Thuja koreana test analysis equipment

An analysis equipment and technology of Thuja, which is applied in the field of test and analysis equipment of Thuja in North Korea, can solve the problems of insoluble solid particles, changing the internal volume of the stirring device, and considering contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

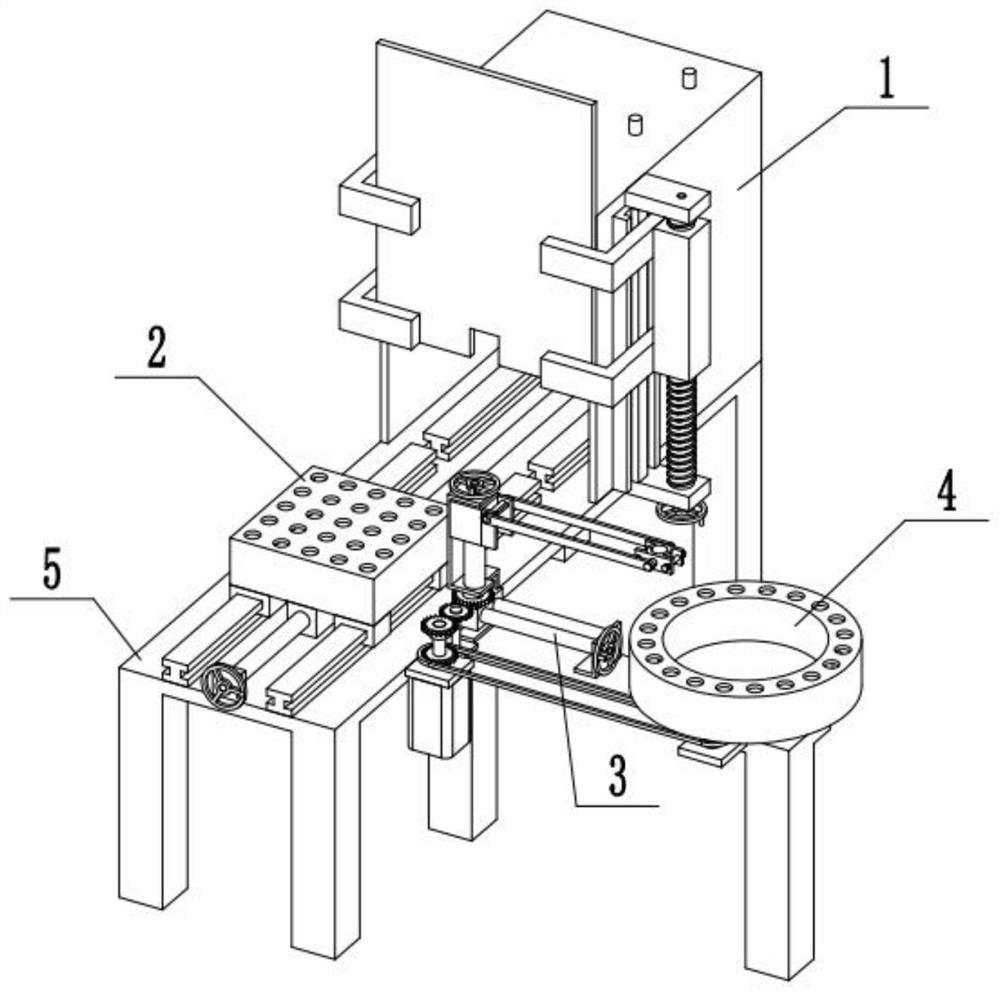

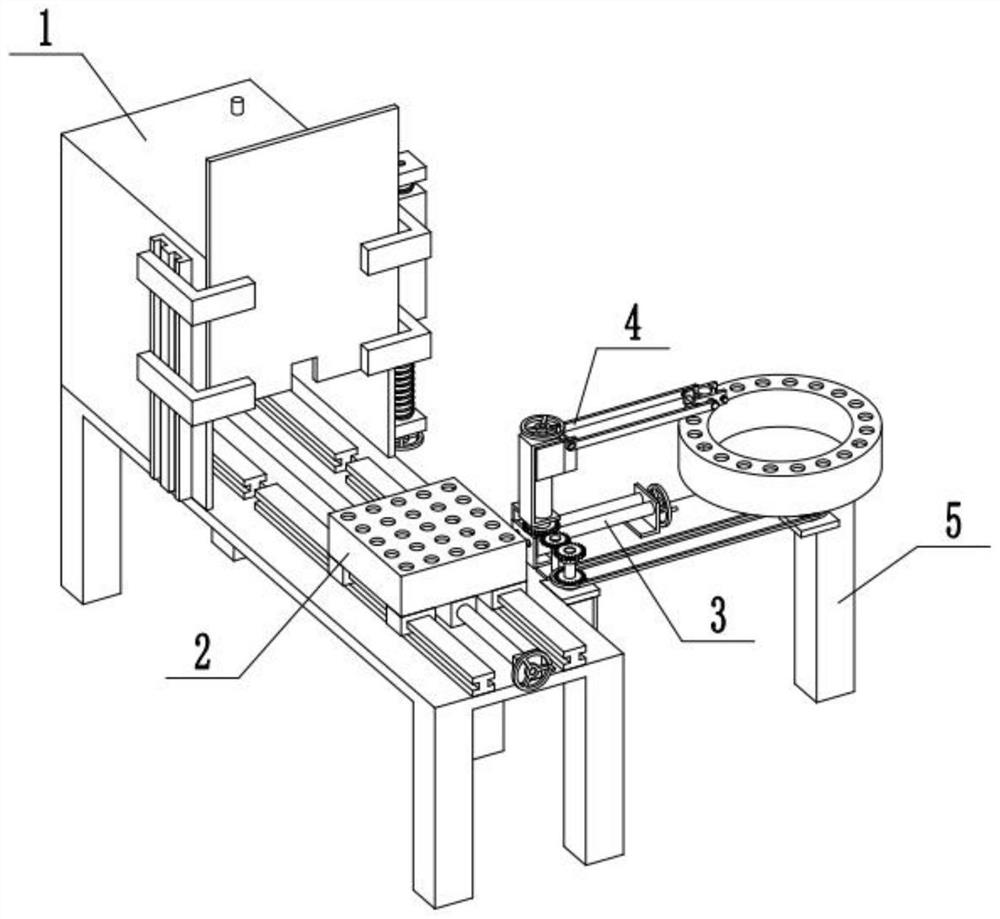

[0029] Combine below Figure 1-13 Illustrating this embodiment, a Korean Thuja test and analysis equipment includes a sterilizing device 1, a moving device 2, a back-pulling device 3, a transferring device 4, and a base 5. The sterilizing device 1 is connected to the base 5, and the moving device 2 is connected to the base 5. The base 5 is connected, the back pulling device 3 is connected with the base 5, the back pulling device 3 is connected with the transfer device 4, and the transfer device 4 is connected with the base 5.

