Power station water vapor system pH measurement self-calibration method and measurement calibration system

A calibration system and self-calibration technology, which is applied in the field of analysis and detection, can solve the problems of increasing the workload of maintenance personnel, time-consuming pH meter calibration methods, frequent calibration cycles, etc., to achieve easy popularization and application, improve accuracy and stability, and The long-term effect

Pending Publication Date: 2022-07-29

HUANENG BEIJING CO GENERATION

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Although the current online pH meter measurement method can realize the control of the pH of the water vapor system, the traditional pH meter calibration method is not only time-consuming but also easily introduces calibration errors due to improper operation.

The specific reason is that the existing on-line pH measurement uses the glass electrode method, and the electrode often needs to be calibrated to ensure the accuracy of pH measurement. This calibration method mainly has the following disadvantages: (1) The calibration cycle is frequent, and the general maintenance personnel need to regularly Calibrate once, as the electrode usage time increases, the calibration cycle will be more frequent, which will increase the workload of maintenance personnel; (2) The calibration process is complicated, and maintenance personnel need to prepare a calibration solution in the laboratory, which may expire, so It is also necessary to configure a new solution regularly, and then take the electrode out of the flow cell of the meter and put it into the calibration solution for calibration according to the calibration procedure; (3) This calibration method itself has the risk of introducing calibration errors, because the calibration solution is generally poured directly Into the open beaker, and then insert the electrode, at this time in the process of performing the calibration procedure, the carbon dioxide in the air will dissolve into the calibration solution to form carbonic acid, resulting in changes in the acidity and alkalinity of the calibration solution itself

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

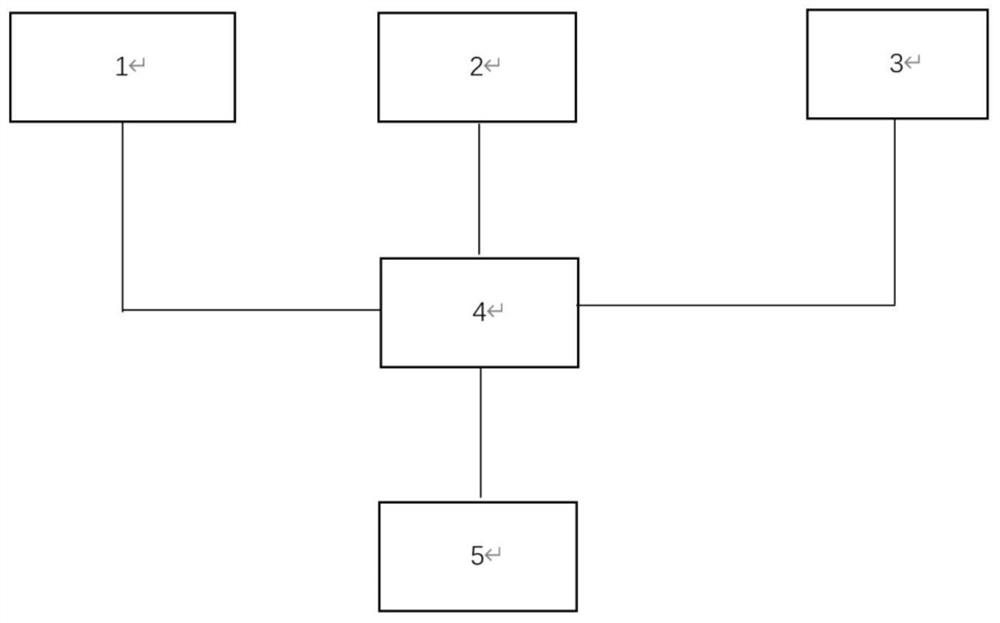

[0023] see figure 1 , The pH measurement and calibration system of the water vapor system of the power station provided by this embodiment includes a pH calibration device 4 and a hydrogen conductivity electrode 1 , a conductivity electrode 2 and a pH electrode 3 respectively connected to the pH calibration device 4 . Also included is a display device 5 connected to the pH calibration device 4 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Login to View More

Abstract

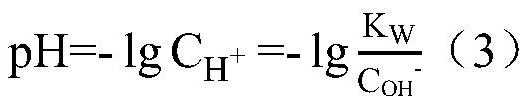

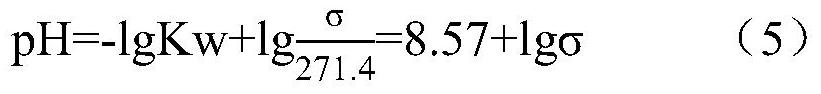

The invention belongs to the technical field of analysis and detection, and relates to a power station water vapor system pH measurement self-calibration method and measurement calibration system.The method comprises the following steps that 1, the hydrogen conductivity value, the conductivity value sigma and the pH measurement value of a water sample are detected respectively and transmitted to a control device; 2) when the hydrogen conductivity value is greater than 0.3 [mu] S / cm, the control device extracts a pH value signal and directly outputs the pH value signal, and sends out a manual calibration prompt; and when the hydrogen conductivity value is smaller than 0.3 [mu] S / cm, the control device extracts a conductivity value signal, calculates a pH calculated value according to the pH value of 8.57 + lg sigma, calibrates the pH measured value by using the pH calculated value, and sends out a prompt for starting the automatic calibration of the pH value. According to the invention, the automatic calibration of the pH measurement result can be realized, the accuracy of the measurement result is ensured, the regular calibration period is long, and the daily maintenance is simple.

Description

technical field [0001] The invention belongs to the technical field of analysis and detection, and relates to a pH measurement self-calibration method and a measurement calibration system of a water vapor system of a power station. Background technique [0002] In the operation of the power station, since the acidity of the water vapor system will cause corrosion to the thermal equipment and pipelines, the treatment method of adding ammonia water at the ammonia adding point is generally used to improve the alkalinity of the water, so as to achieve the purpose of anti-corrosion. Therefore, it is necessary to test the pH in actual operation. At present, most power stations install online pH meters at the feedwater measuring points after ammonia addition, so as to monitor the changes of water pH in real time. [0003] Although the current online pH meter measurement method can realize the control of the pH of the water vapor system, the traditional pH meter calibration method i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N27/06

CPCG01N27/06

Inventor 崔伟强解育才杨承江杨智李建超杨君君朱富强陈思卓何尧年夏春雷孙立成尚艳峰赵华金张旺杨佳宝王莉程志卓李晓宇杨万鑫肖鹤鹏徐滔

Owner HUANENG BEIJING CO GENERATION

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com