Solid-liquid combined peracetic acid disinfectant and preparation method thereof

A technology of peracetic acid and disinfectant, which is applied in botany equipment and methods, disinfectant, and resistance to vector-borne diseases. It can solve the problems of strong odor, strong corrosiveness, and high logistics cost, and achieve odor reduction and stability. Strong, the effect of saving logistics costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] S1. Weigh 160 g of 50% hydrogen peroxide raw material, 0.3 g of EDTA, 0.05 g of benzotriazole, 0.5 g of disodium hydrogen phosphate and 836.55 g of purified water to form A liquid.

[0039] S2. Weigh 1.0 g of TAED, 0.05 g of defoamer, 0.05 g of sodium dodecylbenzene sulfonate, and 1.5 g of sodium carbonate to form B powder;

[0040] Add the raw materials of liquid A into the batching tank, stir for 1 hour, and mix the raw materials evenly.

[0041] The raw material powders of S4 and B powder are added to the mixer, and mixed for 25-30 minutes under normal temperature conditions, so that the raw materials are fully mixed evenly;

[0042] S5, package the materials of liquid A and powder B respectively.

[0043] S6. When using, add powder B into solution A and stir to dissolve powder B completely, and generate enough peracetic acid at the same time, and then dilute with purified water until the content of peracetic acid is greater than 0.2%.

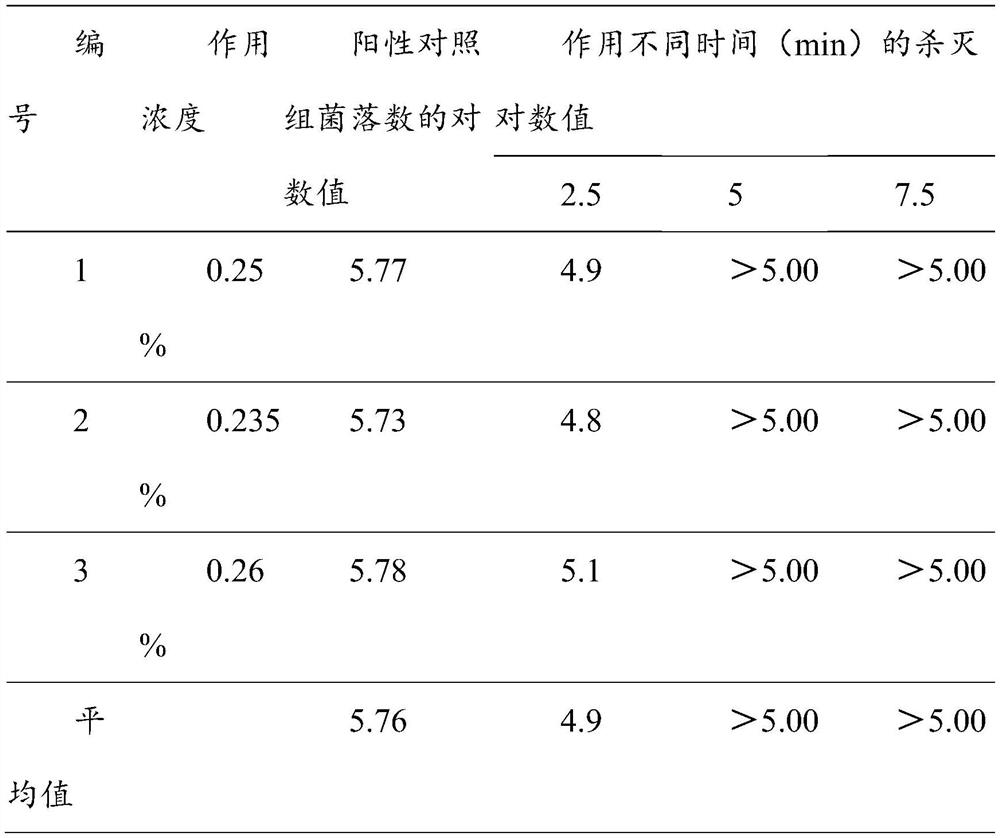

[0044] 1) Stability:

[00...

Embodiment 2

[0073] S1. Weigh 180 g of 50% hydrogen peroxide raw material, 0.5 g of disodium HEDP, 0.1 g of benzotriazole, 0.3 g of trisodium phosphate and 814.8 g of purified water to form A liquid.

