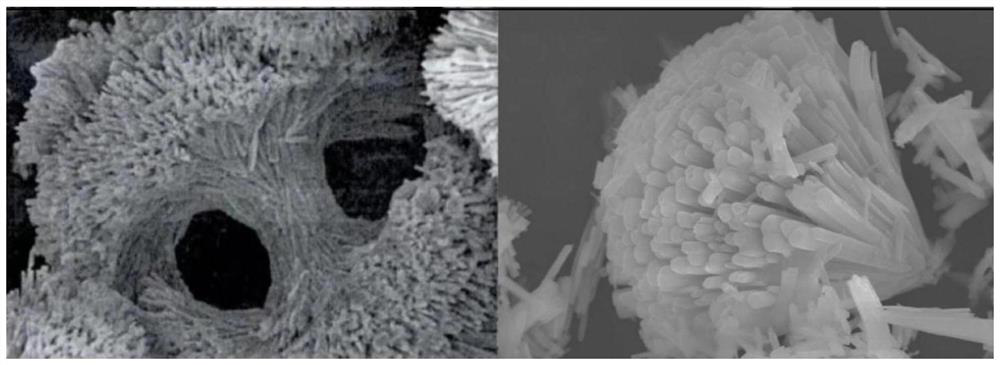

Cauliflower-shaped LaMnO3-CuMnCeOx mixed composite oxide catalyst, preparation method and application of cauliflower-shaped LaMnO3-CuMnCeOx mixed composite oxide catalyst

A composite oxide, cauliflower-like technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve chlorine-containing by-products, easy sintering, loss, etc. problem, to achieve the effect of efficient and stable adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

