Intelligent detection method for quality of fabricated building connection node

A technology for connecting nodes and intelligent detection, applied in the direction of measuring devices, character and pattern recognition, instruments, etc., can solve problems such as hindering the informatization and intelligentization of the construction industry, unable to ensure construction quality from the source, and reducing the accuracy of detection results. , to improve the recognition accuracy and detection efficiency, easy to popularize and use, and avoid human errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

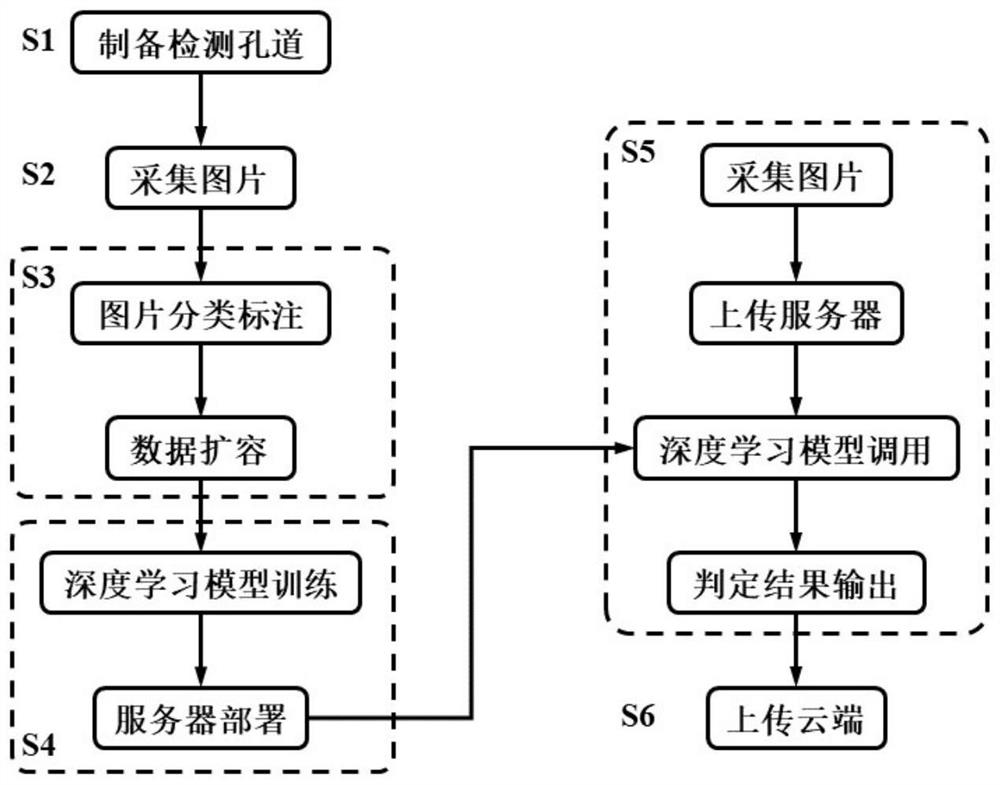

[0040] Embodiment 1: For multiple projects of assembling integral concrete shear wall structures, this method is used to track and detect the whole process of sleeve grouting. The process is as follows: figure 1 shown, including the following steps:

[0041] A large number of grouting sleeves are selected as the sample set, and a percussion drill is used to drill holes at the grouting outlet of the sleeve to form detection holes.

