Two-for-one twister for processing artificial environment-friendly fiber yarn

A two-for-one twisting machine and fiber yarn technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of fluff and dust, reduce displacement and shaking, improve fixing effect, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

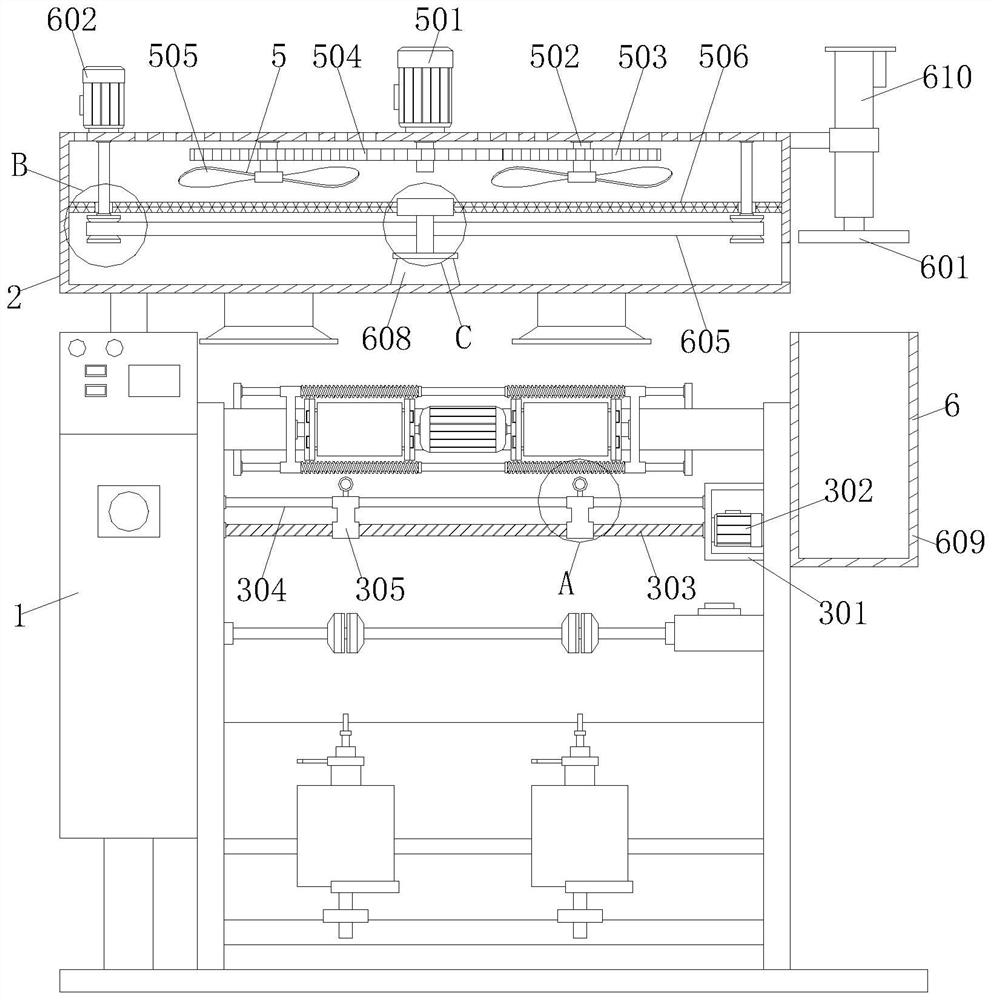

Embodiment 1

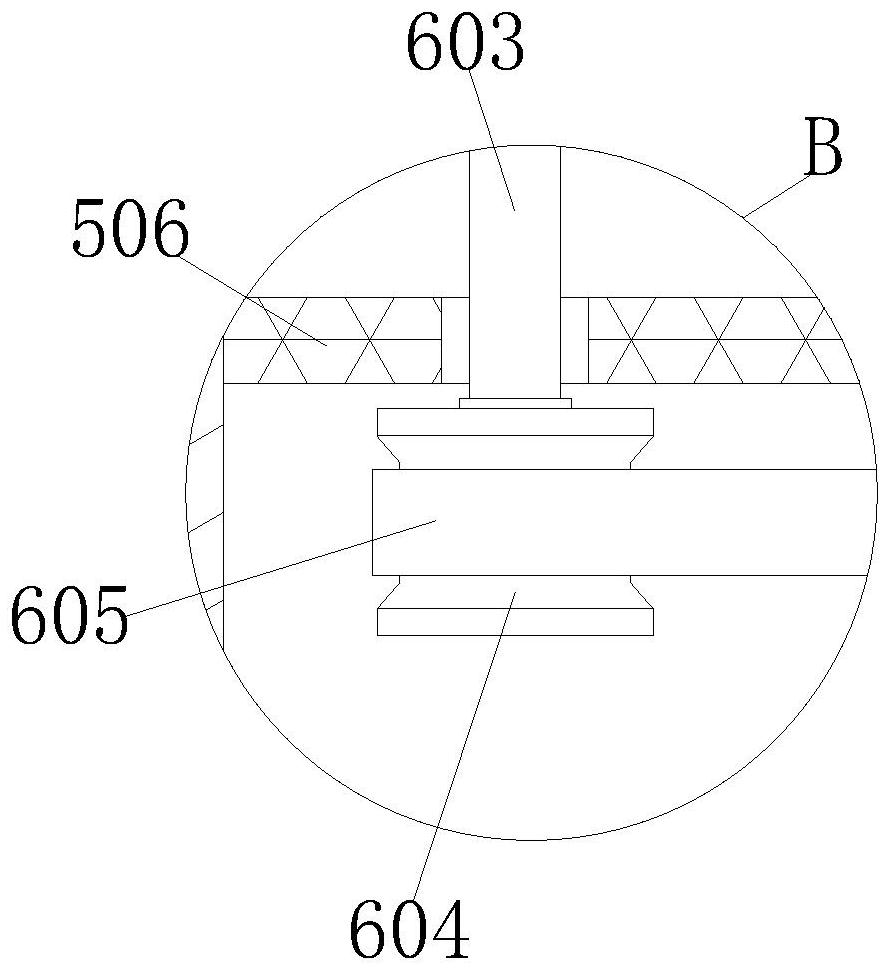

[0029] see Figure 1-7, the present invention provides a technical solution: a double twisting machine for processing man-made environmentally friendly fiber yarns, comprising a double twisting machine body 1, a dust suction mechanism 5 and a dust collection mechanism 6, and the top of the double twisting machine body 1 is fixedly installed by a fixing block There is a filter box 2, the front side of the filter box 2 is fixedly connected with an air inlet pipe and communicated with its interior, the dust suction mechanism 5 includes a rotating rod A502 and an induced fan blade 505 arranged inside the filter box 2, and one end of the three sets of rotating rods A502 Both are installed in rotation with the inner top of the filter box 2, the tops of the two sets of induced fan blades 505 are respectively fixedly connected with the other ends of the two sets of rotating rods A502, and the dust collecting mechanism 6 includes a pressure plate 601 arranged on one side of the filter b...

