A kind of polyaluminum chloride phosphorus removal filler and preparation method thereof

A technology of polyaluminum chloride and polyaluminum chloride, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of losing the phosphorus removal function, and achieve fast sedimentation and adsorption Efficient and stable performance, efficient and stable purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

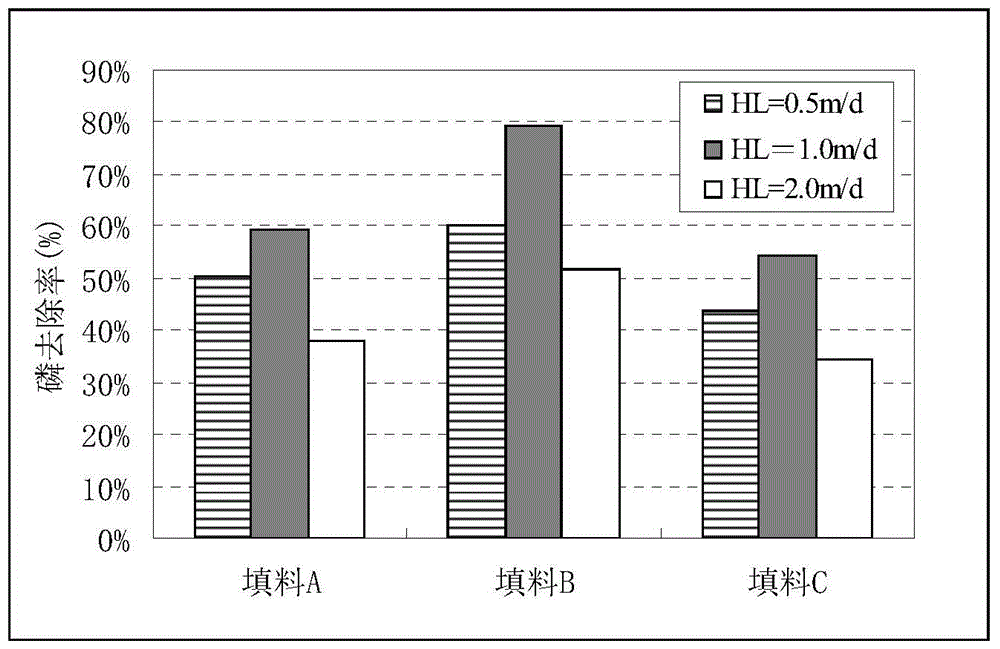

[0025] Embodiment 1 Phosphorus removal filler treatment effect of eutrophication landscape water

[0026] After mixing and stirring polyaluminum chloride (PAC), high-grade cement, construction glue and water according to the ratio (weight ratio) in Table 1, press it into solid particles with a particle size of 1.0-3.0cm under a pressure of 0.3-0.5MPa , and dried to obtain the finished product of filling.

[0027] Raw material ratio table (weight ratio) used for three kinds of filler products in table 1

[0028]

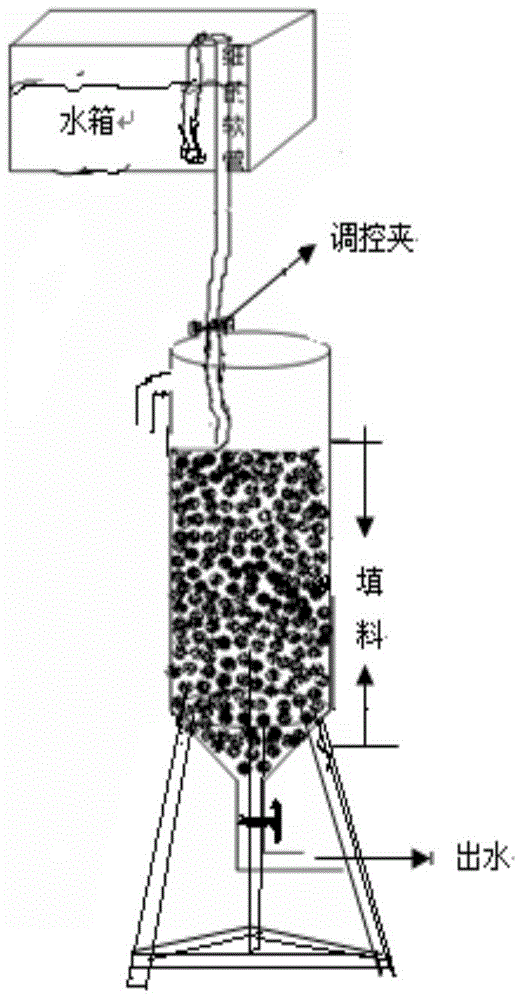

[0029] The structure of the test device is as figure 1 As shown, it includes: high-level water tank (effective volume 25L), column filled with phosphorus removal packing (filling height is 50cm, diameter is 9cm); water inlet hose, spring clip for controlling flow. Hydraulic load is an important factor affecting the process effect. This case studies the phosphorus removal effect of different fillers under different hydraulic loads. Three hydraulic loads are design...

