Bismuth titanate niobate nanosheet based on self-doping regulation and control of crystal face exposure and preparation method of bismuth titanate niobate nanosheet

A technology of self-doping and titanium niobic acid, applied in the field of photocatalysis, can solve the problems of complex crystal plane regulation and other problems, and achieve the effects of excellent photodegradation efficiency, efficient photodegradation of organic pollutants, and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

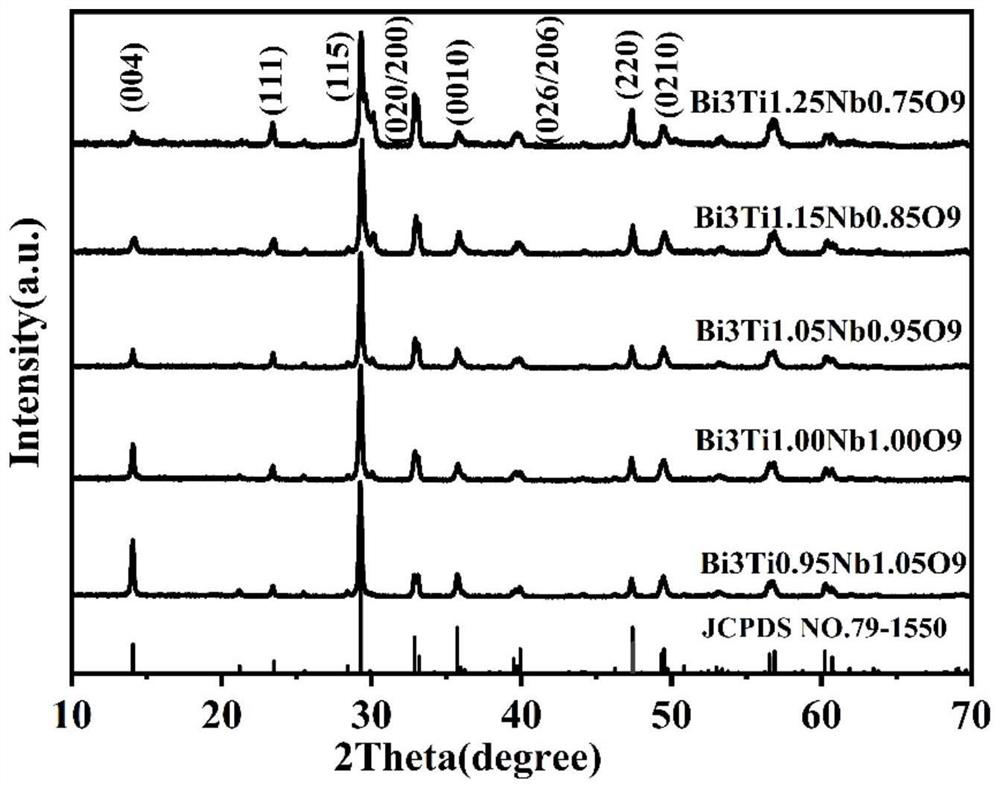

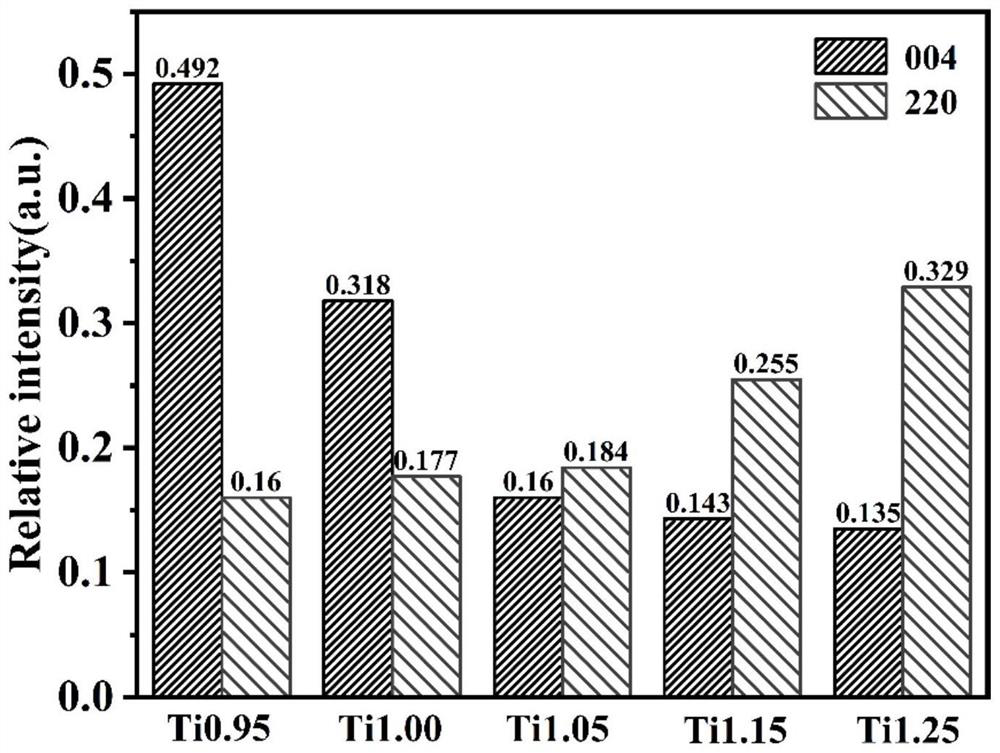

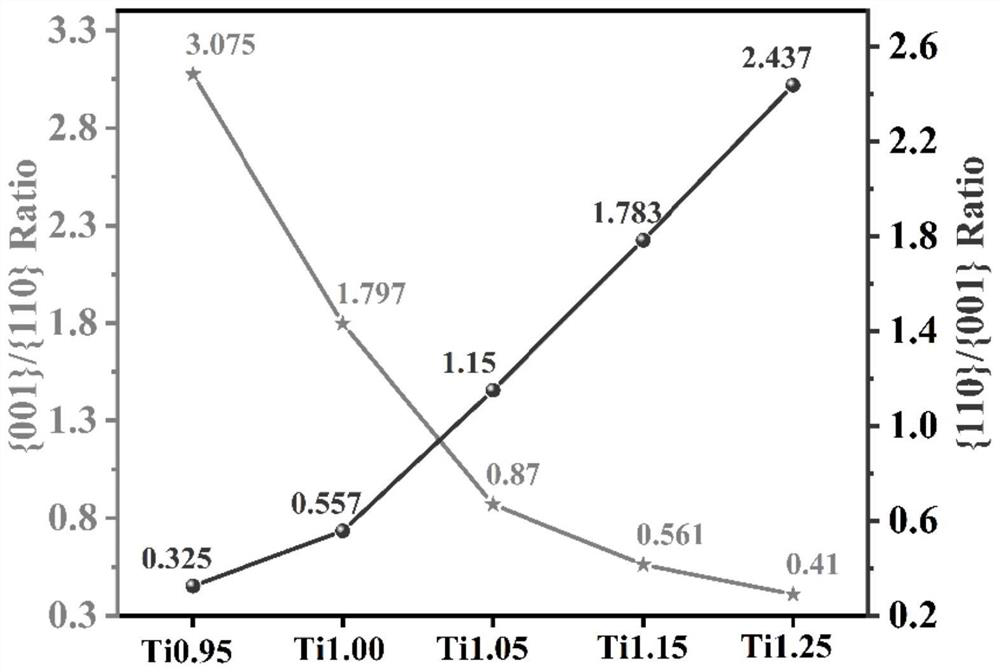

[0029] A preparation method of bismuth titanium niobate nanosheets based on self-doping regulation of crystal plane exposure, comprising the following steps:

[0030] Step 1: Put Bi 2 O 3 , TiO 2 , Nb 2 O 5 And the salt compound is uniformly mixed by ball milling and dried to obtain a mixed powder;

[0031] Step 2: After calcining the mixed powder in Step 1, a massive solid is obtained, and after washing and drying, the bismuth titanate niobate nanosheets whose crystal planes are exposed by self-doping control are obtained.

[0032] The salt compounds are NaCl and KCl.

[0033] In described step 1, NaCl, KCl, Bi 3 Ti x Nb 2-x O 9 The molar ratio is 50:50:1.

[0034] In the step 1, Bi 2 O 3 , TiO 2 with Bi 3 Ti x Nb 2-x O 9 The molar ratio is 1.5:(0.95-1.25):(0.375-0.525);

[0035] In the described step 1, the ball milling conditions are specifically: the analytically pure Bi 2 O 3 , TiO 2 , Nb 2 O 5 , the salt compound was mixed with 100g of zirconite an...

Embodiment 1

[0047] The self-doped Bi 3 TiNbO 9 Nanosheets, chemical formula Bi 3 Ti x Nb 2-x O 9 , where x=0.95, where x represents the mole percent.

