Deoxidation smelting method of slab Q235 steel and slab Q235 steel

A smelting method and slab technology, which are applied to the deoxidation smelting of slab Q235 steel and the field of slab Q235 steel, can solve the problems of rising occurrence rate of edge cracking of steel plates and waste of production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

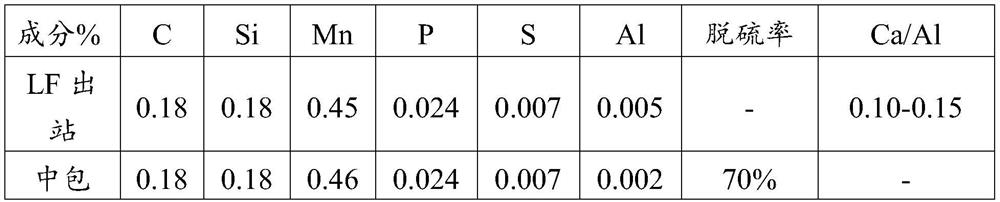

[0056] This embodiment provides a plate blank Q235 steel, which is obtained through the following methods:

[0057] S1: Carry out the smelting operation of the turntable, load 125T iron water and 35T scrap steel in the furnace, the total installation of iron and scrap steel is 160T, the amount of iron in the iron water is 825kg / T. And use the bottom -bottom re -blowing turntable blowing process to blow the bottom of the process;

[0058] S2: Load the slag, the slag includes 30kg of lime and 8kg of magnesium balls, and the amount of slag in the slag at the beginning of the blowing is 30 %. It

[0059] S3: Oxygen gun flow control at 33000M 3 / h; the gun position when the oxygen gun blows is 1.8m, and the static deputy grab TSC measures the carbon content of 0.35 %;

[0060] S4: Add manganese and silicon for steel deoxification alloy operation. The amount of manganese controls 0.40 % of the steel water, the amount of silicon is controlled by 0.20 % of the steel water, the carbon cont...

Embodiment 2

[0065] This embodiment provides a plate blank Q235 steel, which is obtained through the following methods:

[0066] S1: Carry out the smelting operation of the turntable, loads 126T iron water and 36T scrap steel in the furnace. And use the bottom -bottom re -blowing turntable blowing process to blow the bottom of the process;

[0067] S2: Load the slag, the slag includes 35kg of lime and 8kg of magnesium balls, and the amount of slag in the slag at the beginning of the blowing is 31 %, and the remaining 69 % of the slag is added within 4min after the blowing start. It

[0068] S3: Oxygen gun flow control at 33000M 3 / h; the gun position when the oxygen gun blows is 1.9m, and the static deputy grab TSC measures the carbon content of 0.37 %;

[0069] S4: Add manganese and silicon for steel deoxification alloy operation. The amount of manganese controls 0.42 % of steel water, the amount of silicon is controlled by 0.21 % of the steel water, the carbon content of the steel out of ste...

Embodiment 3

[0074] This embodiment provides a plate blank Q235 steel, which is obtained through the following methods:

[0075] S1: Carry out the smelting operation of the turntable, load 127T iron water and 37T scrap steel in the furnace, the total installation of iron and scrap steel is 164T, the amount of iron in the iron water is 827kg / T. And use the bottom -bottom re -blowing turntable blowing process to blow the bottom of the process;

[0076] S2: Load the slag, the slag includes 37kg of lime and 9kg of magnesium balls, and the amount of slag in the slag at the beginning of the blowing is 32 %. It

[0077]S3: Oxygen gun flow control at 34000M 3 / h; the gun position when the oxygen gun blows is 1.8m, and the static deputy grab TSC measures the carbon content of 0.38 %;

[0078] S4: Add manganese and silicon for steel deoxification alloy operation. The amount of manganese controls 0.44 % of steel water, the amount of silicon is controlled by 0.22 % of the steel water, the carbon content o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com