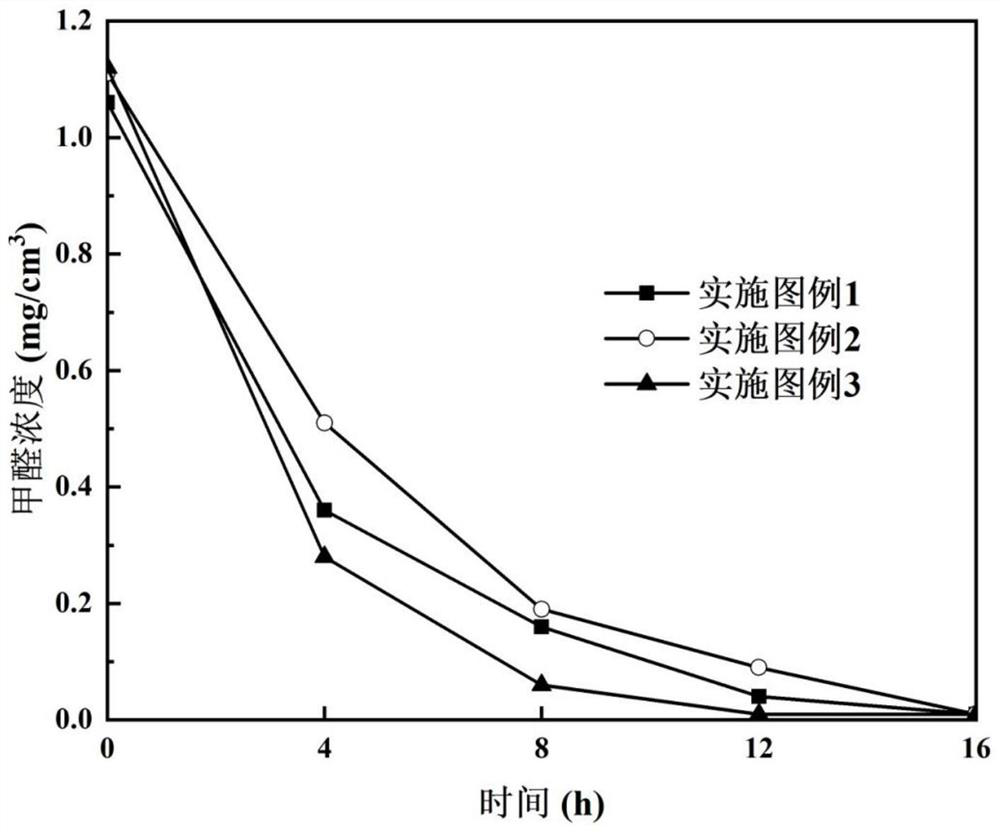

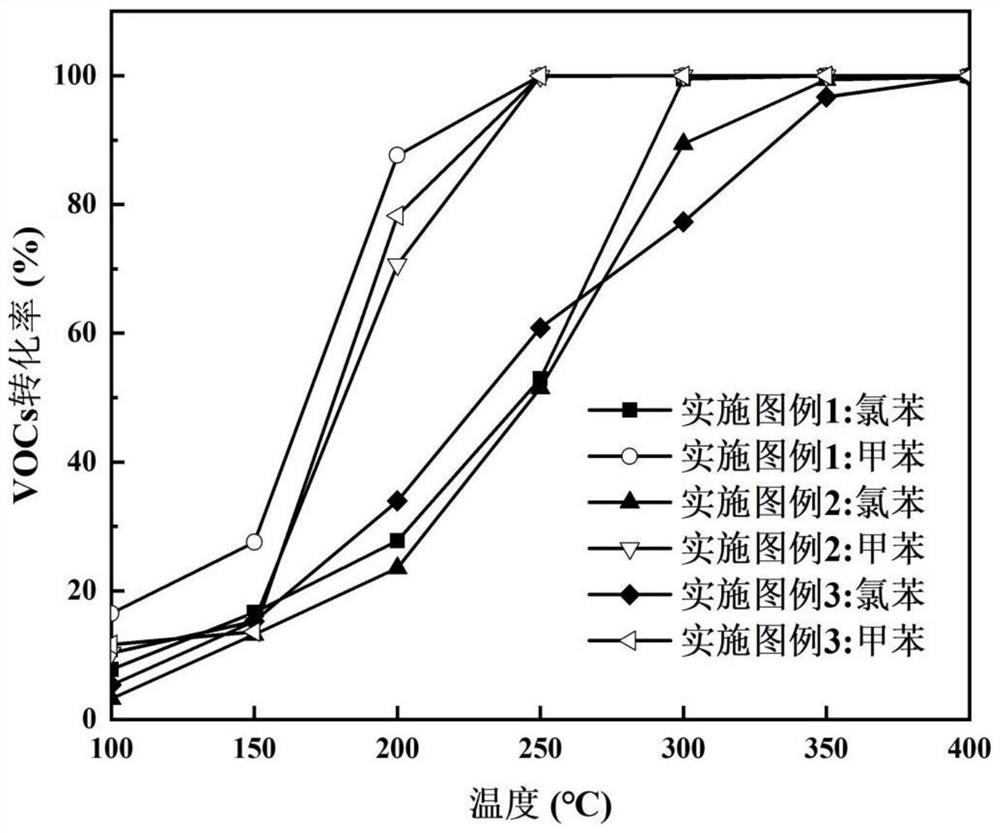

Embodiment 1

[0033] Cauliflower LaMnO 3 -CuMnCeO x The specific steps for the preparation of the mixed composite oxide catalyst are as follows:

[0034] Step 1, Preparation of cauliflower-like LaMnO 3 -CuMnCeO x mixed oxides;

[0035] Take an appropriate amount of solid lanthanum nitrate, manganese nitrate solution and deionized water, stir until completely dissolved to form mixed solution A, wherein the molar ratio of La to Mn is 1:1; then take appropriate amount of solid cerium nitrate, copper nitrate, manganese nitrate solution and deionized Ionized water, stir until completely dissolved to form mixed solution B, wherein the molar ratio of Cu to Mn and Ce is 2:5:2; then mix mixed solution A and solution B, and add an appropriate amount of trisodium citrate and stir until completely dissolved, Then add 0.1mol / L sodium hydroxide solution dropwise until the pH is 12, then mix and stir for 30min, wherein LaMnO 3 with CuMnCeO x The molar ratio was 1:3; then the above solution was place...

Embodiment 2

[0039] Cauliflower LaMnO 3 -CuMnCeO x The specific steps for the preparation of mixed composite oxide catalysts are as follows

[0040] Step 1, Preparation of cauliflower-like LaMnO 3 -CuMnCeO x mixed oxides;

[0041] Take an appropriate amount of solid lanthanum nitrate, manganese nitrate solution and deionized water, stir until completely dissolved to form mixed solution A, wherein the molar ratio of La to Mn is 1:1; then take appropriate amount of solid cerium nitrate, copper nitrate, manganese nitrate solution and deionized Ionized water, stir until completely dissolved to form mixed solution B, wherein the molar ratio of Cu to Mn and Ce is 2:5:2; then mix mixed solution A and solution B, and add an appropriate amount of trisodium citrate and stir until completely dissolved, Then add 0.1mol / L sodium hydroxide solution dropwise until the pH is 12, then mix and stir for 30min, wherein LaMnO 3 with CuMnCeO x The molar ratio was 1:1; then the above solution was placed in...

Embodiment 3

[0045] Cauliflower LaMnO 3 -CuMnCeO x The specific steps for the preparation of mixed composite oxide catalysts are as follows

[0046] Step 1, Preparation of cauliflower-like LaMnO 3 -CuMnCeO x mixed oxides;

[0047] Take an appropriate amount of solid lanthanum nitrate, manganese nitrate solution and deionized water, stir until completely dissolved to form mixed solution A, wherein the molar ratio of La to Mn is 1:1; then take appropriate amount of solid cerium nitrate, copper nitrate, manganese nitrate solution and deionized Ionized water, stir until completely dissolved to form mixed solution B, wherein the molar ratio of Cu to Mn and Ce is 2:5:2; then mix mixed solution A and solution B, and add an appropriate amount of trisodium citrate and stir until completely dissolved, Then add 0.1mol / L sodium hydroxide solution dropwise until the pH is 12, then mix and stir for 30min, wherein LaMnO 3 with CuMnCeO x The molar ratio was 3:1; then the above solution was placed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com