Simple and green method for preparing high-purity porous aluminum foil and application of method in sodium battery

A high-purity, aluminum foil technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of large environmental pollution and high production area requirements, and achieve the effect of simple and easy process, improved utilization rate, and accelerated volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A simple and green method for preparing high-purity porous aluminum foil:

[0042] Configuration plating solution: 0.5M zinc sulfate + 0.1M ammonium sulfate + 0.01M cetyltrimethylammonium bromide

[0043] Place commercial aluminum foil in the plating solution at 0.5 mA cm -2 Electroplating for 5 hours at the current density of 100 °C, then put into a tube furnace, heated at 200 °C for 5 hours under a vacuum pressure of -0.1 MPa, and then heated to 500 °C for 10 hours. After cooling, high-purity porous aluminum foil can be obtained.

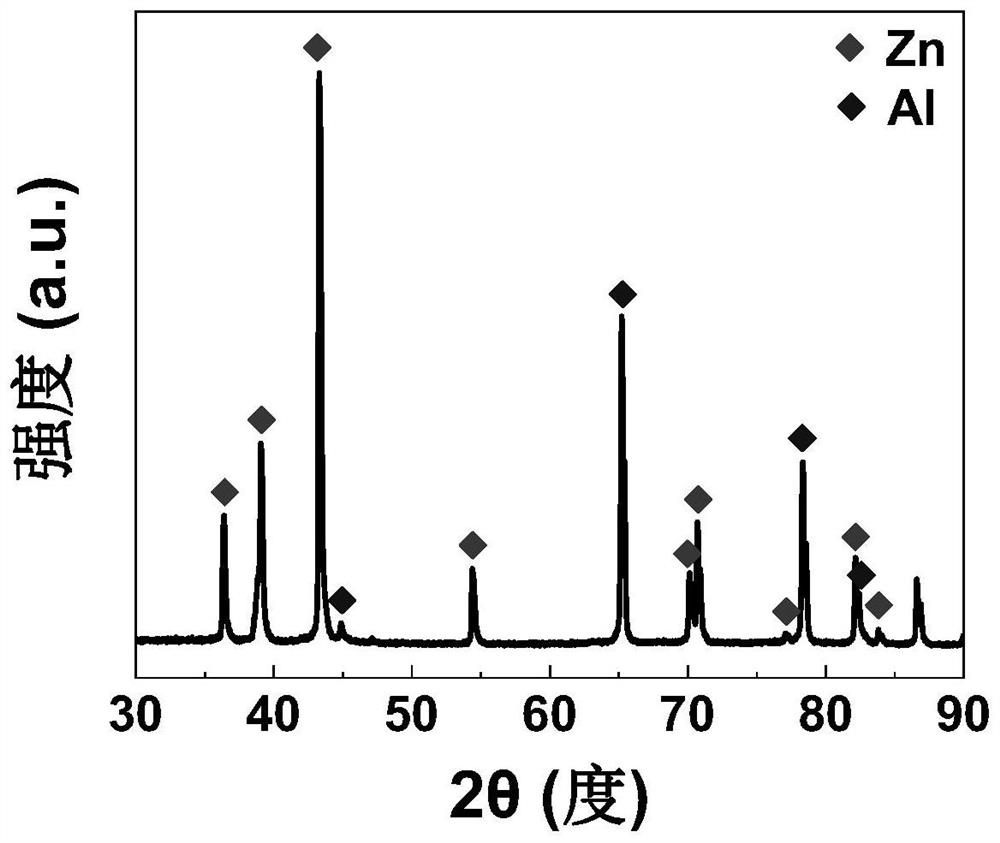

[0044] figure 1 It is the XRD pattern of the zinc-aluminum alloy in Example 1. The characteristic peaks of zinc and aluminum are observed, indicating that the metal zinc is successfully plated on the aluminum foil.