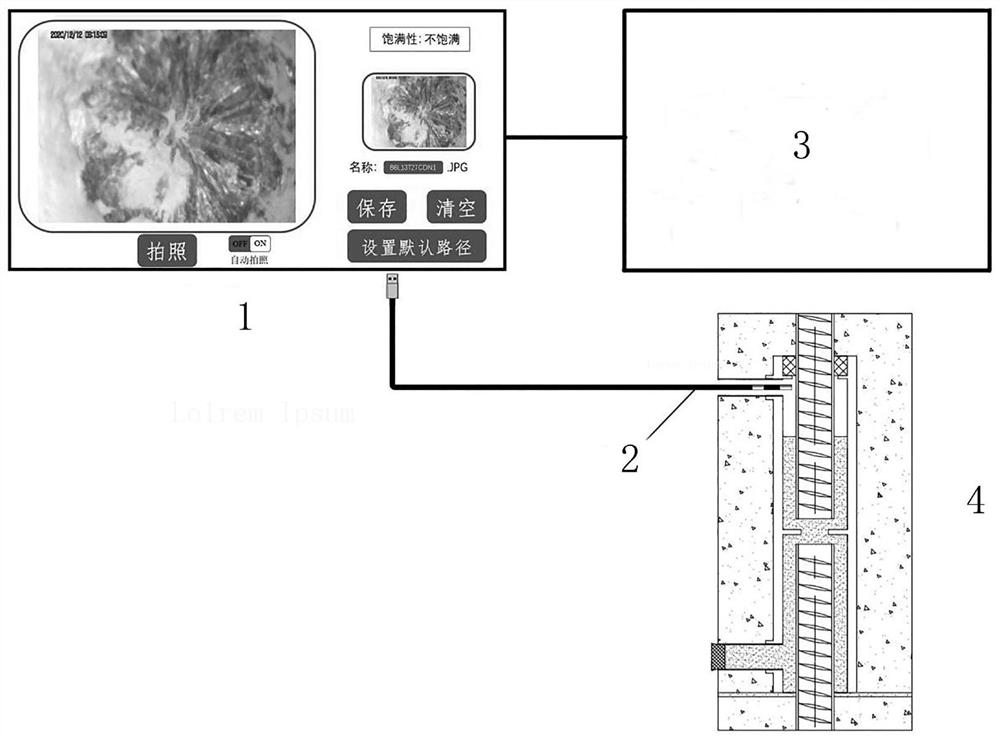

[0042] Insert the monocular endoscope into the detection hole, operate the handheld device to observe the grouting inside the sleeve and collect pictures.

[0043]The collected pictures are classified and marked, and the fullness of the sleeve grouting is divided into three categories according to the classification rules of fullness, lack of fullness and indecision. Among them, the special conditions of blockage and fracture in the sleeve are regarded as inoperable. . Limited by the number of sleeves available for detection, the collected data se...

Embodiment 2

[0048] Embodiment 2: The process of neural network training and detection is as follows figure 1 shown, the specific steps are as follows:

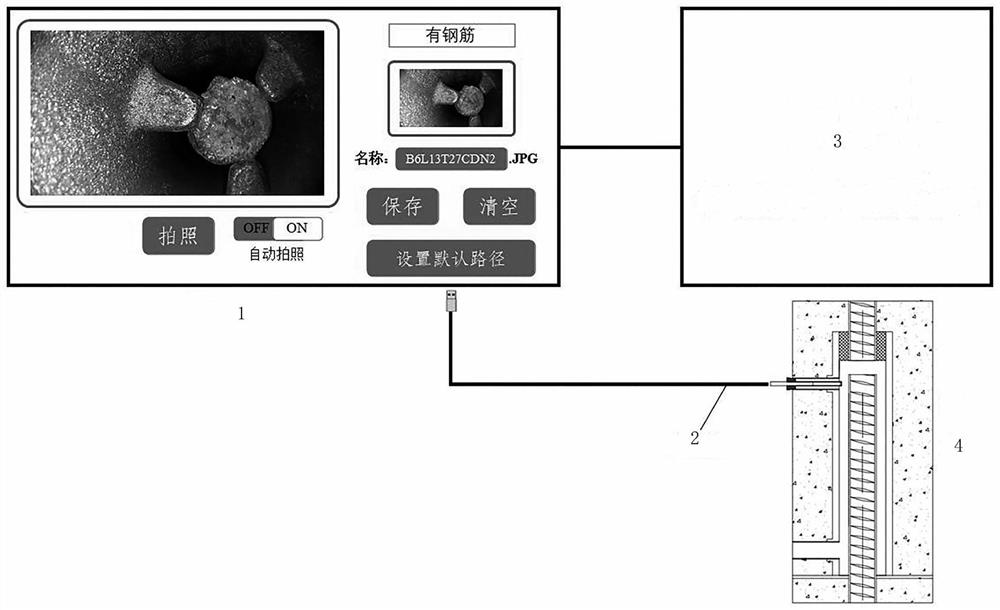

[0049] A large number of grouting sleeves 4 are selected as the sample set, and the endoscope is inserted into the grouting outlet to take pictures of the internal environment of the sleeves. The collected pictures are classified and marked, and the insertion states of steel bars are divided into two categories according to the classification rules of those with steel bars and those without steel bars. Similar to the first embodiment, the image expansion operation and the data set division are performed. Afterwards, the deep learning model is trained, and the trained deep learning model is deployed on the server.

[0050] During the inspection, the worker will carry out the inspection with the handheld device and the endoscope, and operate the endoscope to extend into the slurry outlet channel of the sleeve to observe the insertion stat...

Embodiment 3

[0054] Embodiment 3: The present invention provides an intelligent detection method for the quality of a connection node of a prefabricated building. The operating software can be written as a mobile device APP and installed in a mobile phone or tablet computer. APP interface such as Figure 4 As shown, the APP can complete the functions of the visual interface in the first embodiment and the second embodiment, and realize human-computer interaction. When the mobile terminal runs and displays the APP, the APP executes the corresponding function according to the detected manual touch or voice operation of the worker. The APP includes two major functional modules, namely, the sleeve grouting fullness detection module and the steel bar insertion state detection module. The specific usage method can refer to the operation method of the visual interface in the first embodiment, and the detection results are also uploaded to the cloud database to generate Test Report.

[0055] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com