Transfer, stacking and lifting device of sheet materials and using method

A transfer device and stacking technology, applied in the stacking, transportation and packaging of objects, conveyors, etc., can solve problems such as increased production costs, hidden safety hazards, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

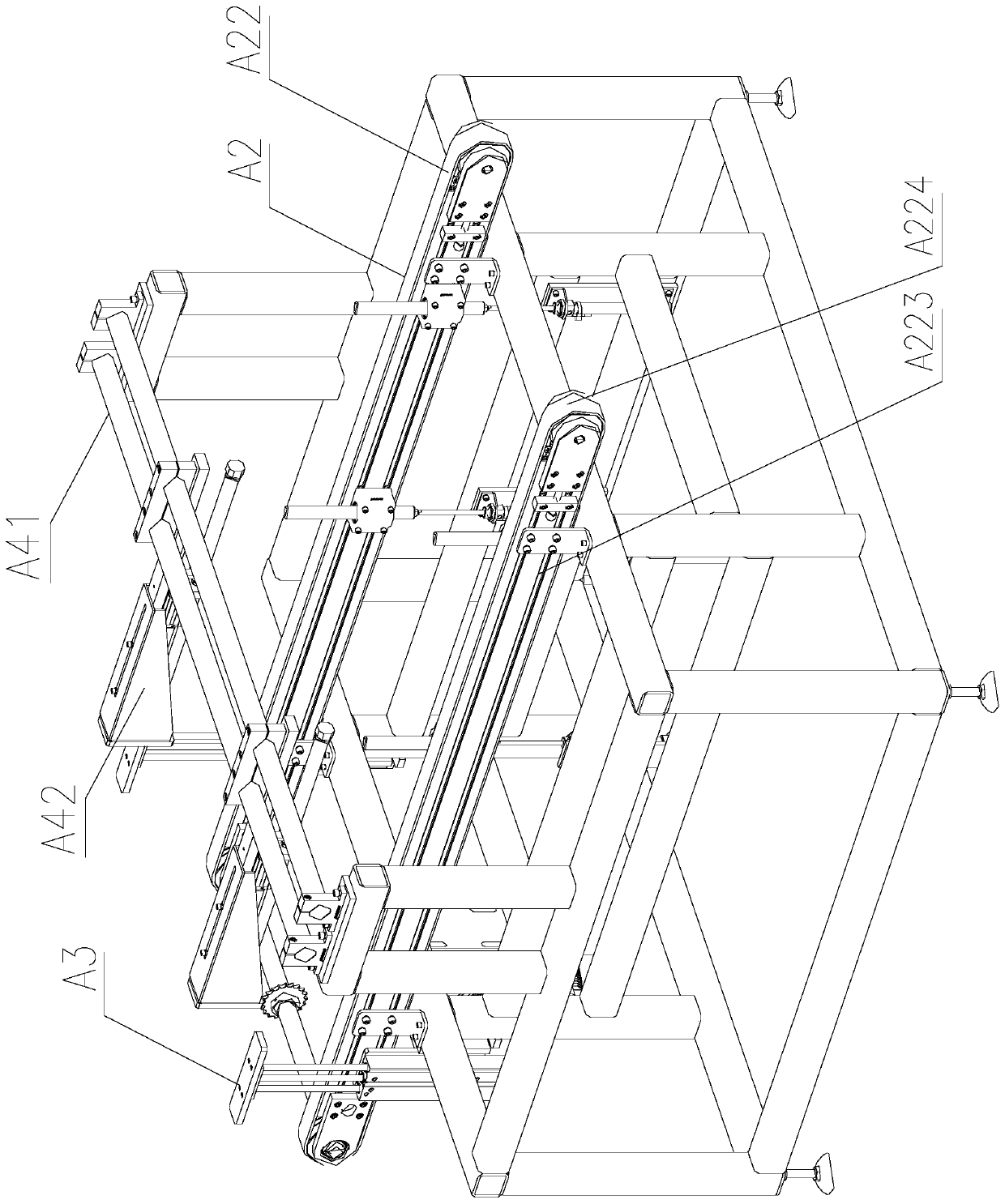

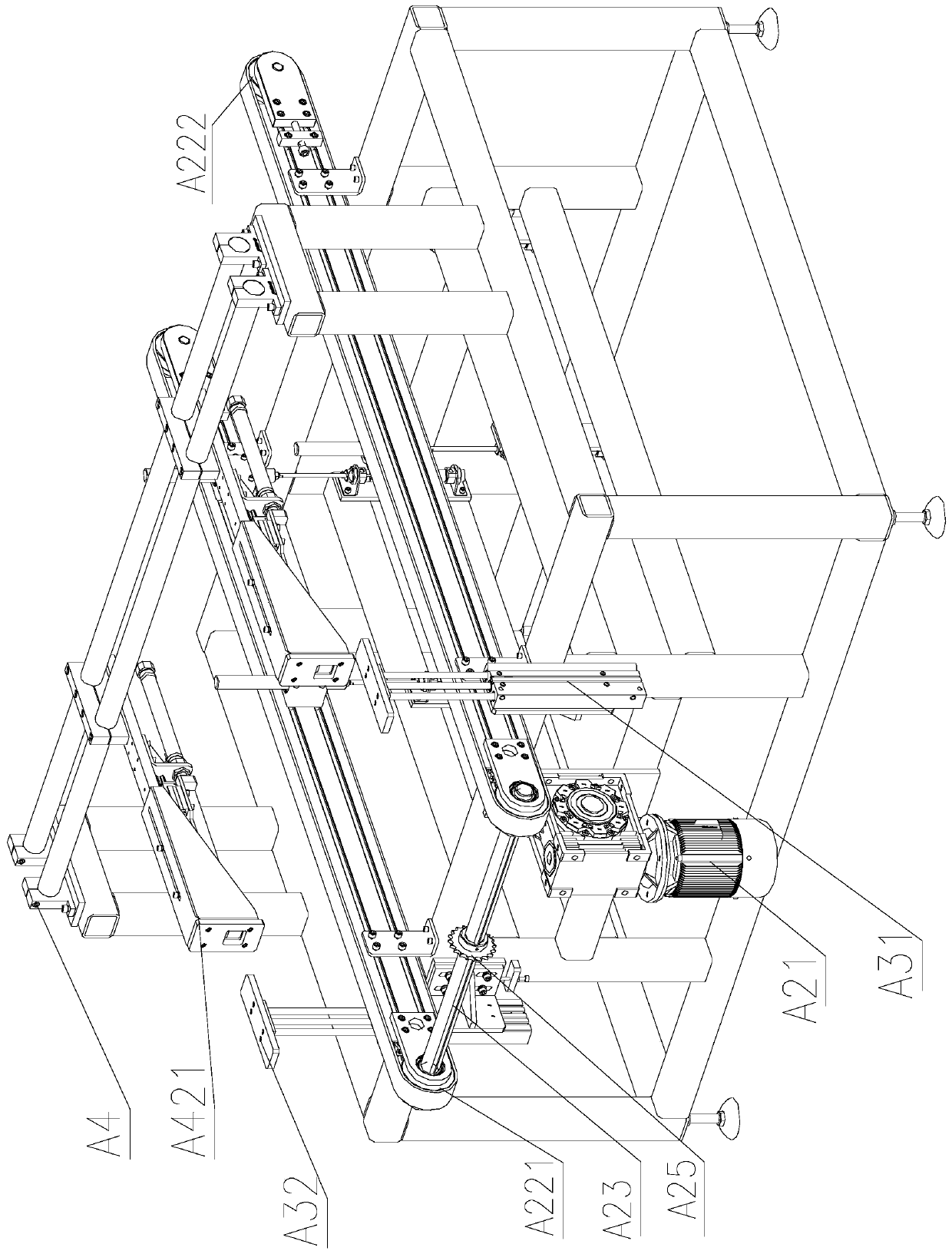

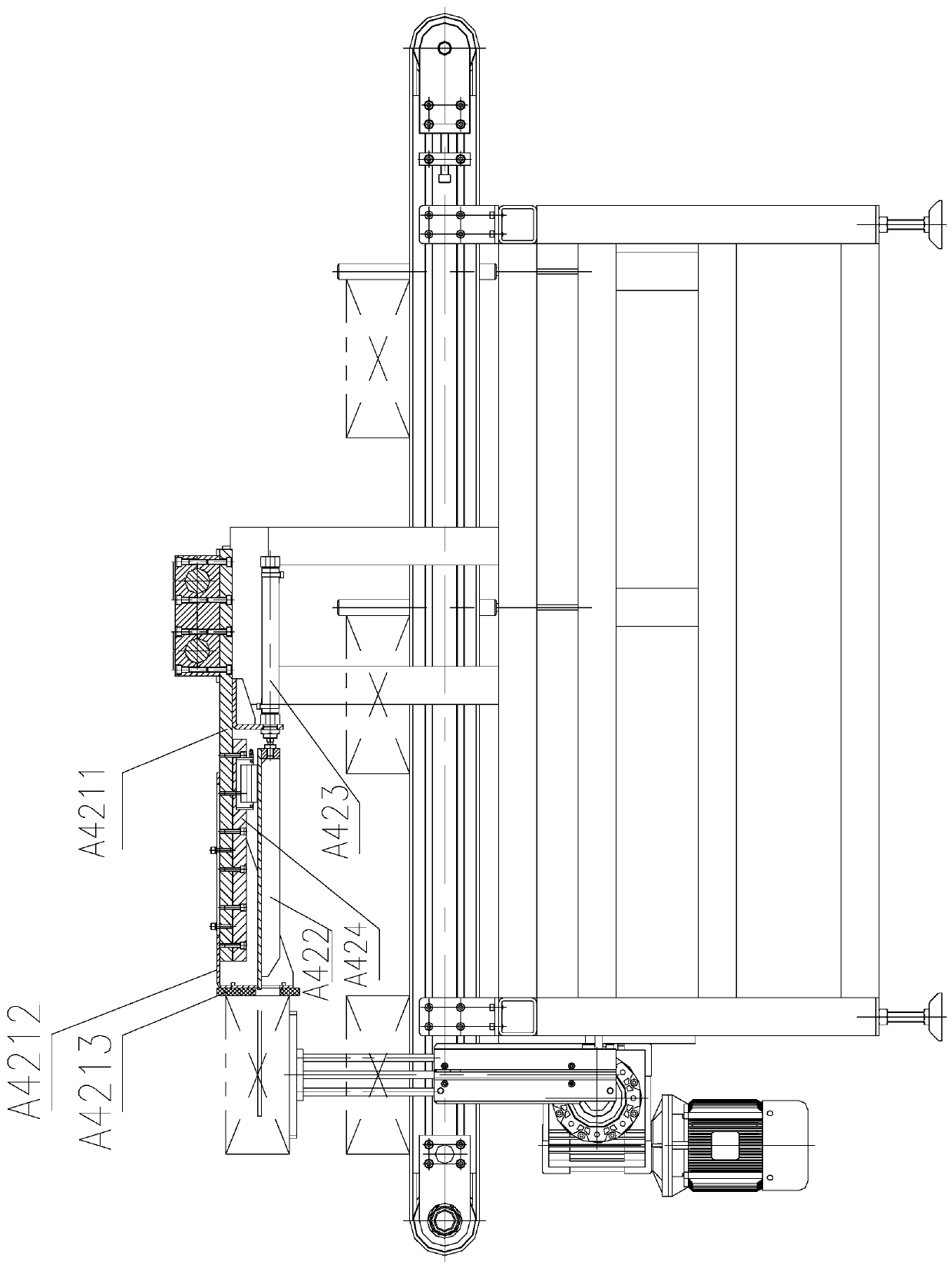

[0080] The present invention as Figure 1-5 As shown, including sequentially connected transfer device and stacking lifting device;

[0081] The transfer device includes a transfer frame A1, a conveying assembly A2 and a pair of docking assemblies A3;

[0082] The conveying assembly A2 includes a motor A21 fixedly arranged on the transfer frame A1 and a pair of belt transmission mechanisms A22 symmetrically arranged on the top of the transfer frame A1;

[0083] A synchronous rotating shaft A23 is arranged between the pair of belt transmission mechanisms A22;

[0084] The rotating shaft of the motor A21 is provided with a driving gear A24, and the synchronous rotating shaft A23 is provided with a driven gear A25 fixedly connected with the driving gear A24; the driving gear A24 is connected to the driving gear A24 through a chain Driven gear A25 transmission connection;

[0085] The motor A21 drives the driving gear A24 to rotate, and the driving gear A24 drives the driven ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com