Application of red algae starch

A technology of red algae starch and red algae, applied in the direction of food science, etc., can solve the problems that have not been reported, and achieve the effect of improving blood sugar index, low production cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 100 g of dried and crushed Astragalus algal powder, add 2 L of 1 mol / L acetic acid, soak for 1 hour at room temperature, centrifuge, discard the supernatant, and wash the treated algal mud with deionized water until neutral. Re-add 2L of deionized water, leaching in a 100°C water bath for 2 hours, filter, and concentrate the filtrate to one-fifth of the volume under reduced pressure. Precipitate with 95% ethanol alcohol, stand in a refrigerator at 4° C. for 24 hours, centrifuge, and dissolve the precipitate in 50 ml of deionized water again, discard the insoluble matter, and freeze the solution to obtain kelp starch 1. Its molecular weight was determined to be 4KDa by HPLC.

Embodiment 2

[0022] Weigh 100 g of dried and pulverized unicornis algal powder, add 2 L of 2 mol / L malic acid, soak for 2 hours at room temperature, centrifuge, discard the supernatant, and wash the treated algal mud with deionized water until neutral. Add 2L of deionized water again, leaching in a 70°C water bath for 10 hours, filter, and concentrate the filtrate to one-fifth of the volume under reduced pressure. Precipitate with 95% ethanol alcohol, let stand in a refrigerator at 4° C. for 24 hours, centrifuge, and dissolve the precipitate in 50 ml of deionized water again, discard insoluble matter, and freeze the solution to obtain kelp starch 2. Its molecular weight was determined to be 5KDa by HPLC.

Embodiment 3

[0024] Weigh 100 g of dried and crushed centipede algal powder, add 2 L of 0.5 mol / L citric acid, soak at room temperature for 4 hours, centrifuge, discard the supernatant, and wash the treated algal mud with deionized water until neutral. Add 2L of deionized water again, leaching in a 90°C water bath for 5 hours, filter, and concentrate the filtrate to one-fifth of the volume under reduced pressure. Precipitate with 95% ethanol alcohol, let stand in a refrigerator at 4° C. for 24 hours, centrifuge, and dissolve the precipitate in 50 ml of deionized water again, discard insoluble matter, and freeze the solution to obtain kelp starch 3 . Its molecular weight was determined to be 2.5KDa by HPLC.

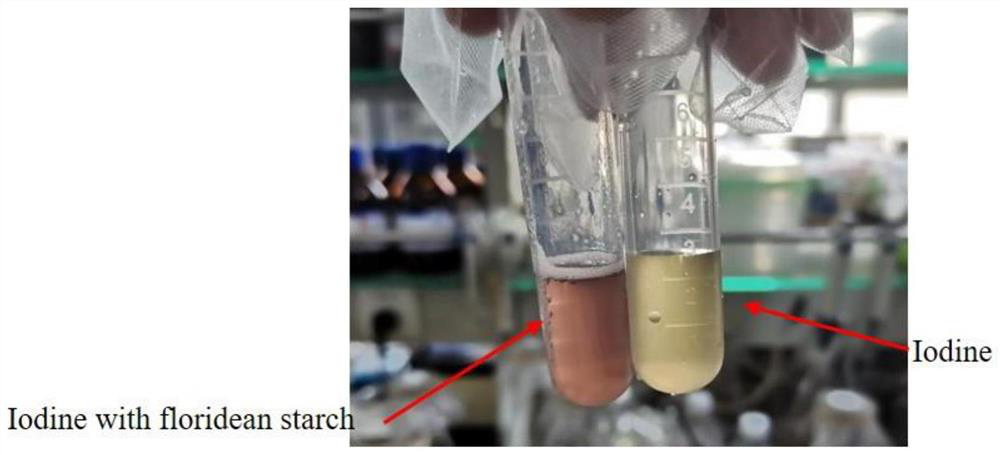

[0025] Further verify the above-mentioned obtained alginate, take the kainate 3 obtained in Example 3 as an example to carry out the iodine color development reaction, and the iodine solution becomes reddish brown, such as figure 1 As shown, it was proved to be red alginate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com