Epoxy asphalt steel slag concrete ultrathin wearing course and preparation method thereof

A technology of steel slag concrete and epoxy asphalt, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of hindering the development of steel slag solid waste recycling, large pore ratio of steel slag, and high water absorption. Achieve the effect of meeting the requirements of anti-rutting, high tensile strength and improved skid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

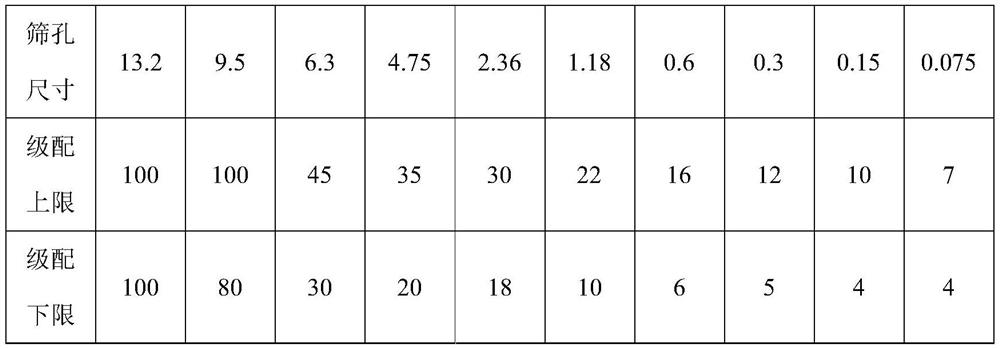

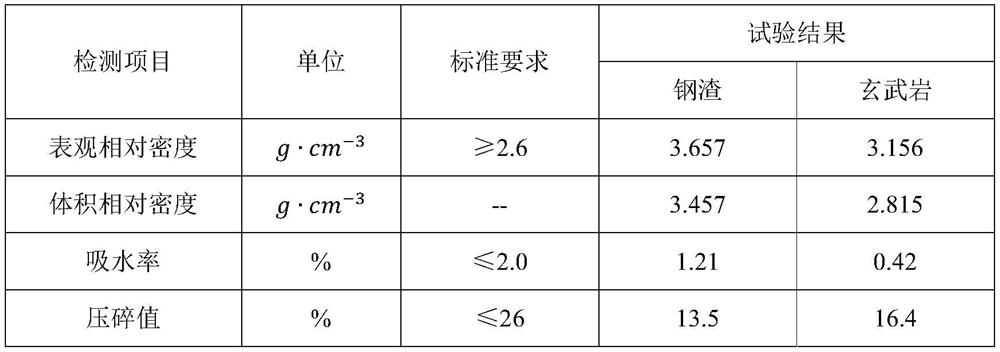

[0044] 100 aggregates. The fine aggregate is limestone with a specification of 0-3mm, totaling 30 parts; the coarse aggregate is modified waterproof steel slag and basalt, with a specification of 5-10mm, totaling 68 parts, of which the modified waterproof steel slag is 40.8 parts and the basalt is 27.2 parts. parts; mineral powder specification is 0-0.6mm, a total of 2 parts. The test results of various properties in the aggregate are shown in Table 1-Table 4.

[0045] Table 1 Test results of steel slag and basalt coarse aggregate

[0046]

[0047]

[0048] Table 2 Chemical composition of steel slag aggregates

[0049] Element CaO SiO2 Al2O3 MnO MgO FeO other Mass ratio % 48.56 13.28 8.53 4.35 8.93 13.35 3

[0050] Table 3 Limestone fine aggregate experimental results

[0051] Test items unit standard requirement test results apparent relative density -- ≥2.5 2.658 sturdiness % ≤12 (more than 0.3m...

Embodiment 2

[0077] 100 aggregates. The fine aggregate is limestone with a specification of 0-3mm, totaling 26 parts; the coarse aggregate is modified waterproof steel slag and basalt, with a specification of 5-10mm, totaling 72 parts, of which the modified waterproof steel slag is 43.2 parts and basalt is 28.8 parts parts; mineral powder specification is 0-0.6mm, 2 parts. The quality components and various properties of aggregate, silicone waterproofing agent, ethylene terephthalate fiber, and epoxy asphalt are the same as those in Example 1.

[0078] See Table 10 for mineral gradation:

[0079] Table 10 embodiment 2 mineral material gradation table

[0080] Sieve hole(mm) 13.2 9.5 6.3 4.75 2.36 1.18 0.6 0.3 0.15 0.075 Passing rate(%) 100 89.3 36.0 29.8 25.0 16.5 12.1 9.6 6.8 5.4

[0081] The preparation method of the epoxy asphalt steel slag concrete ultra-thin wear layer of the present embodiment is the same as that in Example 1, and the prepare...

Embodiment 3

[0085] 100 aggregates. The fine aggregate is limestone with a specification of 0-3mm, totaling 21 parts; the coarse aggregate is modified waterproof steel slag and basalt, with a specification of 5-10mm, totaling 76 parts, of which the modified waterproof steel slag is 45.6 parts and the basalt is 30.4 parts parts; mineral powder specification is 0-0.6mm, a total of 3 parts. The quality components and various properties of aggregate, silicone waterproofing agent, ethylene terephthalate fiber, and epoxy asphalt are the same as those in Example 1.

[0086] See Table 12 for ore grades:

[0087] Table 12 Example 3 mineral material gradation table

[0088] Sieve hole(mm) 13.2 9.5 6.3 4.75 2.36 1.18 0.6 0.3 0.15 0.075 Passing rate(%) 100 88.7 32.4 25.8 21.3 14.6 11.3 9.2 6.7 5.3

[0089] The preparation method of the epoxy asphalt steel slag concrete ultra-thin wear layer of the present embodiment is the same as that in Example 1, and the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Methylene blue value | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com