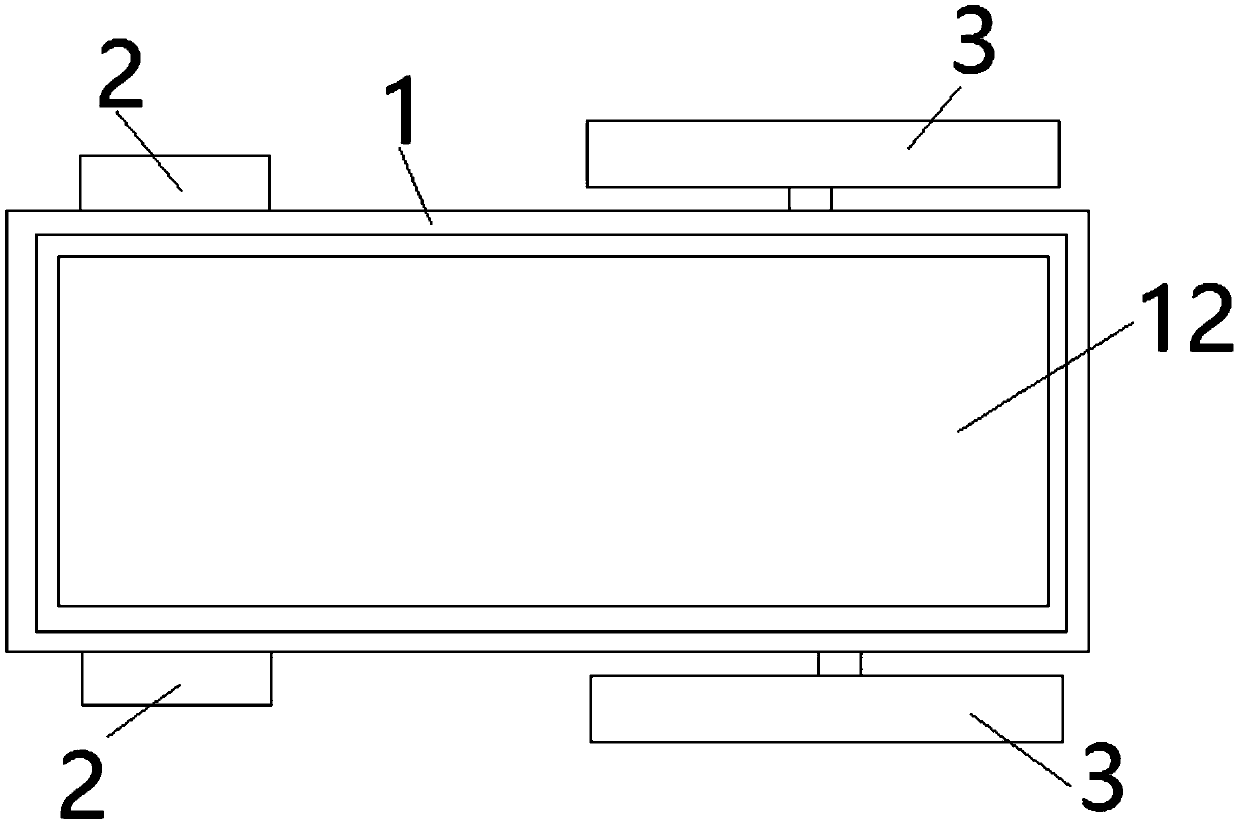

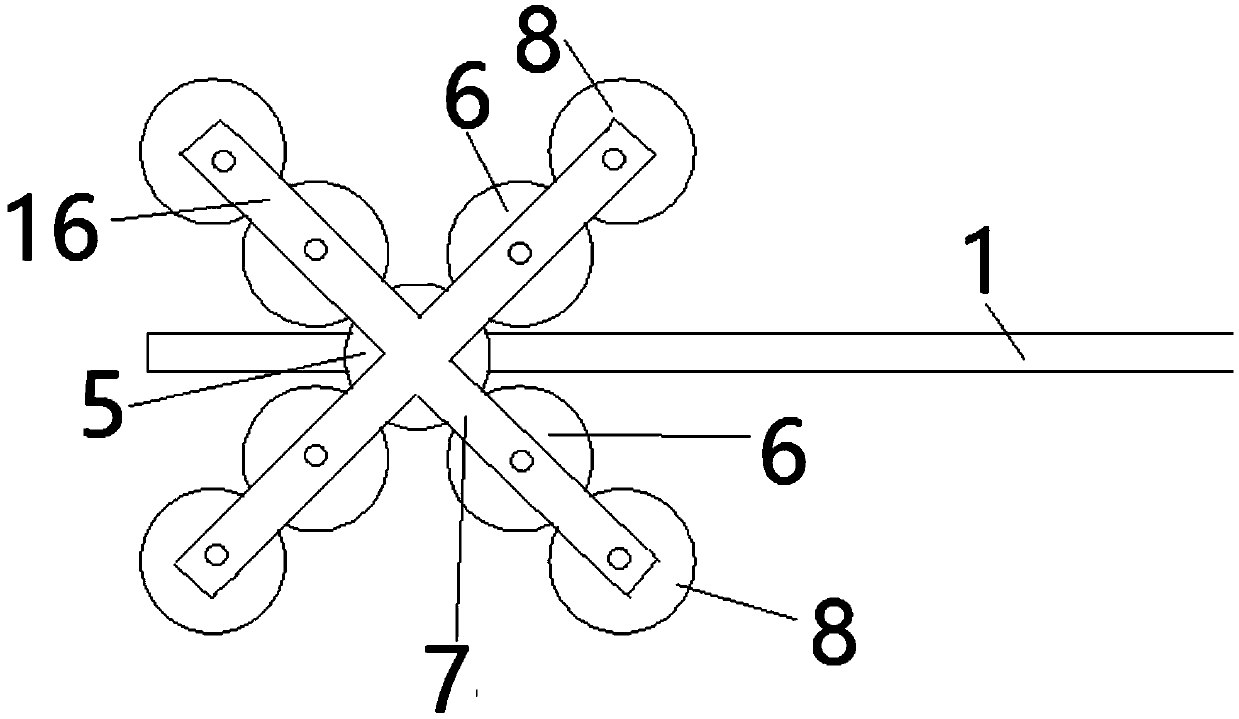

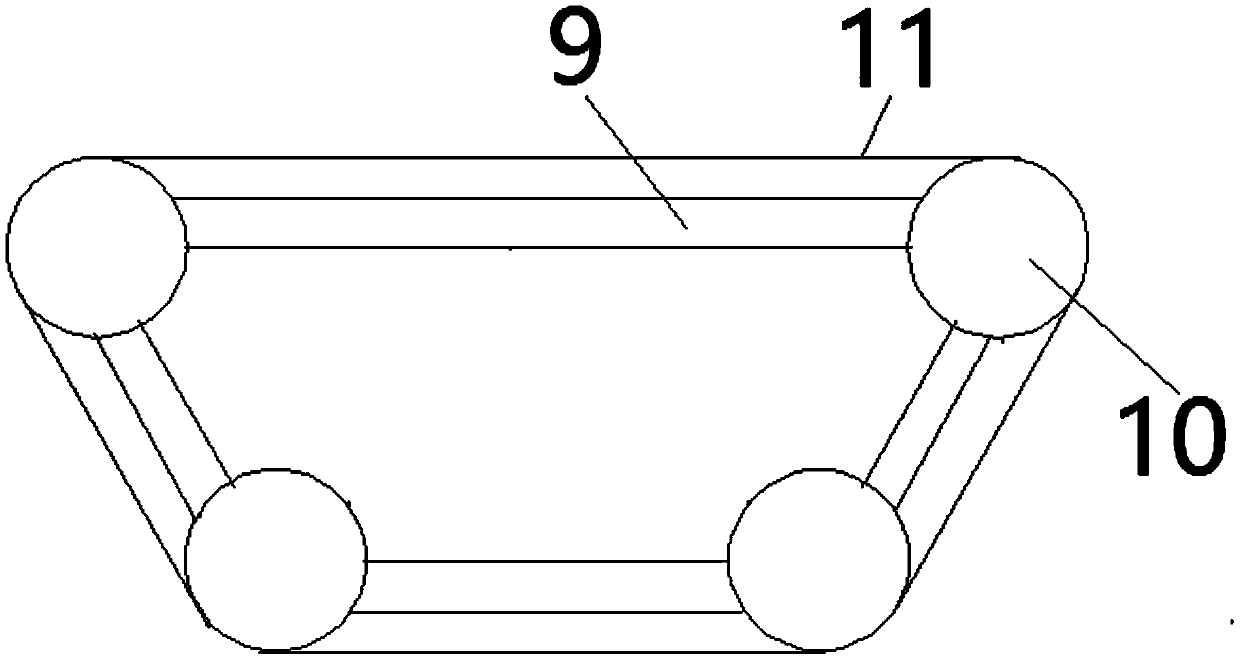

[0019] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed description: as attached figure 1 - attached image 3 As shown, the present invention is a kind of loading vehicle structure, and described loading vehicle structure comprises vehicle frame 1, and two front wheels 2 and two rear wheels 3 are installed on vehicle frame 1, and motor 4 is installed on vehicle frame 1, The motor 4 is connected with a front wheel 2 through a drive shaft, the motor 4 is connected with another front wheel 2 through another drive shaft, and the motor is connected with the control part 15 capable of controlling the start and stop of the motor. The front wheel 2 is a planetary gear train, and the front wheel T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com