Flame-retardant antistatic polyester wall cloth and preparation process thereof

A flame retardant, antistatic, preparation technology, applied in dyeing, passive house, fiber treatment, etc., can solve the problems of long time consumption, rough and thick fabric, easy dripping and volatilization, etc., to reduce the risk factor and enhance hydrophilicity The effect of hygroscopicity and simple overall process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

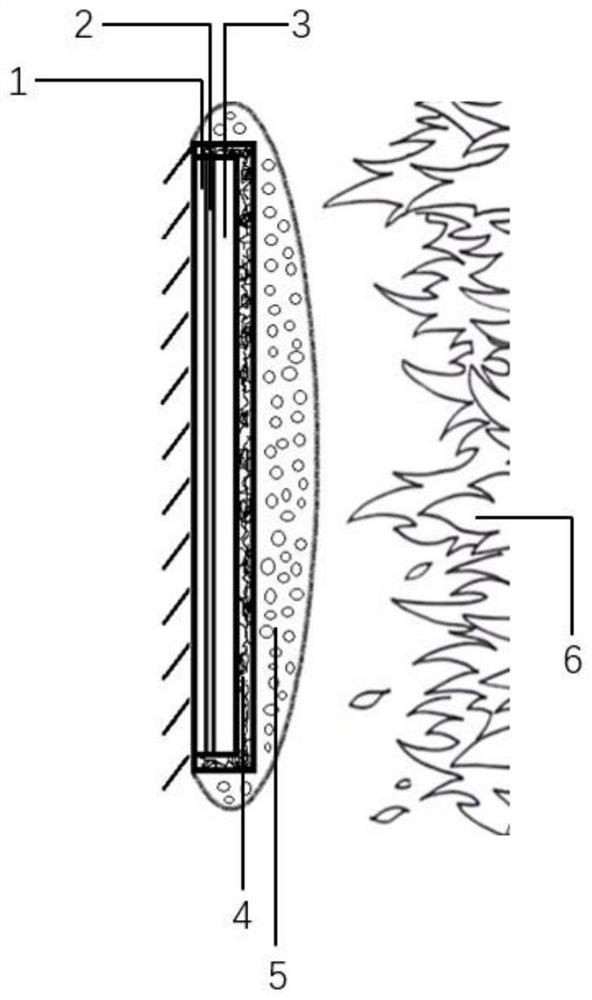

[0034] Example 1. A flame retardant and antistatic polyester wall covering and a preparation process thereof, comprising the following steps: figure 1 As shown, it includes a base fabric layer 1 and a surface fabric layer 3 , a hot melt adhesive layer 2 is arranged between the base fabric layer 1 and the surface fabric layer 3 , and a flame retardant and heat insulation layer 4 is arranged on the surface of the surface fabric layer 3 .

[0035] The flame-retardant and heat-insulating layer 4 is a CS / MMT (chitosan / sodium-modified montmorillonite) flame-retardant and heat-insulating layer.

[0036] The base fabric layer 1 is a pure cotton woven fabric, and the surface fabric layer 3 is a polyester fabric.

[0037] A preparation process of flame retardant and antistatic polyester wall covering,

[0038] Step A, the polyester fabric grey fabric is subjected to dipping alkali reduction process treatment to obtain A product;

[0039] In step B, product A is dyed to obtain product B...

Embodiment 2

[0053] Example 2. A flame retardant and antistatic polyester wall covering and a preparation process thereof, comprising the following steps: figure 1 As shown, the structure is firstly that the base fabric layer 1 and the surface fabric layer 3 are bonded and combined by the hot melt adhesive layer 2, and the base fabric layer 1 is a pure cotton woven fabric, which is pasted through the glutinous rice glue after brushing the acrylic emulsion base film. On the wall, the surface cloth layer 3 is a polyester fabric, and its surface is covered with a CS / MMT flame-retardant and heat-insulating layer 4.

[0054] The CS is chitosan, and the MMT is sodium-modified montmorillonite.

[0055] The thickness of the pure cotton woven fabric of the base fabric layer 1 is 0.3 mm, and the thickness of the polyester fabric of the surface fabric layer 3 is 0.5 mm.

[0056] The preparation process of the flame retardant and antistatic polyester wall covering is as follows:

[0057] Pre-treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com