[0048] Preparation of Bi by one-step molten salt method 3 Ti x Nb 2-x O 9 , where x=0.95, including the following steps:

[0049] Step 1: According to the chemical formula Bi 3 Ti x Nb 2-x O 9 (x=0.95), 1.3978g Bi 2 O 3 , 0.1518g TiO 2 , 0.2791g Nb 2 O 5 , 5.844g NaCl, 7.455g KCl, and 25mL absolute ethanol were mixed uniformly by mechanical ball milling for 5h, and then the dried powder was calcined in a muffle furnace, heated to 850°C at 10°C / min, and the holding time was 3h. Cool down to 400°C at 10°C / min, and cool to room temperature with the furnace;

[0050] Step 2: Put the bulk solid in deionized water at 50°C, stir and wash, change the water every 2 hours, wash until there is no white precipitate in the supernatant with silver nitrate, and then dry at 60°C for 16 hours.

Embodiment 2

[0052] The self-doped Bi 3 TiNbO 9 Nanosheets, chemical formula Bi 3 Ti x Nb 2-x O 9 , where x=1.05, where x represents mole percent.

[0053] Preparation of Bi by one-step molten salt method 3 Ti x Nb 2-x O 9 , where x=1.05, including the following steps:

[0054] Step 1: According to the chemical formula Bi 3 Ti x Nb 2-x O 9 (x=1.05), 1.3978g Bi 2 O 3 , 0.1677g TiO 2 , 0.2525g Nb 2 O 5 , 5.844g NaCl, 7.455g KCl, and 25mL absolute ethanol were mixed uniformly by mechanical ball milling for 5h, and then the dried powder was calcined in a muffle furnace, heated to 850°C at 10°C / min, and the holding time was 3h. Cool down to 400°C at 10°C / min, and cool to room temperature with the furnace;

[0055] Step 2: Put the bulk solid in deionized water at 60°C, stir and wash, change the water every 1.5h, wash until there is no white precipitate in the supernatant with silver nitrate, and then dry at 70°C for 12h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com