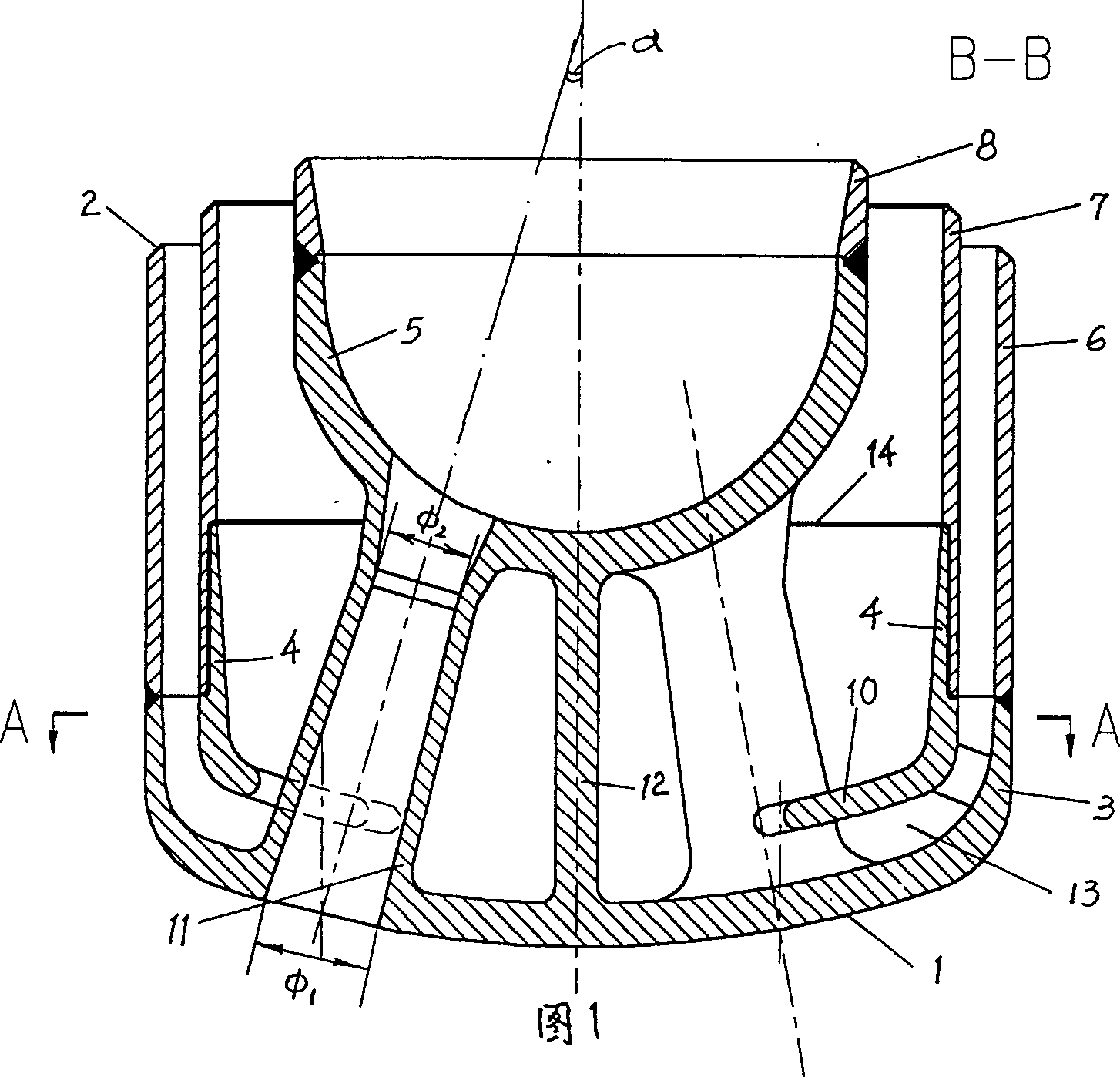

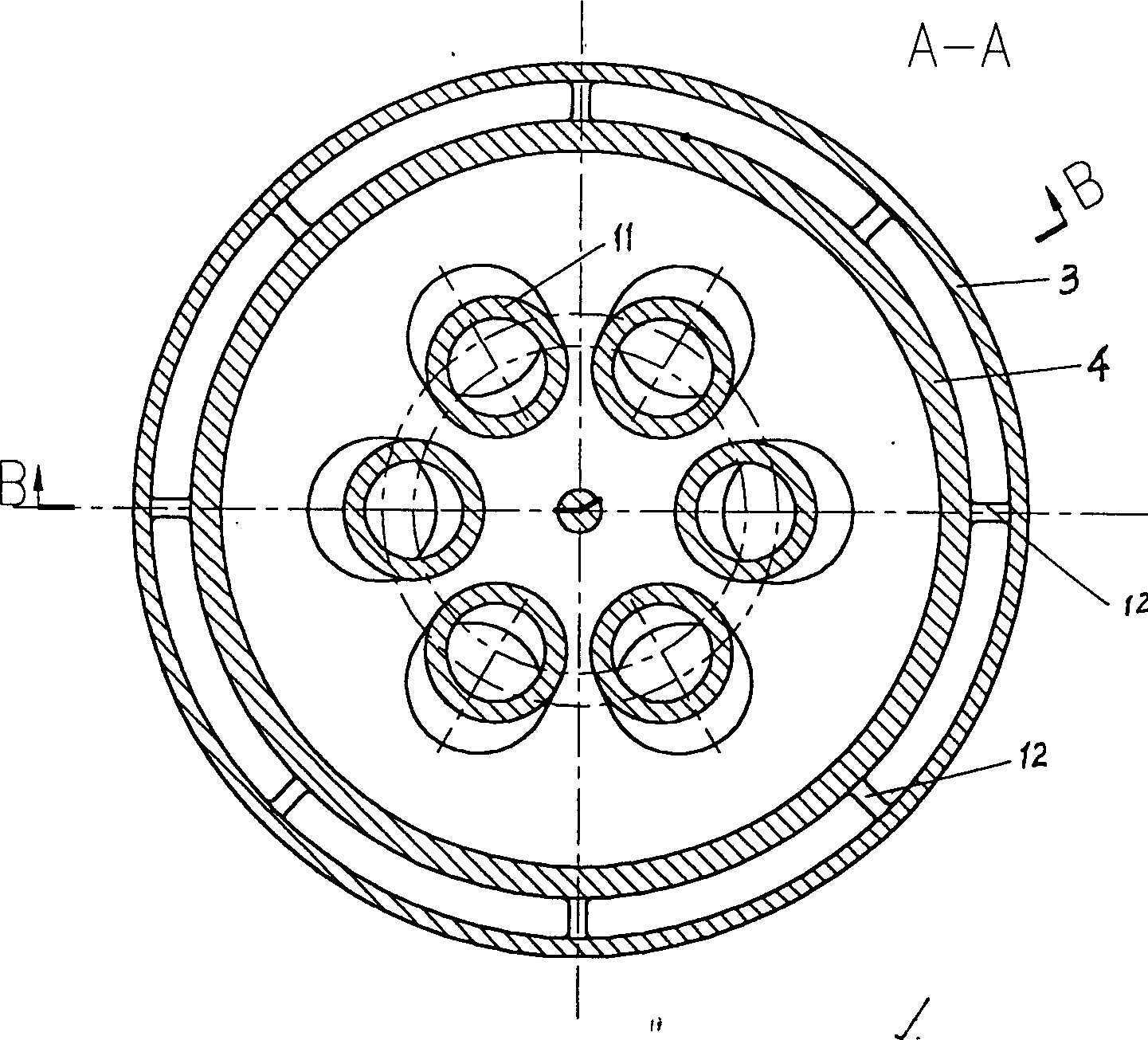

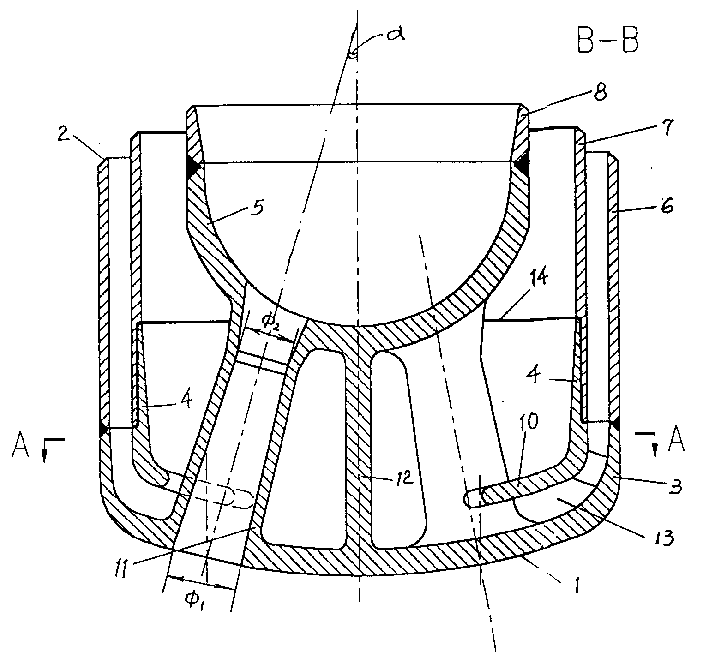

Spraygun for splashing slags to protect converter and its splashing method

A technology of slag splashing to protect the furnace and spray gun, which is applied in the manufacture of converters, etc., can solve the problems of jet flow properties that cannot meet the requirements of slag splashing to protect the furnace, short service life of the steelmaking oxygen lance, and the influence of slag hanging uniformity, etc., to shorten the splashing Time, nozzle design is reasonable, the effect of saving nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Using the converter slag splashing protection spray gun and the spraying method thereof according to the present invention, three furnace slag splashing protection tests were carried out on a 300 ton converter. The relevant structural parameters of the spray gun used in the test are shown in Table 1. 3. After the furnace steel is tapped, some residual slag remains, the spray gun of the present invention is inserted into the furnace for positioning, the slag adjusting material is added into the furnace, and then nitrogen gas is blown to splash the slag.

[0032] In each furnace test, the amount of final slag, the composition and amount of the added investigation material, the nitrogen consumption, the height of the gun position and the time of splashing are shown in Table 2. The composition of the final slag, the thickness of the slag splash layer, the consumption of lining bricks, the consumption of repairing materials and the operating rate of the converter are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com