Continuous flow low-carbon denitrification process for low-carbon-nitrogen-ratio domestic sewage

A low-carbon-to-nitrogen ratio, domestic sewage technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc. Sewage water temperature, stability, high requirements for automatic control, etc., to achieve the effect of easy engineering use and efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with specific embodiments.

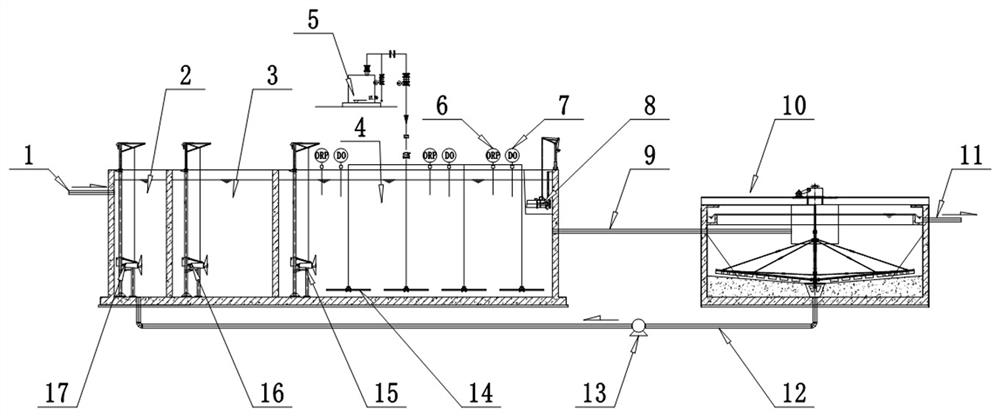

[0027] like figure 1 , A treatment system for implementing the continuous flow low-carbon denitrification process of the present invention includes two pools, the first being a biological reaction pool and the second being a secondary sedimentation pool 10 . The biological reaction tank is divided into three grids, which are the anaerobic tank 2 as the A pool, the anoxic pool 3 as the A pool and the aerobic pool 4 as the O pool. The aerobic tank 4 is connected with the secondary sedimentation tank 10 through the transition pipe 9 . Phosphorus-accumulating bacteria in anaerobic tank 2 release phosphorus; in aerobic tank 4, mineralization of organic pollutants and nitrification and nitrification of ammonia nitrogen occur and excessive phosphorus intake; in anoxic tank 3, denitrification of nitrate nitrogen occurs, and converted into nitrogen. The secondary sedimentation tank 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com