Embodiment 2

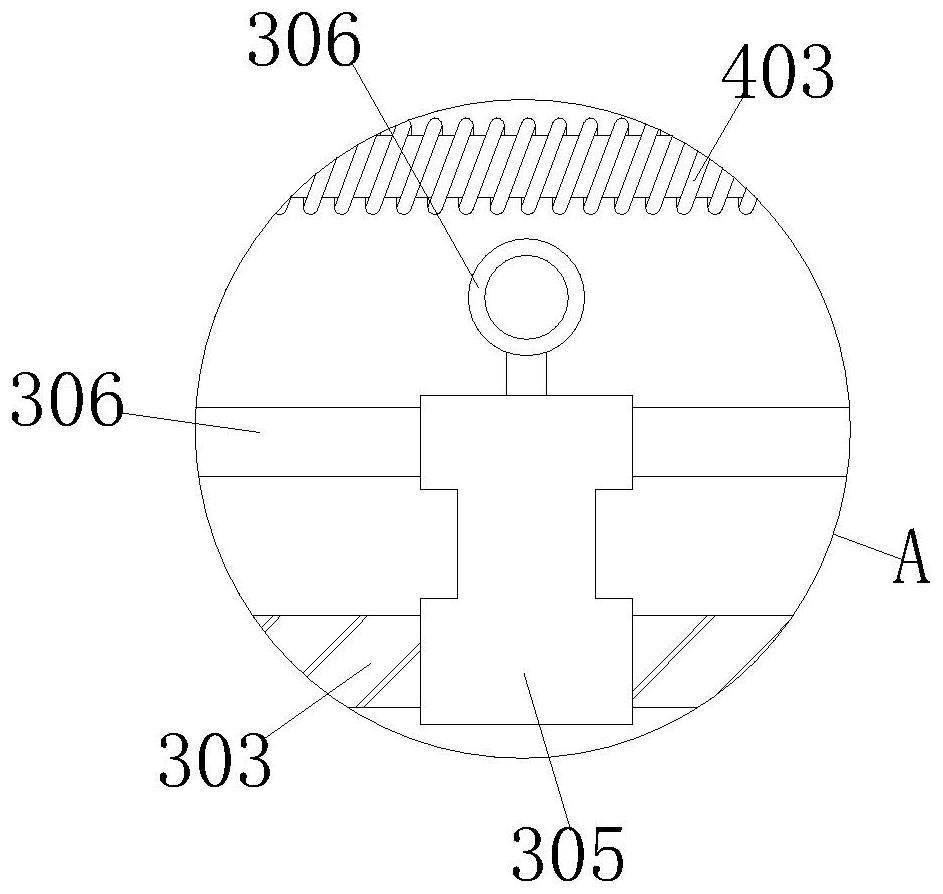

[0031] see Figure 1-7 , on the basis of the first embodiment, the thread-forming mechanism 3 includes an arcuate plate 301, a servo motor A302, a screw 303, a guide rod 304, a movable plate 305 and a thread head 306. One side of the inner wall is fixedly installed, one side of the outer wall of the servo motor A302 is fixedly installed with one side of the inner wall of the arcuate plate 301, one end of the screw 303 is rotated and installed on one side of the outer wall of the arcuate plate 301, and the output shaft of the servo motor A302 is extended through the coupling. One end of the guide rod 304 is fixedly connected to one side outer wall of the arcuate plate 301 and is fixedly connected to one side of the arcuate plate 301. The movable plate 305 is arranged on the outer wall of the screw 303 and the guide rod 304. The movable plate 305 There is a threaded groove matching the screw 303, the movable plate 305 is screwed with the screw 303, the movable plate 305 is slida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com