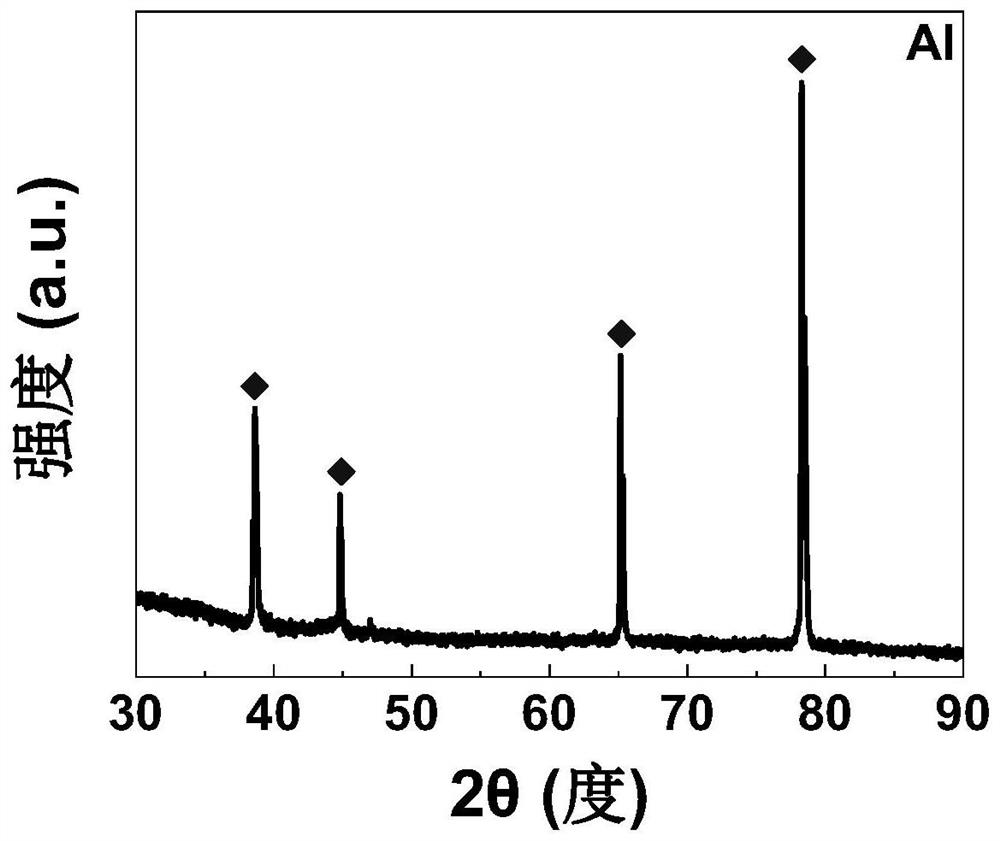

[0045] figure 2 This is the XRD pattern of the porous aluminum in Example 1. The characteristic peaks of aluminum are observed, and there are no other impurity peaks, indicating that the prepared porous aluminum has high pu...

Embodiment 2

[0048] A simple and green method for preparing high-purity porous aluminum foil:

[0049] Configuration plating solution: 0.5M zinc sulfate + 0.12M ammonium sulfate + 0.01M cetyltrimethylammonium bromide

[0050] Place commercial aluminum foil in the plating solution at 0.4 mA cm -2 Electroplating for 6 hours at a current density of 100%, then placed in a tube furnace, heated at 180 °C for 5 hours under a vacuum pressure of -0.12 MPa, and then heated to 500 °C for 10 hours. After cooling, high-purity porous aluminum foil can be obtained.

Embodiment 3

[0052] A simple and green method for preparing high-purity porous aluminum foil:

[0053] Configuration plating solution: 1.0M zinc sulfate + 0.15M ammonium sulfate + 0.014M cetyltrimethylammonium bromide

[0054] Place commercial aluminum foil in the plating solution at 0.2 mA cm -2Electroplating for 4 hours at the current density of 100%, then put into a tube furnace, heated at 200 °C for 5 hours under a vacuum pressure of -0.1MPa, and then heated to 480 °C for 9.5 hours at a vacuum pressure of -0.2MPa, after cooling, you can Obtain high-purity porous aluminum foil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com