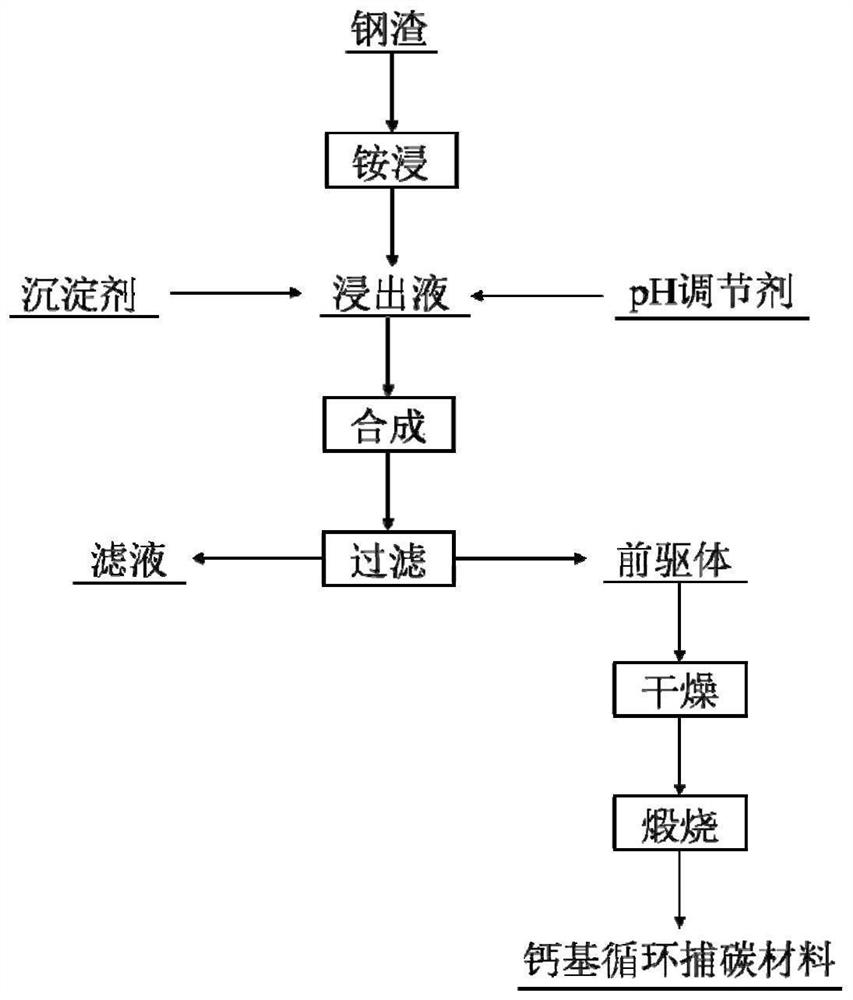

Method for preparing calcium-based cyclic carbon capture material from steel slag

A carbon material and steel slag technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve problems such as high cost, limited adsorption capacity, and long preparation process, and achieve strong cyclic adsorption capacity and high resource utilization , The effect of strong regeneration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Step 1: in the process of producing slag by smelting the chromium-containing steel slag, add pyrolusite with a mass of 6% of the steel slag, and cool it to 20° C. after the slag is finished.

[0055] Step 2: Crushing and ball milling the modified steel slag in a crusher and a ball mill, screening the steel slag with a 200-mesh sieve, and weighing 200 g of the steel slag under the 200-mesh sieve as a raw material. Add NH with a volume of 1.5L and a concentration of 2mol / L 4 Cl solution ammonium immersion, the ammonium immersion time is 2.5h, the ammonium immersion temperature is 40°C, the stirring rate is 400rpm, the ultrasonic oscillation power is 300W, and the ultrasonic frequency is 20KHz. After leaching, filter to obtain calcium and magnesium rich filtrate.

[0056] Step 3: Add (NH) with a concentration of 2 mol / L to the filtrate of step 2 4 ) 2 CO 3 solution and added NH 4 The pH value of the OH-adjusted solution was 9.8, the stirring rate was 400 rpm, the reac...

Embodiment 2

[0061] Step 1: In the process of producing slag by smelting the chromium-containing steel slag, add pyrolusite with a mass of 7% of the steel slag and 7% of magnesia brick waste, and cool it to 35°C after the slag is discharged.

[0062] Step 2: crush and ball mill the modified steel slag in a crusher and a ball mill, screen the steel slag with a 200-mesh sieve, and weigh 100 g of the steel slag under the 200-mesh sieve as a raw material. Add NH with a volume of 1.5L and a concentration of 1.5mol / L 4 NO 3 The solution was immersed in ammonium, the ammonium immersion time was 1h, the ammonium immersion temperature was 50°C, the stirring rate was 500rpm, the ultrasonic oscillation power was 300W, and the ultrasonic frequency was 20KHz. After leaching, filter to obtain calcium and magnesium rich filtrate.

[0063] Step 3: Add NH with a concentration of 1 mol / L to the filtrate of step 2 4 HCO 3 solution and added NH 4 OH adjusts the pH value of the solution to 10, the stirrin...

Embodiment 3

[0068] Step 1: in the process of producing slag by smelting the chromium-containing steel slag, add high alumina brick waste with a mass of 10% of the steel slag, and cool it to 50°C after the slag is finished.

[0069] Step 2: crush and ball mill the modified steel slag in a crusher and a ball mill, screen the steel slag with a 200-mesh sieve, and weigh 100 g of the steel slag under the 200-mesh sieve as a raw material. Add CH with a volume of 800 mL and a concentration of 3 mol / L 3 COONH 4 The solution was immersed in ammonium, the ammonium immersion time was 3h, the ammonium immersion temperature was 65°C, the stirring rate was 400rpm, the ultrasonic oscillation power was 400W, and the ultrasonic frequency was 25KHz. After leaching, filter to obtain calcium and magnesium rich filtrate.

[0070] Step 3: Add NH with a concentration of 2 mol / L to the filtrate of step 2 4 HCO 3 solution and added NH 4 The pH value of the OH-adjusted solution was 8.9, the stirring rate was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com