Thermal response silane coupling agent and preparation method thereof

A silane coupling agent and heat-responsive technology, which is applied in the field of heat-responsive silane coupling agent and its preparation, can solve the problems of inflammation and side effects, biological safety cannot be solved, and achieve the treatment of bacterial infection, superior thermal degradation and Bactericidal effect, the effect of simple operation of the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

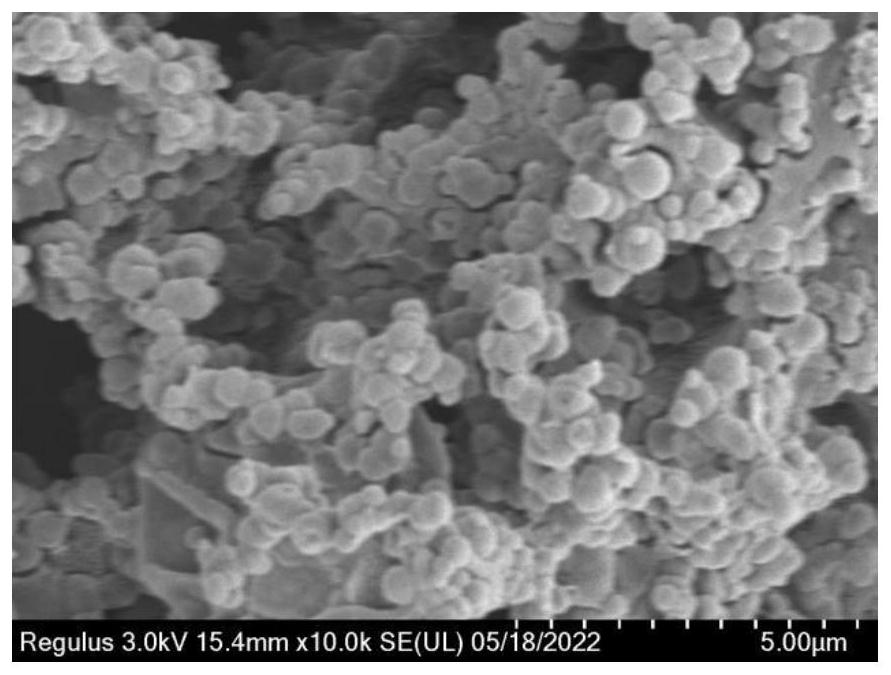

Examples

preparation example Construction

[0038] A preparation method of a thermally responsive silane coupling agent, comprising the following steps:

[0039] (1) Dissolve the azo initiator and triethylamine in the organic reagent and add it to the three-necked flask, then add dropwise acryloyl chloride dissolved in the organic reagent, and stir the reaction in an ice-water bath for 12 to 24 hours. The reaction needs to be carried out under the protection of a nitrogen atmosphere; After the reaction, the solution is washed with alkali to remove unreacted substances, concentrated and purified, and recrystallized to obtain an acylated azo initiator,

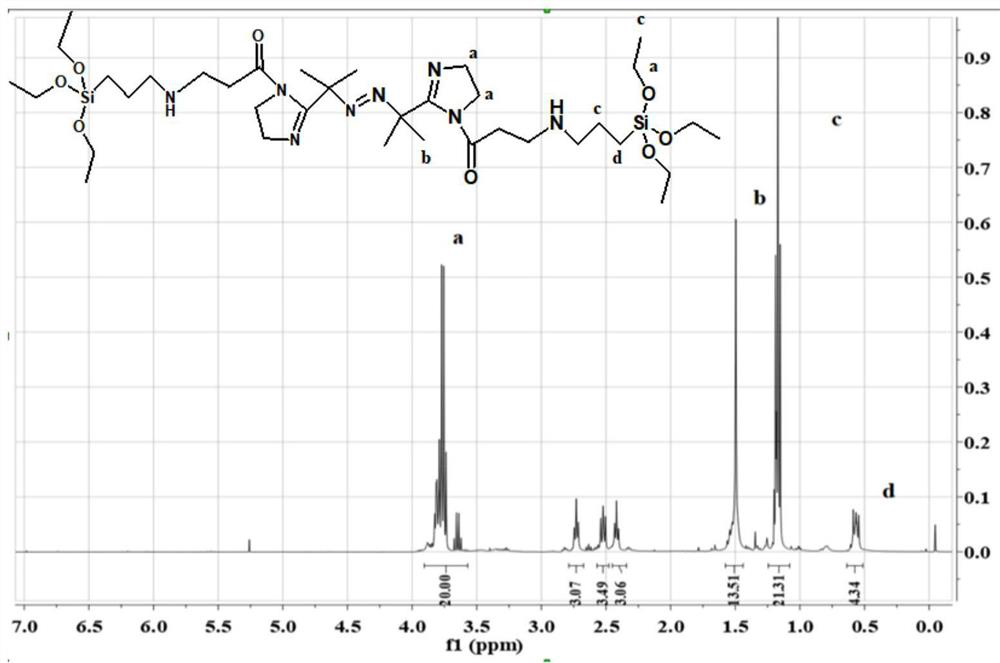

[0040] (2) Dissolve the acylated azo initiator and general silane coupling agent in an organic reagent, mix them into a single-necked flask, stir and react at room temperature for 4-8 h, concentrate and dry to obtain a thermally responsive silane coupling agent,

[0041] In step (1), the azo initiators described are V-50, VA-044, VA-064B, V-501, VA-060, VA-061, VA-057, VA...

