Preparation and application of ultrathin organic-inorganic composite solid electrolyte membrane

A technology of solid electrolyte membrane and solid electrolyte, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of unmatched positive electrode materials, low battery power density, narrow electrochemical window, etc., and achieve good electrochemical performance, good Flexibility and machinability, effects of high room temperature ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

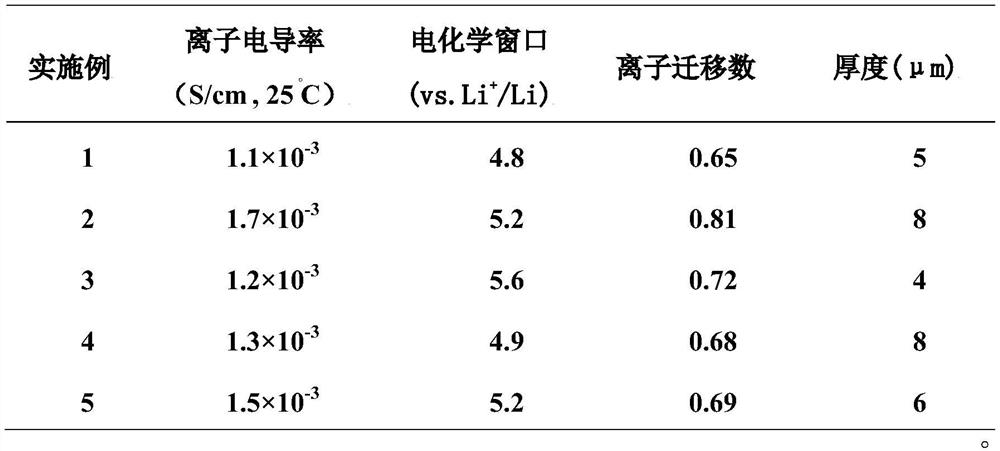

Embodiment 1

[0025] First, 1 g of polyvinylidene fluoride (PVDF) was dispersed and dissolved in NMP organic solvent, fully stirred and completely dissolved, and the same amount of garnet-type Li as PVDF was added. 6.6 La 2.9 Ca 0.1 Zr 1.75 W 0.25 O 12The solid electrolyte nanoparticles were vigorously stirred for 12h and sonicated for 2h to obtain a slurry with uniform particle dispersion. An ultra-thin composite electrolyte base film was prepared by the casting method to obtain a thin film electrolyte base film; then polyethylene ethylene carbonate with high ionic conductivity was selected. The electrolyte precursor solution (ethylene ethylene carbonate (76%) + LiTFSI (23.99%) + azobisisobutyronitrile (0.01%)) was poured into the thin-film electrolyte base membrane by solution casting, and the High temperature curing yields ultrathin organic-inorganic composite electrolyte membranes with excellent properties.

Embodiment 2

[0027] First, 1 g of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) was dispersed and dissolved in NMP organic solvent, fully stirred and completely dissolved, and the same amount of garnet-type Li as PVDF-HFP was added. 6.6 La 2.9 Ca 0.1 Zr 1.75 W 0.25 O 12 The solid electrolyte nanoparticles were vigorously stirred for 12 hours and ultrasonicated for 2 hours to obtain a slurry with uniform particle dispersion. The ultra-thin composite electrolyte base film was prepared by the casting method to obtain a thin film electrolyte base film; then a high-ionic polyethylene carbonate electrolyte precursor solution was selected. (ethylene ethylene carbonate (76%) + LiTFSI (23.99%) + azobisisobutyronitrile (0.01%)), poured into the thin film electrolyte base membrane by solution casting method, and cured at 80 °C to obtain a Ultrathin organic-inorganic composite electrolyte membrane with excellent performance.

Embodiment 3

[0029] First, 1 g of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) was dispersed and dissolved in NMP organic solvent, fully stirred and completely dissolved, and the same amount of silica nanoparticles as PVDF-HFP was added, stirred vigorously for 12 hours, and ultrasonicated for 2 hours to obtain particles The uniformly dispersed slurry was prepared by casting method to obtain an ultra-thin composite electrolyte base film to obtain a thin film electrolyte base film; Polyethylene carbonate electrolyte precursor solution (ethylene ethylene carbonate (76%) + LiTFSI (23.99%) + azobisisobutyronitrile (0.01%)), poured into the thin-film electrolyte base membrane by solution casting method, and cured at high temperature to obtain an ultra-thin organic-inorganic composite electrolyte membrane with excellent performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com