Industrial environment-friendly movable welding fume purification device

A purification device and mobile technology, applied in the fields of human health protection, climate change adaptation, chemical instruments and methods, etc., can solve the problems of damage to the universal vacuuming arm, troublesome cleaning, insufficient suction of the dust removal motor, etc., and prolong the service life. , the effect of avoiding gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

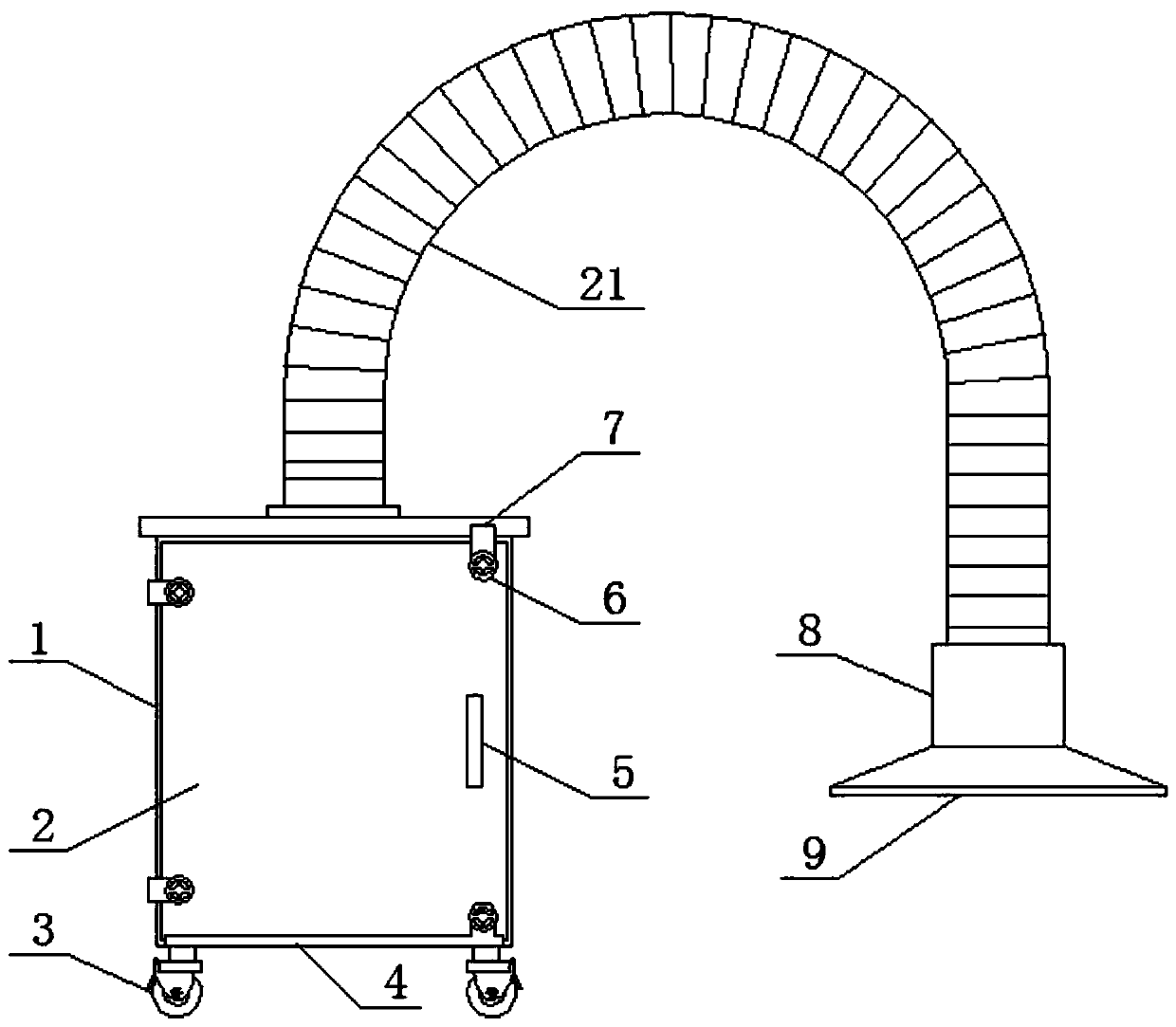

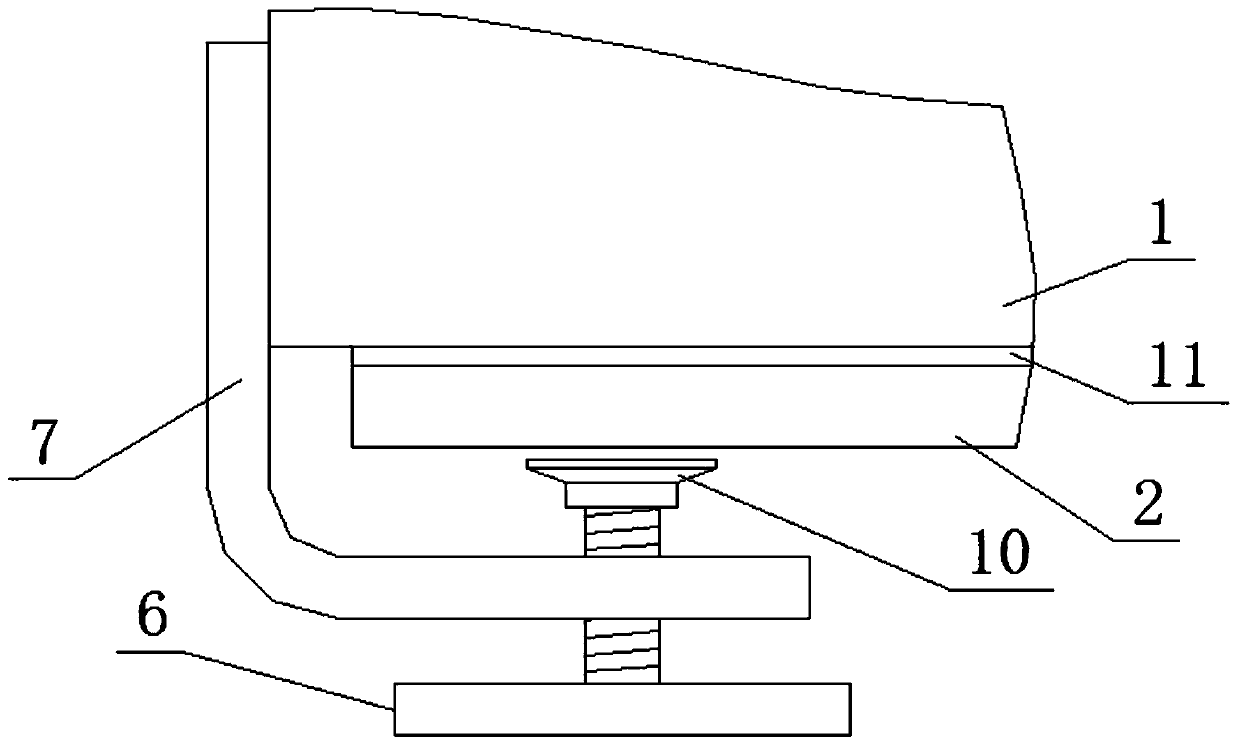

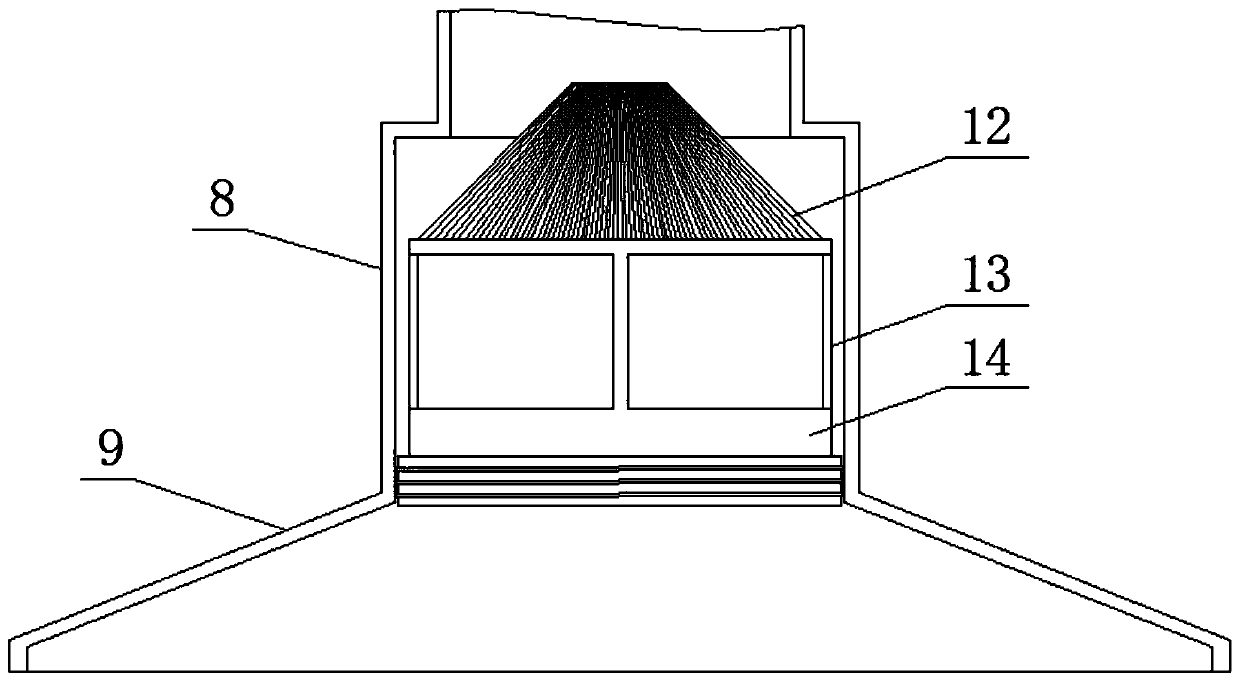

[0021] see Figure 1-Figure 7 , the present invention provides the following technical solutions: an industrial environment-friendly mobile welding fume purification device, comprising a fume purifier outer shell 1, the bottom end of the fume dust purifier outer shell 1 is provided with a door chute 4, and the fume dust purifier shell The position of the body 1 corresponding to the door chute 4 is engaged with the door 2 of the air purification room, and the four tops of the outer body 1 of the smoke and dust purifier corresponding to the door 2 of the air purification room are fixed with door sealing clamps 7, and the smoke and dust purification The top of the outer casing 1 is fixed with a universal dust suction arm 21, one side of the door sealing clamp 7 is bolted with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com