specific Embodiment approach 2

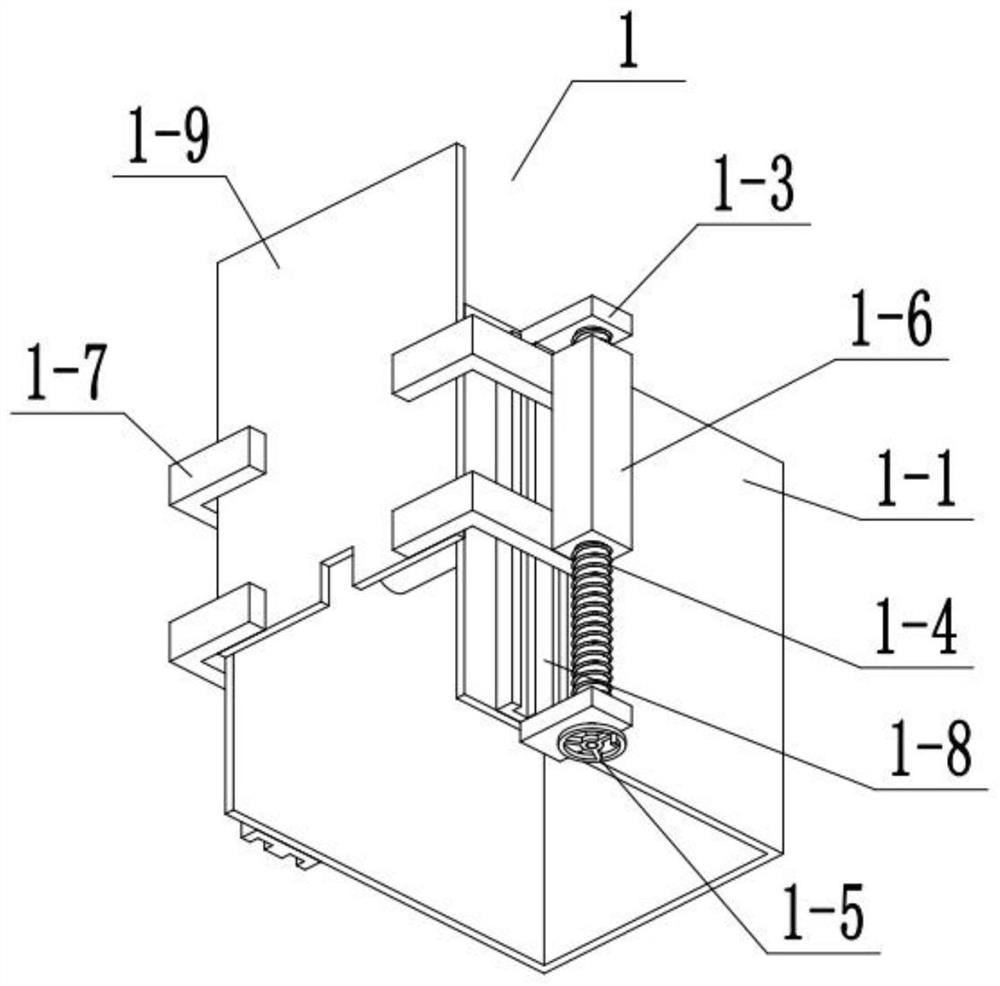

[0030] Combine below Figure 1-13This embodiment will be described. This embodiment will further describe the first embodiment. The sterilization device 1 includes a sterilization cover 1-1, an ultraviolet lamp 1-2, a sliding door screw seat 1-3, and a sliding door screw 1-4. , sliding door handle 1-5, sliding door wire sleeve 1-6, sliding door connecting seat 1-7, sliding door slider 1-8, sterilization door 1-9, ultraviolet lamp 1-2 and sterilization cover 1-1 Fixed connection, the sliding door screw seat 1-3 is welded with the sterilization cover 1-1, the sliding door screw 1-4 is connected with the sliding door screw seat 1-3 in rotation, and the sliding door handle 1-5 is connected with the sliding door wire Rod 1-4 is fixedly connected, the sliding door screw sleeve 1-6 is threadedly connected with the sliding door screw rod 1-4, the sliding door screw sleeve 1-6 is welded with the sliding door connecting seat 1-7, and the sliding door connecting seat 1-7 It is slidingly...

specific Embodiment approach 3

[0031] Combine below Figure 1-13 This embodiment will be described. This embodiment will further describe Embodiment 1. The moving device 2 includes a moving handle 2-1, a moving screw rod 2-2, a moving screw sleeve 2-3, a test tube rack 2-4, and a moving slider. 2-5. Move the slide rail A2-6, move the slide rail B2-7, the moving handle 2-1 is fixedly connected with the moving screw rod 2-2, the moving screw sleeve 2-3 is threadedly connected with the moving screw rod 2-2, the test tube The rack 2-4 is fixedly connected with the moving wire sleeve 2-3, the moving slider 2-5 is fixedly connected with the test tube rack 2-4, and the moving slider 2-5 is respectively connected with the moving rail A2-6 and the moving rail B2-7 Sliding connection, turn the moving handle 2-1 to drive the moving screw rod 2-2 to rotate, so that the moving screw sleeve 2-3 drives the test tube rack 2-4 to move along the moving slide rail A2-6 and move under the action of the moving slider 2-5. Slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com