Bidirectional stretching multifunctional mechanism of high-heat-sealing-strength anti-fog film

A biaxial stretching and multi-functional technology, applied in the direction of climate change adaptation, etc., can solve the problems of reducing the scope of application, affecting the quality of the film, unable to adjust the length of the transverse stretching of the film, etc., to achieve the effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

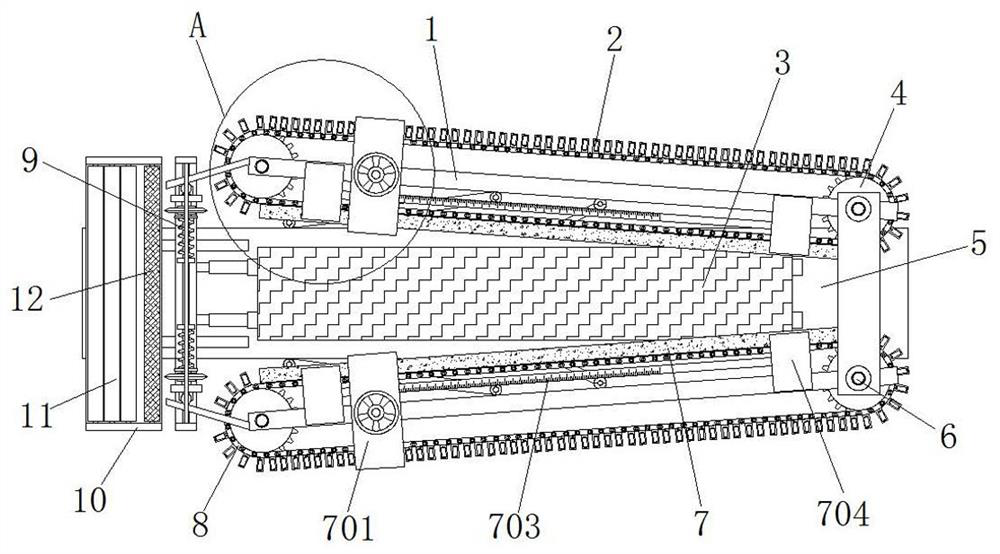

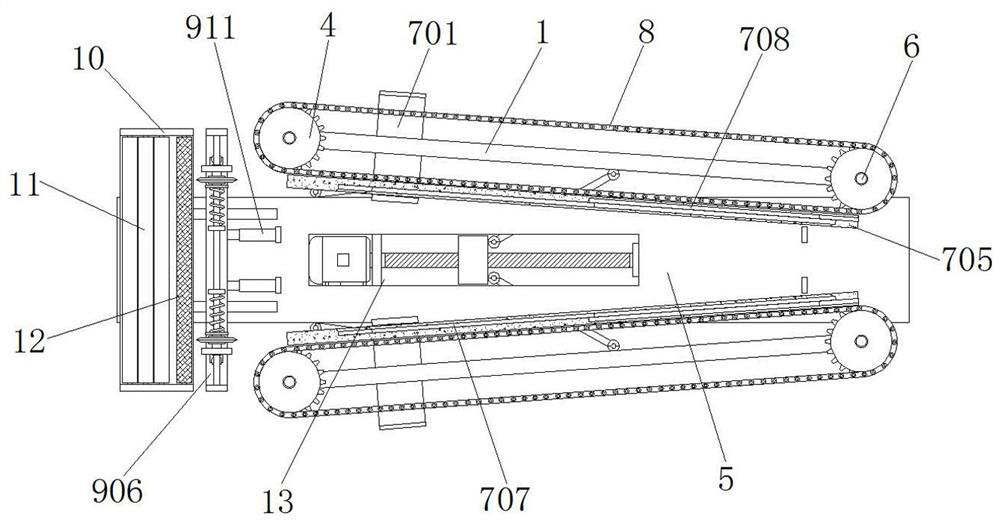

[0041] Example 1, as Figure 1-3 As shown in and 5, a trapezoidal plate is symmetrically installed at one end of the mounting table 5 away from the second U-shaped frame 10, and the tops of the two sets of trapezoidal plates are symmetrically installed with fixed bearings, while the two groups away from the second U-shaped frame 10 are installed symmetrically. The bottom of the outer side of the rotating rod 6 is respectively fixedly connected with the inner side of the adjacent set of fixed bearings, the driving motor of the driving device 14 is located below the trapezoidal plate, and the first pulley and the second pulley are located above the mounting table 5, that is, the trapezoidal plate , while the two sets of drive gears are located below the mounting table 5 .