Embodiment 2

[0032] Embodiment 2 Phosphorus removal filler treatment effect of domestic sewage

[0033]Mix and stir polyaluminum chloride (PAC), high-grade cement, construction glue and water according to the proportions in Table 1 (weight ratio), press them into solid particles with a particle size of 1.0-3.0 cm, and dry them to obtain finished fillers.

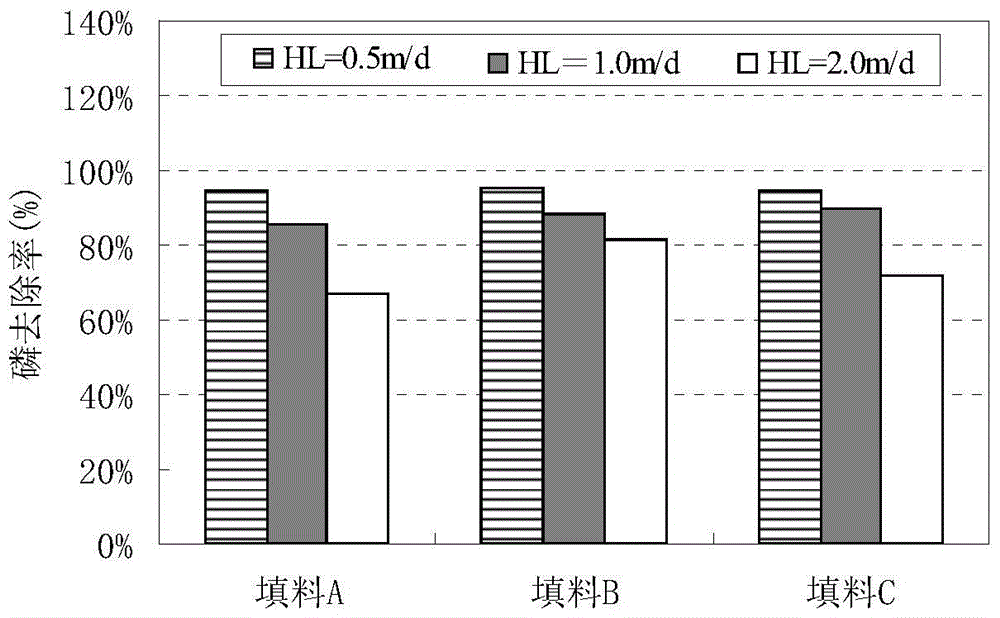

[0034] The structure of the test device is as figure 1 As shown, it includes: high-level water tank (effective volume 25L), column filled with phosphorus removal packing (filling height is 50cm, diameter is 9cm); water inlet hose, spring clip for controlling flow. Hydraulic load is an important factor affecting the process effect. This case studies the phosphorus removal effect of different fillers under different hydraulic loads. Three hydraulic loads are designed respectively, 0.5m 3 / m 2 d -1 , 1.0m 3 / m 2 d -1 , 2.0m 3 / m 2 d -1 , the corresponding water flow rates are: 3.25L / d, 6.5L / d and 13L / d.

[0035] image 3 It is a ...

Embodiment 3

[0037] Example 3 Comparison of newly developed filler and common volcanic rock filler for domestic sewage treatment

[0038] Polyaluminum chloride (PAC), high-grade cement, construction glue and water are mixed and stirred according to the proportion of filler B in Table 1 (weight ratio), and then pressed into solid particles with a particle size of 1.0 to 3.0 cm, and dried to obtain the filler finished product.

[0039] When the concentration of total phosphorus in the influent is 2.8-3.2mg / L (average value 2.9mg / L), the newly developed filler B can withstand a hydraulic load of 0.5m 3 / m 2 d -1 The removal efficiency of phosphorus is the best, with an average removal rate of 95.29%, and the average concentration of total phosphorus in the effluent water is 0.17mg / L, which meets the Class III water standard of "Environmental Quality Standards for Surface Water" (GB3838-2002).

[0040] When the total phosphorus concentration of the influent is 2.8-3.2mg / L (average value 2.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com