Embodiment 1

[0045] 1. Desalination of VA-044

[0046] Azobisisobutylimidazoline hydrochloride (18.6mM, 6g) and sodium hydroxide (92.9mM, 3.7g) were dissolved in 60mL deionized water and added to a 100mL single-neck flask, and the reaction was stirred at room temperature for 2h; after the reaction was over Chloroform was added for extraction, dried over anhydrous sodium sulfate, concentrated by rotary evaporation, and the solvent was removed to obtain 4.2 g of a desalted product, azobisisobutylimidazoline, with a yield of 90%.

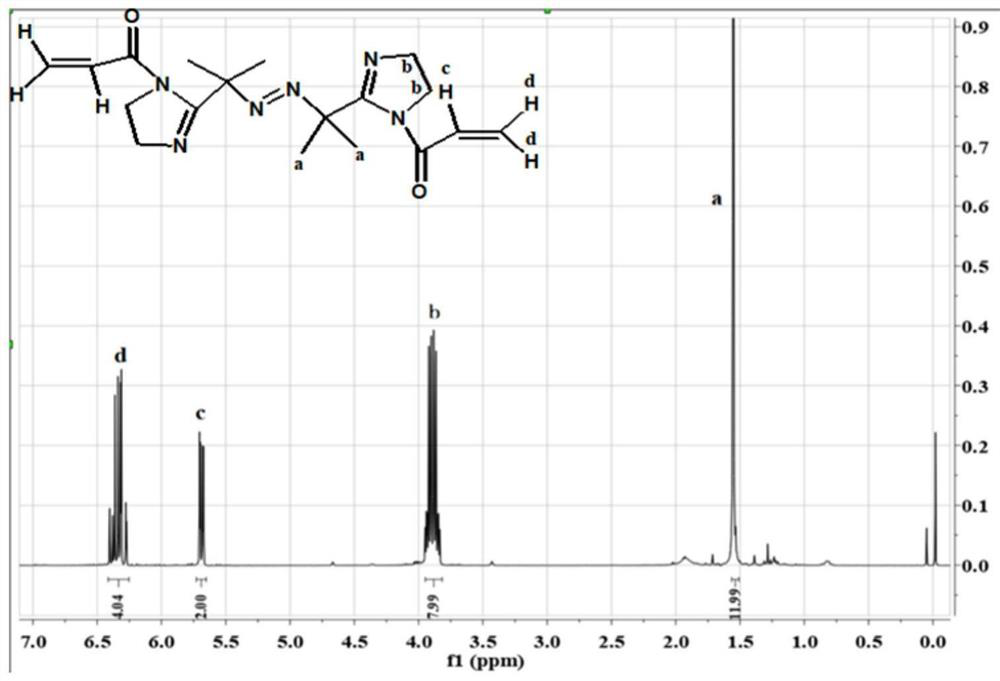

[0047] 2. Preparation of Acylated VA-44

[0048] Azobisisobutylimidazoline (4.0mM, 1.0g) and triethylamine (14.4mM, 1.5g) were dissolved in 100mL of chloroform and added to a three-necked flask, and then acryloyl chloride (12mM, 1.1g dissolved in 20mL of chloroform) was added dropwise. g), the reaction was stirred in an ice-water bath for 15h, and the reaction was carried out under the protection of nitrogen; after the reaction, the solution was washed with alkali...

Embodiment 2

[0054] 1. Desalination of VA-044

[0055] Azobisisobutylimidazoline hydrochloride (18.6mM, 6g) and sodium hydroxide (92.9mM, 3.7g) were dissolved in 60mL deionized water and added to a 100mL single-neck flask, and the reaction was stirred at room temperature for 2h; after the reaction was completed Chloroform was added for extraction, dried over anhydrous sodium sulfate, concentrated by rotary evaporation, and the solvent was removed to obtain 4.2 g of a desalted product, azobisisobutylimidazoline, with a yield of 90%.

[0056] 2. Preparation of Acylated VA-44

[0057] Azobisisobutylimidazoline (4.0mM, 1.0g) and triethylamine (14.4mM, 1.5g) were dissolved in 100mL of chloroform and added to a three-necked flask, and then acryloyl chloride (12mM, 1.1g dissolved in 20mL of chloroform) was added dropwise. g), the reaction was stirred in an ice-water bath for 15h, and the reaction was carried out under the protection of nitrogen; after the reaction, the solution was washed with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com