Embodiment 2

[0042] Example 2, as Figure 1-11 As shown, when it is necessary to adjust the width of the film edge material cut by the annular cutter 905, the two sets of movable frames 701 are manually moved on the installation frame 1, and the installation frame 1 is moving away from the second U-shaped frame 10. , the mounting frame 1 drives the sliding block 706 to slide inside the sliding groove 709, and the sliding block 706 drives the movable guide bar 707 to move, which will advance the separation time relative to the two sets of splints 201, thereby adjusting the high heat-sealing strength anti-fog film The stretched width and time, when the width of the high heat-sealing strength anti-fogging film is reduced, the width of the film edge cut by the annular cutter 905 is correspondingly shortened, thereby reducing the waste of film materials.

Embodiment 3

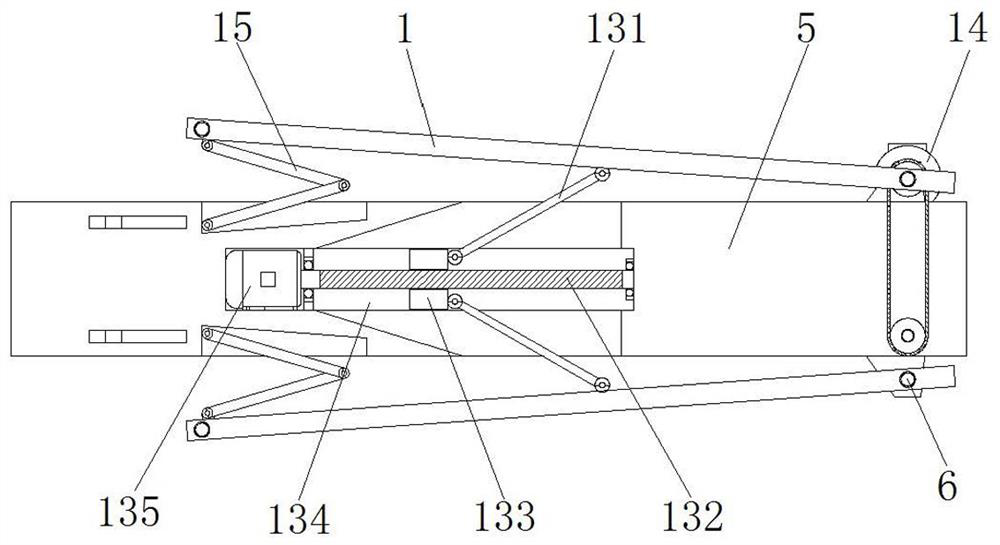

[0043] Example 3, as Figure 1-3 As shown in the figure, when it is necessary to adjust the transverse stretching width of the high heat-sealing strength anti-fog film, the servo motor 135 is controlled to drive the long threaded rod 132 to rotate, and the internal threaded pipe 133 is forced to move on the outside of the long threaded rod 132 by the thread action, thereby driving the first threaded rod 132. A hinge rod 131 pushes one end of the mounting frame 1 to move, so that the two sets of mounting frames 1 are opened or tightened with their hinge shaft as the axis, and the angle between the two sets of mounting frames 1 and the mounting table 5 is adjusted. The width of the high heat-sealing strength anti-fog film stretched laterally is adjusted, and when the device is not in use, the rotation of the servo motor 135 can also be controlled to make the two sets of mounting brackets 1 approach both sides of the mounting table 5, thereby reducing the overall The space occupi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com