High-impact-resistance halogen-free flame-retardant polypropylene composite material and preparation method thereof

A technology of flame-retardant polypropylene and high impact resistance. It is applied in the field of high-impact-resistant halogen-free flame-retardant polypropylene composite materials and its preparation. It can solve the problems that the damping effect has not been improved and hinder the development of polypropylene materials, and achieve good damping. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

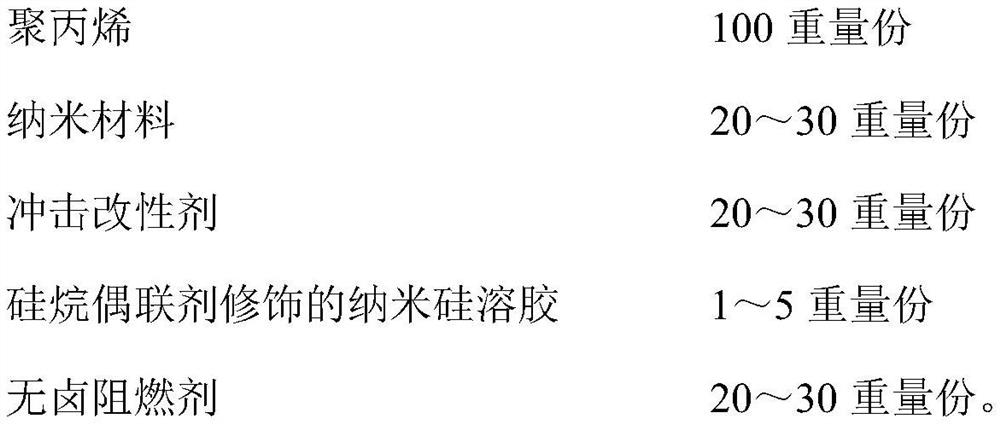

[0037] The high-impact halogen-free flame-retardant polypropylene composite material of this embodiment is prepared from the following components:

[0038]

[0039]

[0040] Wherein, polypropylene includes polypropylene I and polypropylene II, the mass ratio of polypropylene I and polypropylene II is 10:90, the polypropylene I is polypropylene with a melt index of 180 g / 10min, and the polypropylene II is Polypropylene with a melt index of 1300 g / 10min; the content of octene in POE is 35%.

[0041] The preparation method is as follows:

[0042] 1. Preparation of polypropylene particles

[0043] Polypropylene I with a melt index of 180 g / 10min and polypropylene II with a melt index of 1300 g / 10min are blended in a mass ratio of 10:90 and then granulated by twin-screw. acrylic pellets.

[0044] 2. Preparation of Silane Coupling Agent Modified Nano-Silica Sol

[0045]Mix the nano-silica sol with a solid content of 25% and a particle size of 20 nm with a γ-aminopropyl tri...

Embodiment 2

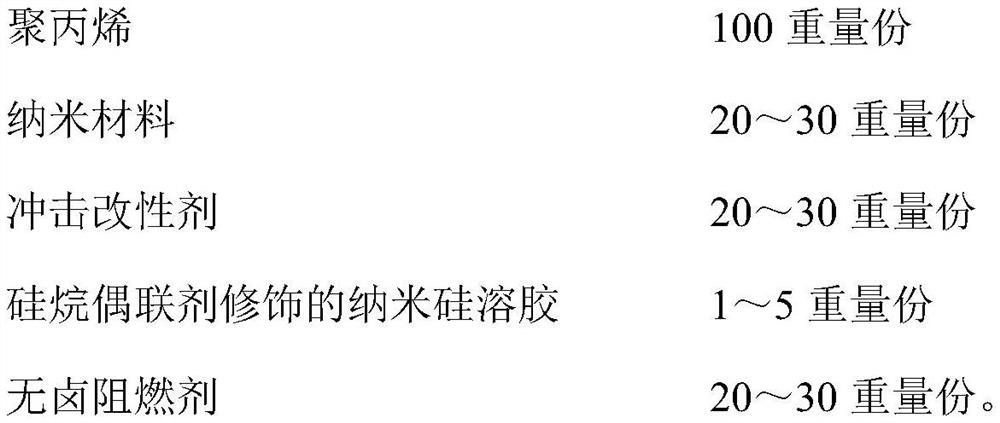

[0051] The high-impact halogen-free flame-retardant polypropylene composite material of this embodiment is prepared from the following components:

[0052]

[0053] Wherein, polypropylene includes polypropylene I and polypropylene II, the mass ratio of polypropylene I and polypropylene II is 90:10, the polypropylene I is polypropylene with a melt index of 350 g / 10min, and the polypropylene II is Polypropylene with a melt index of 1500 g / 10min; the content of octene in POE is 40%.

[0054] The preparation method is as follows:

[0055] 1. Preparation of polypropylene particles

[0056] Polypropylene I with a melt index of 350 g / 10min and polypropylene II with a melt index of 1500 g / 10min were blended at a mass ratio of 90:10 and then granulated by twin-screw. acrylic pellets.

[0057] 2. Preparation of Silane Coupling Agent Modified Nano-Silica Sol

[0058] Mix the nano-silica sol with a solid content of 35% and a particle size of 40 nm and a γ-aminopropyl triethoxysilan...

Embodiment 3

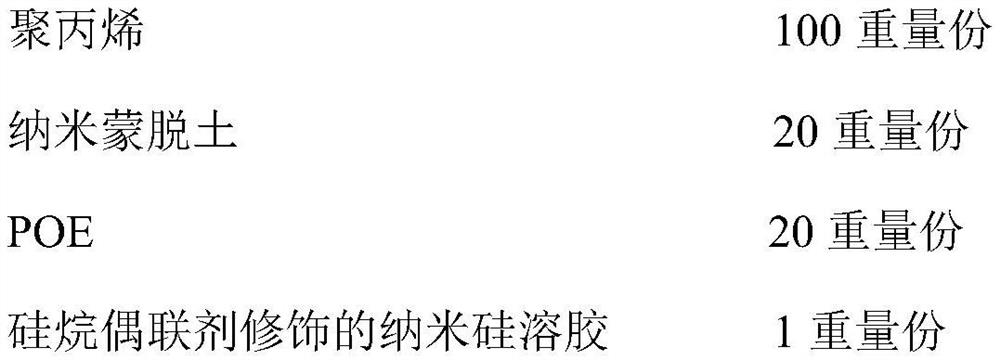

[0064] The high-impact halogen-free flame-retardant polypropylene composite material of this embodiment is prepared from the following components:

[0065]

[0066] Wherein, polypropylene includes polypropylene I and polypropylene II, the mass ratio of polypropylene I and polypropylene II is 50:50, the polypropylene I is polypropylene with a melt index of 200 g / 10min, and the polypropylene II is Polypropylene with a melt index of 1400 g / 10min; the content of octene in POE is 38%.

[0067] The preparation method is as follows:

[0068] 1. Preparation of polypropylene particles

[0069] Polypropylene I with a melt index of 200 g / 10min and polypropylene II with a melt index of 1400 g / 10min are blended in a mass ratio of 50:50 and then granulated by twin-screw, and the temperature of the screw is controlled at 130 ℃ ~ 155 ℃ for granulation to obtain a polymer. acrylic pellets.

[0070] 2. Preparation of Silane Coupling Agent Modified Nano-Silica Sol

[0071] Mix the nano-si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com