[0074] S2, weigh 2.0g of sodium acetylsalicylate, 0.05g of defoamer, 0.3g of sodium dodecylbenzenesulfonate, and 2.0g of sodium bicarbonate to form B powder;

[0075] S3. Add the raw materials of liquid A into the batching tank, and stir for 1 hour to make the materials evenly mixed.

[0076] The raw material powders of S4 and B powder are added to the mixer, and mixed for 25-30 minutes under normal temperature conditions, so that the raw materials are fully mixed evenly;

[0077] S5, package the materials of liquid A and powder B respectively.

[0078] S6. When using, add powder B into solution A and stir to dissolve powder B completely, and generate enough peracetic acid at the same time, and then dilute with purified water until the content of peracetic acid is greater than 0.2%.

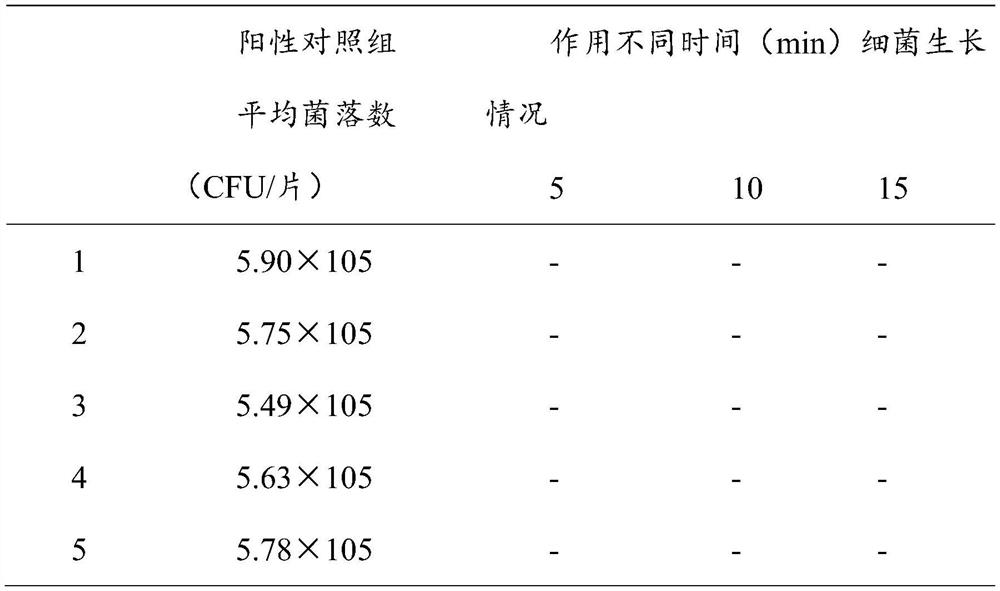

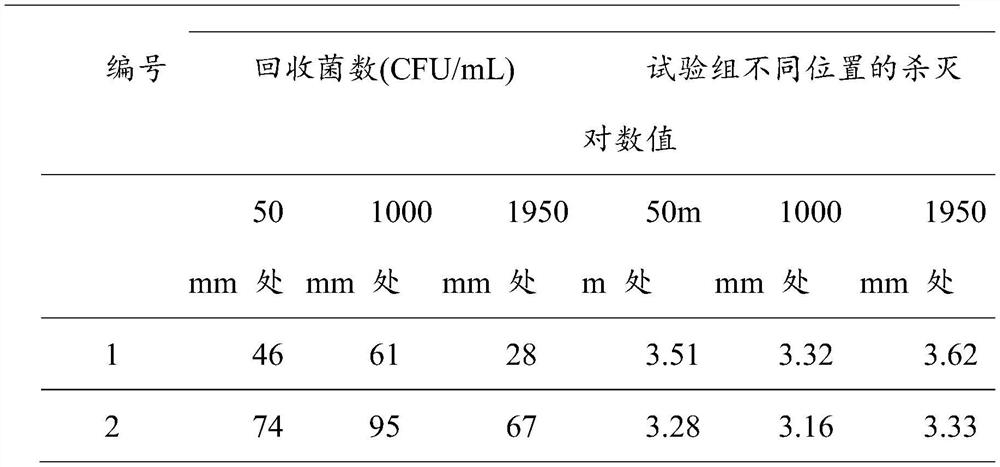

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com